Current highway design codes require a bridge to last 75 years.

But heritage bridges prized by their communities are often expected to last forever.

So, what’s the best way to keep them going?

Two communities in southwestern Ontario have recently wrestled with this very question in connection with historic bridges in their downtowns and each has taken a different approach to rehabilitation.

In St. Marys, near Stratford, the solution for last year’s rehabilitation of the Water Street Bridge involved convincing the Upper Thames River Conservation Authority to lower the water level of the river that the bridge spans to accommodate in-place construction. Meanwhile, in nearby London, where work begins this fall on the Blackfriars Bridge, plans are to remove the entire structure and rehabilitate it offsite.

In terms of the St. Marys rehabilitation, Jeff Wolfe, an engineering and asset management specialist, said municipal staff knew for quite some time that the heritage bridge was in need of major repair.

Doug MacRae

City of London

"There were concerns about the structural stability," he said.

In 2015, council ruled out replacement in favour of rehabilitation.

"They wanted to see the heritage value of the bridge remain," said Wolfe.

The Stratford Bridge Company built the pin-connected steel truss structure in 1898. Making it functional again required replacing the wooden deck and its steel beam supports.

In mid-August 2016, with an Ontario Community Infrastructure Fund grant in hand, the municipality forged ahead. B.M. Ross and Associates Limited was the project’s design consultant and the town hired McLean Taylor Construction Limited as general contractor. The heavy civil construction contractor is based in St. Marys and, coincidentally, right next to the bridge.

Rather than replace the wooden deck with more wood, the team opted for a prefabricated panel system to extend the life expectancy of the decking. The panels comprise a core of polyurethane elastomer sandwiched by two steel plates.

Fitting these square panels into the truss structure presented a challenge because the bridge wasn’t perfectly square.

"They had to play with some of the beams underneath to make the bolt patterns line up," Wolfe said.

Initially it was thought the truss structure was in good shape but as preparations began for recoating, the contractors found areas needing replacement.

The town had budgeted $600,000 for the project but ended up spending closer to $700,000 by the time work finished in November.

No particular line items stood out for creating the cost overrun, Wolfe said.

"It was just overall the unit costs were higher than what we had anticipated."

Goderich-based B.M. Ross has repaired and rehabilitated several steel truss bridges in southwestern Ontario, and Andrew Ross, the firm’s vice president, said old structures regularly present unique challenges.

For example, just try to find the rivets often used to fasten the steel together. Ross knows of only one company in Michigan that supplies them but he recommends using bolts instead. They give the appearance of rivets but are stronger.

"Also the older steel may not hold the weld very well. The chemical mix in the steel predates welding applications in some cases."

That mix — metal impurities such as chromium and nickel — also makes the old material weaker than modern steel.

However, the mixture does provide better resistance to corrosion and if the bridge is not on a road that receives salt in winter, Ross will forego painting, which can be expensive. In the St. Marys case, however, it was necessary to paint the bridge to protect against winter salt damage.

Heritage played a key role in the choice of paint colour, but the final choice reflects another unusual feature of bridge refurbishment, said Ross: restoration to "people’s memory" rather than the structure’s original condition can often be the priority.

In 1898 colour photography didn’t exist, he explained. Scratching through paint on the Water Street Bridge revealed a light minty green as possibly the original colour. Current residents, however, "remembered it being a dark forest green," and so the darker colour became the choice for the new paint coat.

One of the most dramatic elements of the rehabilitation of the Blackfriars Bridge in London will be its removal by crane.

Doug MacRae, the city’s transportation planning and design division manager, said the approach provides the benefit of continuing work indoors in a controlled environment through winter and reduces concerns about public and worker safety.

"We want a high quality of workmanship that respects the heritage nature of the bridge," he said.

