A slim, precast concrete paving slab design could soon cut the time required for road works in half, say scientists at a Singapore university.

While the new material mix is in the early stages, it could provide a boon for cities like Toronto which faces not just a $3.6-billion tab to repair and replace the aging Gardiner Expressway, but a major headache in dealing with the resulting traffic chaos during the multi-year project.

The material has already been manufactured and tested in the lab and is moving to the next stage of development with field trials through 2019 at the Nanyang Technological University (NTU) in Singapore where the NTU-JTC Industrial Infrastructure Innovation Centre (I³C) is located.

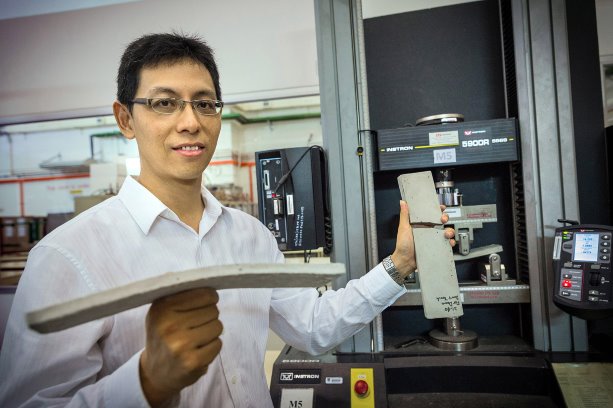

Yang En-Hua, the inventor of ConFlexPave, says the research suggests so far it is not only bendable but lighter, stronger and has a longer lifecycle than traditional concrete.

The goal is to make slimmer precast pavement slabs that can be quickly hoisted into place, cutting down lane or road closures and lessening gridlock. Also, the flexibility would be a major design plus for areas at risk of earthquakes, such as Japan. The mix isn’t that much of a change, Yang says, using ordinary portland cement, but there are more specific, harder materials and polymer microfibres used.

"The synthetic fibres, besides allowing the concrete to flex and bend under tension, also enhances skid resistance," says Yang. "The key breakthrough was understanding how the components of the materials interact with one another mechanically on a microscopic level."

As they develop the formulation further and expand their knowledge of how the components interact, they can better tailor the mix to attain their end goal of flexible, light but resilient concrete for pavement applications.

"The microfibres, which are thinner than the width of a human hair, distribute the load across the whole slab, giving a concrete tough as metal and at least twice as strong as conventional concrete under bending," Yang explains. "It is all designed to ensure synergistic interaction between the fibres and matrix through proper control of the interface between the two."

ConFlexPave has been successfully tested as tablet-sized slabs at NTU laboratories. It will be scaled up for further testing over the next three years in partnership with JTC at suitable locations within JTC’s industrial estates and in NTU where there will be human and vehicular traffic.

"This formula reduces the thickness and weight of precast pavement slabs, hence enabling speedy plug-and-play installation, where new concrete slabs prepared off-site can easily replace worn out ones," says NTU professor Chu Jian, interim co-director of the NTU-JTC I³C.

His colleague, Koh Chwee, director, technical services division of JTC and co-director of the NTU-JTC I³C, calls it "game-changing technology."

The group says it will reduce labour on site, increase safety and cut pollution from gridlocked traffic.

Yang says while ordinary portland cement is the binder, the concept can be applied to other binder systems as well, but there are no other enhancements such as CO2 injection or the addition of microbials during the normal mixing and curing process.

Whether ConFlexPave would be suitable for the Gardiner Expressway in Toronto is still a stretch, he says.

"Yes and no, it depends on what type of distress the bridge deck is facing," he says. "If it is just the surface distress and the substructure is still in good condition, then the precast thin paving slab may work."

The properties of ConFlexPave go beyond lighter weight and flexibility, it can change shape under pressure.

And, in the liquid pre-curing stage, it can be poured and molded into almost any configuration, which makes it ideal for pavement sections, Yang says.

His work with bendable concrete stretches back to his PhD studies at the University of Michigan where his faculty supervisor professor Victor Li pioneered the development of Engineered Cementitious Composites (ECC) in the early 2000s. That work was fruitful, creating better strain capacity using polymer fibres and drawing from research around Fibre-Reinforced Concrete.

"I was in the team when building up the ECC expansion joint in the Grove Street bridge in Ypsilanti, Mich., in 2005," he says. "The ultra-thin precast paving slab project I initiated here in Singapore is to use a newly formulated flexible concrete for slim precast pavement slabs. To satisfy the requirement of precast rigid pavement application, we add several new dimensions to the material as well as the slab design. The new formulation with hard particles enhances the skid resistance of the driving surface while the new surface texture reduces tire noise and enhances drainage capacity. We also adopt local materials for the new flexible concrete formulation."

Yang is building on proven technology: ECC research in Michigan reported bendable concrete is 500 times more resistant to cracking and requires less material.

For example, the one kilometre Mihara Bridge in Hokkaido was constructed in 2005 with a steel-reinforced road bed and 800 cubic metres of ECC. It required 40 per cent less material.

Recent Comments

comments for this post are closed