Imagine a robotic machine that builds an entire house out of concrete. If it sounds futuristic, then the future is here, courtesy of University of Southern California engineering professor Behrokh Khoshnevis and his Contour Crafting Robotic Construction System.

Khoshnevis started investigating the possibility of such a machine in 1995, when he was working on 3D printing.

"I was trying to make the process faster and there is really no other way than increasing the thickness of the layers," he explained, referring to the basic methodology 3D-printing technology uses: layer-by-layer fabrication.

When Khoshnevis came up with his Contour Crafter, which in its most basic sense consists of a computer and a corresponding 3D-printer robot, he thought it could be used to build industrial parts, including walls for ship and submarine pillars.

"It was only around 2004 that I thought about using this technology for building construction," he said, adding he tried different materials with the Contour Crafter including spackling paste, gypsum and concrete.

"Any cementitious product can be used," he said.

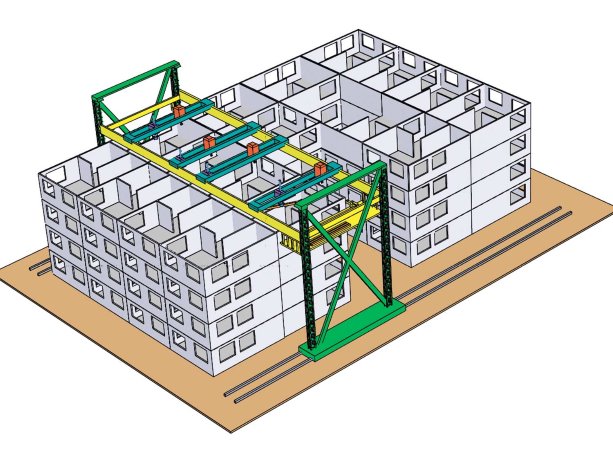

A typical Contour Crafter features a robot resembling a swing-set frame.

It’s slightly wider than the particular building under construction.

This robot moves forward-to-backward and vice versa along a track, over the area where the structure is to be built.

A nozzle is suspended from the swing-set frame.

It moves back-and-forth along the top of the frame, secreting concrete as it goes.

Khoshnevis likens the process of Contour Crafting to decorating a cake.

"You use layer after layer of paste material in order to build a certain geometry. The computer, which has the architectural design in it, drives the robot and moves the nozzle along the walls, building it layer-by-layer," he explained.

One problem Khoshnevis discovered early on is that printing in thick layers involves a loss of surface quality.

To solve this issue, the Contour Crafter has a trowel on the end of the nozzle that smoothens the concrete as it’s laid down.

The machine comes in various models, some larger, some smaller, and even one with multiple nozzles.

While Khoshnevis admitted that he hasn’t printed an entire house yet, due to space limitations in his lab, he has printed large test pieces, such as walls.

He highlighted one concrete wall the machine built that was mixed with composite fibers.

It had a strength of 10,000 psi compared to an average concrete structures that come in at 3,000 psi, he added.

He said the advantages of Contour Crafting over traditional construction methods are many.

"You can build houses, parts of houses, whole houses and pre-fabs," he said, adding the speed of fabrication is much greater than a house built using human labour. For example, Khoshnevis estimates the Contour Crafter could construct a 2500 sq. ft. home in about 20 hours.

Furthermore, he said, Contour Crafting offers a superior surface finish and that related infrastructure, including plumbing and electrical features, could be installed while the building is being erected.

"Rather than using continuous rebar, you can use segments of rebar automatically inserted and assembled inside the building," he said.

The machine can create curved, domed and straight walls.

"You can execute very exotic, beautiful architectural features without incurring additional cost," Khoshnevis added.

Other advantages of Contour Crafting, according to Khoshnevis, include lower construction costs on account of reduced labour needs, minimal energy use and improved work-site safety.

"There’s a lot of concern about people being put out of construction jobs. The reality is that a lot of new jobs can be created in this sector as well," he asserted, noting his technology could create opportunities for women and the elderly.

Currently, Khoshnevis is raising funds to commercialize the Contour Crafter

He hopes to have a commercial machine for smaller houses available in about a year.

Khoshnevis said international developers have already approached him, expressing interest.

NASA is also working with Khoshnevis’s research team at the University of Southern California to explore how the technology could be applied to creating structures for space missions.

1/2

The Contour Crafting Robotic Construction System (above) can 3D print concrete.

Photo: Courtesy Behrokh Khoshnevis

2/2

A rendering shows how a structure could be built with the machine.

Photo: Courtesy Behrokh Khoshnevis"

Recent Comments

comments for this post are closed