BIM is helping project planners visualize their creations before they are built.

Beyond predictive operational insights, BIM can also provide guidance directed towards the 3R concept of “Reduce, Recycle, Repurpose” concerning the use of materials, leading ultimately to a circular material economy that reduces CO2 emissions.

“Think of a world where every project is designed with its lifecycle in mind, where buildings are not just constructed and demolished, but born and reborn in various forms,” writes Dr. Jimmy Abualdenien, head of digital twin product at the Nemetschek Group. “This isn’t a distant dream but a present reality, thanks to visualization technologies that make sustainability not just achievable but tangible.”

It’s a wonderful idea but developing a Construction Demolition Waste (CDW) management strategy is a challenge.

A study published in April 2024 by Swiss-based non-profit MDPI explains how BIM can provide credible pathways forward.

“Based on BIM-based CDW data calculation, the quantity information of materials can be accurately, quickly, and systematically extracted from the BIM model and combined with waste indicators, thus solving the problems of complexity and inaccuracy in quantification in building and construction waste management.”

The authors considered three different approaches to CDW management.

The first was what they called “the traditional CDW management method,” or linear approach that recycles mostly metals. It had a minimal impact on landfill waste.

The second focussed on the 3R strategy. High-value materials like metals and glass are reused for sale, concrete, cement and bricks are recycled, timber and plastics are incinerated to recover energy, and the remainder sent to landfills.

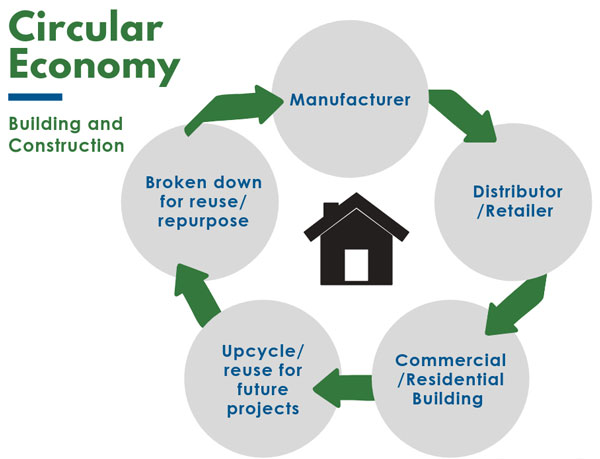

The third scenario considers the circular economy strategy. It offers the most promise for the future, the authors say, and would be the most effective process for mitigating carbon emissions.

“Different from the traditional linear economy of the past, the circular economy offers a new view of today’s products as tomorrow’s resources to create a virtual cycle in a world of limited resources,” the authors say.

“This scenario prioritizes reuse over recycling, and thereby offers the lowest energy use. It focuses on recirculation of metals, plastics, glass, and wood, generates recycled aggregate from concrete and cement, recycles bricks and tiles, and uses the remaining waste for energy recovery. This approach preserves materials and products over the longest period. At the end of the product’s life cycle, the upgrade of recycled materials is carried out, which can be used repeatedly as a secondary resource.”

Analytical tools are being developed to help achieve the ultimate objectives of waste reduction, material circularity and CO2 reduction.

“What if we could predict the waste we expect to generate and understand what waste management should cost?” asks Chris Clarke, director of performance and improvement at the U.K.-based not-for-profit organization SCAPE.

SCAPE has created a “digital, flexible and scalable” database called the Construction Waste Portal that uses the 3R principles to help builders calculate construction waste before shovels hit the ground.

By crowd-sourcing and analyzing waste management data from over 1,500 completed construction projects, Clarke says SCAPE’s portal “offers precise forecasts for waste generation and embodied carbon,” complete with “should-cost” predictions for waste management planning using live market data. Scape claims their most recent frameworks consistently delivers recycling rates above 95 per cent.

On a larger and longer-term scale, the concept of Material Passports for the storage and maintenance of material records has been discussed for several years.

In November 2023, engineering and environmental consultancy Waterman Group presented its Material Framework Passport, what it claimed as the “first standardized approach” to documenting and managing materials throughout their lifecycle.

“The framework aims to provide a roadmap to create a database of information, containing the identity, specifications and performance data for materials, products and building elements. The data in Material Passports will facilitate informed decision-making on efficient material reuse.”

Although many questions remain concerning the massive requirements for the storage, maintenance and access of such material records, it is anticipated that Digital Product Passports will become mandatory through future EU legislation.

John Bleasby is a freelance writer. Send comments and Inside Innovation column ideas to editor@dailycommercialnews.com.

Recent Comments