Ledcor is one of two companies that have won VRCA 2014 Silver Awards for their work on the University of British Columbia (UBC) Bioenergy Research and Demonstration Facility.

Ledcor won in the General Contractor up to $15 million category.

The UBC clean energy project is North America’s first commercial-scale biomass-fueled, cogeneration (heat and power) system.

It is designed to generate enough clean electricity to power 1,500 homes and to reduce the university’s natural gas consumption by up to 12 per cent.

The project required a high degree of co-operation between the builders, said Ledcor senior project manager Richard Aarestad

"During this project, a unique partnership between two general contractors – Ledcor as base building contractor and Nexterra (Systems Corp.) as the equipment installer – was formed," he said.

During the transition between the two phases of the project, Ledcor co-ordinated the delivery and installation of Nexterra equipment to the site and made sure the building was ready for handover.

"A tight site meant detailed scheduling was needed to manage the trades," Aarestad said.

"We communicated UBC’s, Nexterra’s and our expectations of working around the equipment during phase two of the project, to keep the trades safe and the integrity of the equipment intact."

The physical constraints of the site led Ledcor and Nexterra to develop a traffic management plan to co-ordinate deliveries that included designated trucking routes, access gates and detour routes.

"The main components of the project were manufactured by local suppliers delivered as needed, because of site constraints and the production limitations of local factories," Aarestad said.

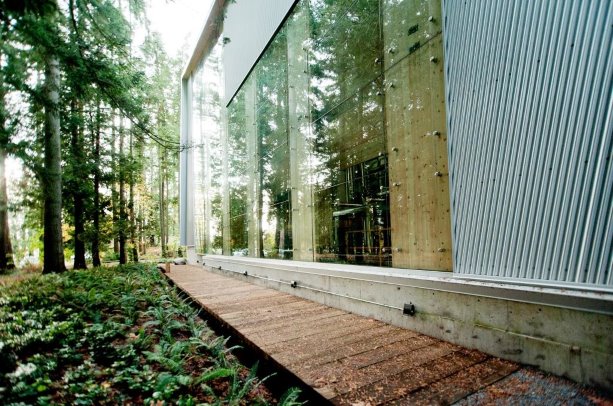

The three-storey wedge-shaped building has an area of 21,000 square feet.

In addition to the heat and power system, the building contains a control room, lab space and two fuel delivery bays.

The facility is nothing if not woodsy.

Set in a copse of trees just east of Marine Drive on the western edge of the UBC campus.

It is built mostly of cross-laminated timber (CLT) and glued laminated timber (glulam).

CLT is a wood-based structural system that demonstrates low environmental impact and B.C.-based building technologies.

It is promoted as a replacement for steel or concrete in multi-storey residential and commercial buildings.

Glulam is made of glued laminated timber bound together with an adhesive.

This forms a single structural piece that is stronger and more environmentally friendly than solid timber.

The building, which is the first commercial application of CLT in North America, has earned LEED Gold certification.

"The facility’s key sustainably feature is the CLT panels, which are made of pine beetle-killed wood," Aarestad said.

"The panels have a low carbon and low environmental impact. They are locally sourced and are a B.C.-based technology."

CLT panels were used for all load bearing walls and most non-load bearing partitions, suspended floor and roof decks.

At the time of construction, the facility was the largest CLT building in Canada.

Glulam columns connected to glulam beams with steel box connectors formed moment frames with wide clear spans, which were necessary to make room for the installation of the Nexterra equipment.

Aarestad said many lessons were learned about the use of CLT panels on the project.

This included developing fire-stopping details for CLT walls and slabs.

Other related challenges were addressing CLT production tolerances to cast-in-place concrete tolerances, and reconciling production and installation requirements in a very tight site.

There were no lost time accidents for Ledcor on the project.

"We developed detailed procedures to safely install and work with CLT and manage their handling, hoisting and erection," said Aarestad.

"The roof panels had self-adhered membranes pre-installed in the factory, which required that we put in place work procedures to address access on the sloped roof during wet and snowy weather."

The UBC Bioenergy Research and Demonstration Facility has two operating modes.

The first and commercial mode will use Nexterra gasification technology to convert waste wood into a clean synthesis gas ("syngas") that can be used to heat the campus.

The second, demonstration heat-and-power mode, will use Nexterra syngas conditioning technology and a gas engine to convert syngas into electrical power for use at the university.

The project owner is The University of British Columbia, represented by Infrastructure Development – Project Services.

Construction cost $8.5 million and was completed between September 2010 and June 2012.

The other VRCA Silver Award of Excellence winner for work on the project is Jeda Mechanical Ltd., which won in the Mechanical Contractor up to $3 million category.

1/2

University of British Columbia

Recent Comments

comments for this post are closed