Concrete has been used as a building material since 6500BC. Throughout this time, it has been seen solely as a structural material. Today, 14 billion m3 of concrete is poured annually.

Recently, considerable efforts have been made to modify concrete formulations in order to reduce the associated emissions and to even embed carbons into building structures.

However, innovative new approaches are being taken for the use of concrete that go beyond merely creating today’s building projects.

In Cambridge, Mass., the MIT Electron-Conducting Carbon-Cement-Based Materials Hub (ec3 hub) and the MIT Concrete Sustainability Hub (CSHub) have partnered to investigate multifunctional uses for concrete. Significant progress has been made that might, in future years, result in concrete being seen from an entirely new and more environmentally positive viewpoint.

One possibility is to use concrete as an energy storage system.

MIT hub researchers have approached this idea from the perspective that the world is beginning to transition towards renewable energy sources such as solar and wind. Yet, these sources are intermittent.

“To address these concerns, large-scale energy storage solutions that allow for excess energy produced during peak times to be stored and released when needed, are critically required,” they write.

However, large-scale battery storage technology relies on mined minerals such as nickel, lithium and cobalt. Their extraction has environmental impacts of their own.

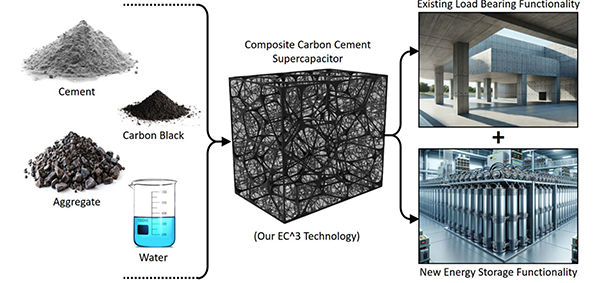

The MIT hubs believe blending the inexpensive and globally abundant raw materials of hydrophobic nanocarbon black (nCB) with binders such as Portland cement, aggregates and water can create electron-conducting carbon concrete. They call it EC^3 technology.

Advancements in EC^3 technology have, in turn, led to the development of a 12-volt EC^3 supercapacitor, the researchers write. At this point in its development, the supercapacitor can power small electronic devices such as LEDs, game consoles and cellphone chargers.

What this could mean in the future is that concrete foundations could have a dual purpose as energy storage for that building without taking up any extra space. The same principle could be scaled down and be applied to houses and apartment buildings.

“Recent developments have improved the material’s resistance to energy leakage,” researchers write. “The EC^3 technology presents considerable opportunities for mass scaling. For example, it is estimated that approximately 33 cubic metres of EC^3 could supply the average daily energy demands of a residential house (~10 kilowatt hours).”

What adds further promise is that the capacitance of EC^3 cells remain largely unaffected by aging. This confirms the stability of the nCB network over time and therefore the long-term energy storage capacity of the cement-carbon composites.

“One of the most promising applications of EC^3 is storing intermittent energy from renewable sources such as wind, solar and tidal power,” the researchers write. “By integrating energy storage capabilities into the structural components of wind turbines and tidal power stations, the EC^3 technology could help stabilize and enhance the reliability of the energy grid.”

The growth of 3D printing for homes and commercial buildings also opens new possibilities. The entire structure could be used as an energy storage device for the power generated by, for example, rooftop solar panels.

“It is possible to fabricate bespoke structures that incorporate EC^3 technology in a wide range of application-specific and fully customizable form factors.”

Taken even further, the EC^3 technology could be used to build self-charging roads for electric vehicles.

“These roads could potentially harness and store energy and be used to wirelessly charge vehicles as they drive along them, reducing the need for external charging stations.”

In conclusion, the MIT hub researchers suggest a very bright future for concrete in tomorrow’s world, one that transcends the negativity surrounding the material’s environmental impact today.

“EC^3 technology leverages innovative material science to bridge the gap between structural support and energy storage, offering a potential solution for the future of construction and energy management. Through continued research and collaboration, EC^3 has the potential to create shifts in the construction industry, contributing to a more resilient, sustainable built environment.”

John Bleasby is a freelance writer. Send comments and Inside Innovation column ideas to editor@dailycommercialnews.com.

Recent Comments