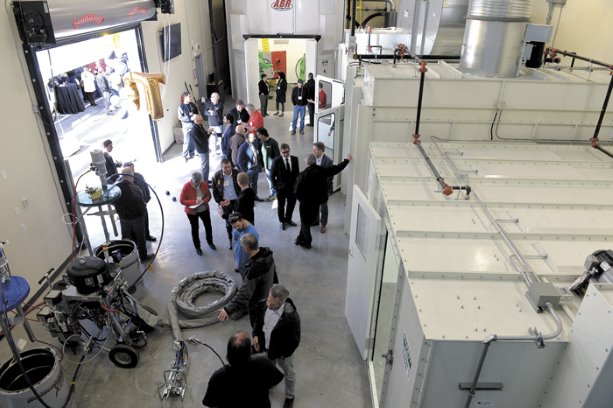

The new 14,000-square-foot addition to the Finishing Trades Institute of B.C. (FTI), which now has 40,000 square feet of training space for tradespersons, will provide space for two growing training needs.

"Primarily, we saw a lot of work for industrial painting in the future and we had outgrown the facility we were in," said Patrick Byrne, FTI director of training.

"There was also newer technology and equipment emerging."

Industrial painters deal with range of large industrial structures. "These are the guys you see hanging off a bridge," said Byrne. They area also the individuals who paint fuel tanks, apply linings for penstocks on dams, work on pipeline or, in confined spaces. Industrial painting is a component of becoming a Red Seal painter.

The other need was a greater space for a mock-up area and office for the two-year-old hazardous material training program where workers learn to identify and deal with harmful materials such as asbestos, lead, contaminated soils and moulds.

The $4-million expansion at the Surrey campus was funded entirely by District Council 38 of the International Union of Painters and Allied Trades which represents more than 2,000 B.C. men and women such as painters, glaziers, wall and ceiling installers, lathers and drywall finishers, hazardous materials abatement specialists, and water blasters. They are the trades that FTI offers courses in.

The FTI’s can accommodate 350 apprentices a year – the average class size is 16 – but enrolment is approximately 250, according to Byrne. While the FTI is backed by the union, its enrolment is split 50-50 between union and non-union members. The institute can run six classes simultaneously, has six full-time instructors and four part-time instructors.

The added space has allowed the facility to build an on-site $180,000 abrasive blast tank, similar to petroleum storage tanks seen at refineries.

"It is a one-of-a-kind tank for sand blasting," he said, the only facility of its kind in Canada.

The tank is a smaller version of what is seen in industry, it can provide apprentices with the experience of working inside an enclosed tank. The facility is equipped with CCTV cameras so that instructors can monitor students at all times, he said.

The addition has also allowed the institute to update the equipment that apprentice industrial painters will train on. The FTI now has a new $200,000 spray booth, plus a $70,000 pleural component pump, a sprayer that takes three apprentices to operate it.

"This is an expensive piece of equipment and normally an apprentice would not get the opportunity to operate it (on a job site)," he said.

The unit is fed by two 45-gallon drums of paint and catalyst which is directs to a spray gun. The paint has the ability to dry in 30 seconds, so proficiency in application is needed. Operators also need to be able to clear the sprayer and line immediately after finishing a job.

"We now have the opportunity to offer hands on training," he said.

Don Whyte, executive director of the Hazardous Material Association of B.C., said the expansion provides the ability to offer association courses in hazardous material handling for those working in the construction industry. The mock-up area provides workers with a more realistic experience.

The program is the only one of its kind in B.C. and provides pre-employment training for individuals who may be at risk when deconstructing buildings or on sites where hazardous materials may be encountered, Whyte said. The FTI training is followed by pairing individuals with an experienced individual on the job-site.

"Right now, there is no provincially-recognized training program," he said.

"We are getting close and we have lobbied WorkSafeBC to adopt our program," he said.

There is also no requirement by municipalities that deconstruction crews working on a site or the contractor have any kind of hazmat training.

Normally, he said, a consultant would go into a facility to detail the various types of hazardous material that removal crews might deal with. Whyte said there are some excellent consulting companies in the field today and some that are less competent. As a result, it is to the worker’s advantage to be able to identify potential risks and protect against any risk that may not be cited in the original consultant’s report.

Whyte said the City of Vancouver is the most progressive in terms of setting down standards for contractors to carrying out the deconstruction and extraction of hazmat material in buildings undergoing demolition, but also neighbors to mitigate impact.

"If every municipality adopted their standards, the province would be better off," he said.

FTI started in 1992 as an institute where painting apprentices could receive the instruction needed to move toward journeyman status. FTI moved to its current Surrey site into an old building, utilizing half the structure, eventually the whole structure. In 2005, it did a renovation to the structure and added a new glazing department. FTI is one of two places in B.C. that offers glazing courses for apprentices. A year later, wall and ceiling finishing courses were added, then drywall finishing and lastly the hazmat course. As the need has grown, FTI has acquired neighboring properties. The facility now also provides a place for journeymen in the various trades can obtain upgrading, including safety certificate renewals.

The institute continues to fill roles in the community working with partners. It has worked with Park and Derochie (Seaside) Coatings Inc., one of the largest industrial painting contractors, which has been able to identify former citizens of Syria who had worked previously in the industry and help with their integration into the construction industry. It also works with First Nations group either supplementing their own training programs or providing a place where First Nations people can obtain pre-employment training such as with the hazmat program.

The program’s focus is on ensuring that those coming through the programs have skills needed to respond to the changing industry needs. Byrne said one of the challenges the institute is looking at is how to help union contractors stay productive, competitive and expand their business. He would like to be able to offer business administration, entrepreneurship, and financial accounting courses.

"We want to grow our contractors," he said.

Productivity in training at the institute is highly stressed, said Byrne. Instructors stress working safely, punctuality, limiting cell phone use, and not prolonging work breaks. He said the focus is also on developing skills and performing high-quality work.

"The less call-backs and deficiencies, the more efficient the contractor," he said.

Recent Comments

comments for this post are closed