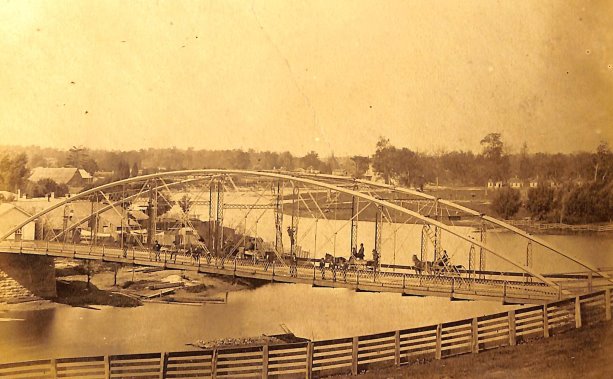

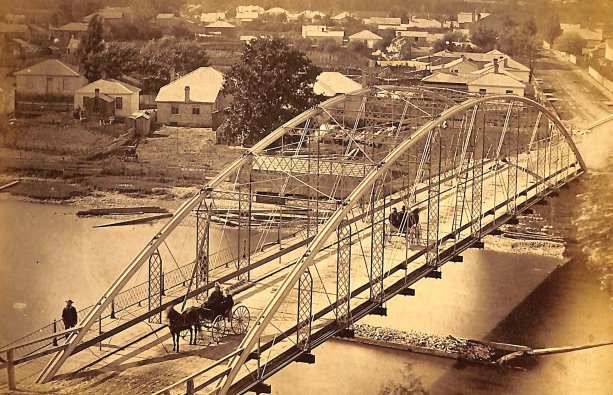

The bridge was built in 1875 by the Wrought Iron Bridge Company of Canton, Ohio and assembled by Isaac Crouse, a London bridge builder. The only known wrought iron bridge in Canada and the longest of its type in North America, Blackfriars is designated under the Ontario Heritage Act and considered a national site by the Canadian Society of Civil Engineers.

The city closed the structure to vehicle traffic in 2013 after a detailed assessment of its structure revealed severe deterioration. An environmental assessment determined historical and local significance made retaining the bridge a priority.

"It’s a real cultural piece for the city," MacRae said. "It can be seen across town in paintings, stained glass windows and carved into trees."

Western University civil engineering professors researched the bridge’s engineering history and Dillon Consulting Limited, which conducted the environmental assessment, supplied the design.

The city proposes using the bridge in both directions for pedestrian and cycling traffic but only allowing eastbound motor vehicle traffic.

Westbound traffic was ruled out because of the way the steeply graded westbound approach directs vehicles to the place where the primary bowstring arch struts meet the abutments.

"If a vehicle in slippery wintry conditions ever lost control and hit that it could lead to a catastrophic failure," MacRae said.

Tender information describes work to include the following components: replacement of the deck and the addition of new deck stringers as well as new horizontal deck bracing; either replacing or reinforcing the vertical hangers that support floor beams and the addition of new floor beams; and the removal of reinforcements added in the 1950s and replacing them with new materials.

The city is looking at switching out the wooden deck with a more durable product, MacRae said. There will be a wooden sidewalk, according to a recent presentation for a public information session.

The presentation also lists plans to add new concrete caps to the abutments and a clearance beam to the bridge to prevent use by over-height vehicles. Other tasks on the list are adding a vehicle turnaround at the western end, adjusting the alignment of the city’s trail system there as well and, on the eastern approach, introducing traffic calming measures.

Pre-qualification of contractors took place earlier this year and a decision on the final tender will be made this summer. The 12-month project is expected to cost millions of dollars. The specific amount depends on the winning tender, MacRae said in June.

"Completing the refurbishment is something that we’re obviously excited about," he said, but noted some local residents are uneasy about the plan to remove the bridge. "We’ve had to reassure them that yes, it will come back."

Mysteries uncovered during bridge refurbishment

ST. MARYS, ONT. — Bridge refurbishment offers a unique opportunity for those involved to imagine what it would have been like to be in the shoes of the people who made them.

But sometimes the experience simply creates more mystery.

Andrew Ross, vice-president of B.M. Ross and Associates Limited, recalled how, during repairs to a 1932 concrete bridge in Huron County, he realized the original workers must have poured cement continuously to make the spandrel arches supporting the deck.

He knew that because there were no cold joints in the arches.

Yet how they could have poured such a volume of concrete without ready-mix trucks?

He’ll never know for sure — just as we’ll never know for sure the original colour of the Water Street Bridge in St. Marys.

1/2

Photo:

Recent Comments

comments for this post are closed