Embodied carbon is recognized as a major, if not the dominant, CO2 component linked to a building throughout its life. However, without the right tools, accurately assessing the embodied carbon in a project at its design stage is often hard to pin down.

As Anna Beckett, associate director at British engineering consultancy Buro Happold, writes, “For all the measuring of carbon that we’re doing, it’s remarkably hard to find a set of values that gives an up-to-date picture.”

Engineering software companies are making progress towards helping project designers better understand the embodied carbon implications of their material options.

For example, Autodesk’s cloud-based 3D modelling software called Fusion now has an add-on called MSI (Manufacturing Sustainability Insights).

“With a few simple clicks,” users can now calculate the carbon emissions of their designs in real-time and identify alternatives to reduce the product’s carbon footprint, the company says, all backed by the latest climate science and the most granular, transparent data available.

Similar ambitions are being undertaken by global design and consulting firm Gensler. It intends to use the company’s past project data base totalling billions of square feet to develop several digital tools.

One is a set of performance standards that informs analytical design called the Gensler Product Sustainability (GPS) standards.

“Our Product Sustainability Standards are a series of publicly-available, minimum performance requirements that we’re signalling to the construction industry as being what we are going to be implementing on our projects,” Philip Galway-Witham, Gensler’s northeast regional resilience leader, told the Daily Commercial News.

He explained this “common materials framework” provides simplified and clear language for performance criteria among the hundreds of different performance indicators available for materials and finishes in the construction industry.

“The intent is to move the supply chain in the construction industry forward in North America and Europe, and to encourage suppliers to incrementally improve their own supply chains and the materials that are going into projects.”

He said this will help to prioritize and demand the production and selection of healthier, lower-carbon, more sustainable materials in the built environment.

Version One of the firm’s GPS standards was announced January 2024. Version Two is scheduled to go live in June 2025, and will include sustainability criteria for wallcoverings, textiles, gypsum, hollow metal doors and frames, insulated wall cladding, access flooring, broadloom carpet, and tile.

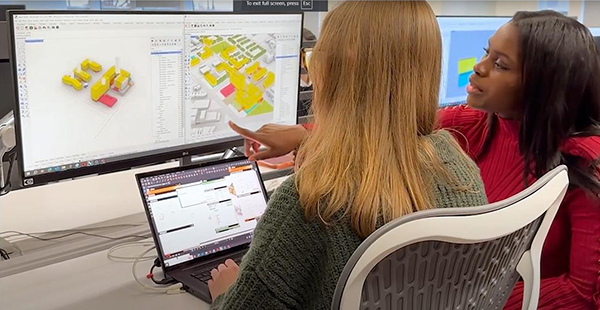

On a more client-direct basis, Gensler is introducing an AI-assisted digital design tool called gBlox.CO2.

This is a plug-in to Gensler’s design software which allows their designers to get a quick, iterative sense of the carbon impact of their choices at the very beginning of large architectural projects.

To explain, Galway-Witham offered the example of Gensler designers being able to analyze the relative impact of a project with two towers and one podium versus three podiums and one tower.

“What this tool does, through standard design option processes, is analyze inputs in terms of assumptions of structure, pulls from existing benchmark data from CBECS and other third party industry standards, and pulls in benchmarking from our huge portfolio of work.”

“That sort of master planning level is really important,” he continued. “We found that equipping our designers with the capacity to get a rough sense, a rough order of magnitude of what the carbon impact might be that early on can help set the direction of that project through its life. We can get a sense of what are the pros and cons of a given scheme to then set that direction early on and that becomes an initial target that then gets refined during the design process. We’re still designing our buildings, but it’s about leveraging these data sets.”

Gensler’s digital and AI-assisted design tools don’t end there. Galway-Witham spoke of dedicated specialists who conduct daylighting studies and critical life cycle analyses to account for the embodied carbon of a project.

“Even before a project starts, we will have early sessions, visioning and strategic kickoffs with clients using these tools to establish the goals for the project.”

John Bleasby is a freelance writer. Send comments and Inside Innovation column ideas to editor@dailycommercialnews.com.

Recent Comments