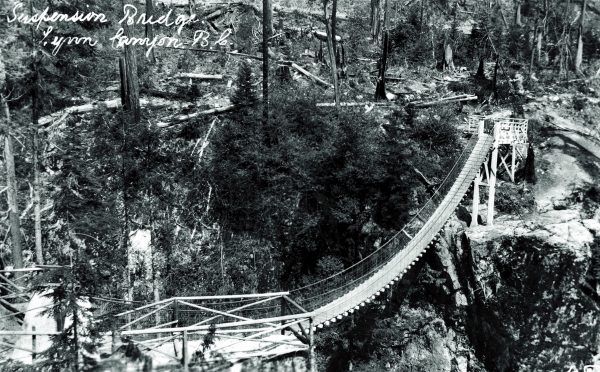

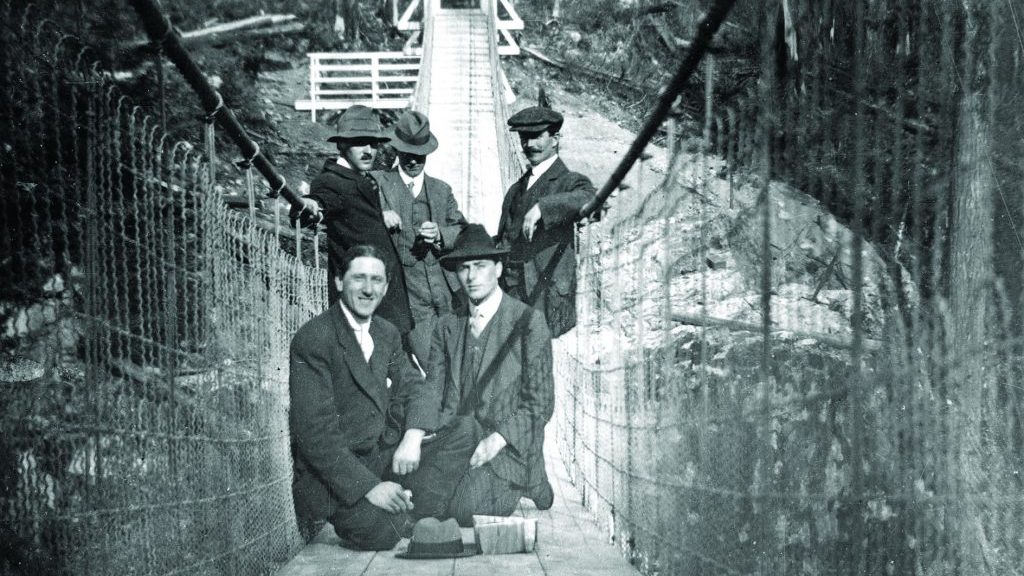

The Lynn Canyon Suspension Bridge has supported pedestrians since 1912 when Lynn Canyon Park opened.

While the massive concrete blocks on either side of the canyon have anchored the bridge’s suspension cables for more than a century, engineers at the District of North Vancouver are constructing an auxiliary wire rope system designed as a backup.

The bridge crosses the canyon at about 50 metres up, with the vigorous Lynn Creek roiling below. It’s sometimes referred to as “the poor man’s Capilano suspension bridge,” because Lynn Canyon visitors use the bridge for free, while tourists pay to cross its privately-owned counterpart.

“It’s a little steeper and livelier than the Capilano,” says Brian Counihan, senior project engineer at the District of North Vancouver. “And with more than a million pedestrians crossing here annually, there’s a lot of wear on the bits and pieces that make up the bridge.”

The wooden deck of the bridge is typically replaced every 10 years, while the steel suspension cables were last replaced in the 1980s.

“We had a good look at the existing cables in 2015 and the engineering team hired a testing company to examine them,” says Counihan. “The report said the cables were fine, but there were some unknowns where the cables tie into the foundations that should be investigated.”

Counihan sourced as-built historical drawings from the original construction plans. The sketch showed that the builders had cut into the rock on either side and poured two concrete foundations.

“Inside each foundation block, they buried a railway rail,” he says. “The cables had been fixed to two steel straps placed around each rail, which protruded in a loop from each block. However, we had no way of inspecting the integrity of those steel straps encased inside the blocks without drilling into the concrete. While the risk was low, we knew that if one of the steel straps were to let go, you would lose one of the cables, which would be catastrophic for the bridge.”

Rather than replace the steel loops or foundation, Counihan’s team chose to create a secondary support system for the cables as a backup. The system would use a new wire rope fixed to rock anchors located two to three metres behind the original concrete foundation blocks.

Online Constructors Ltd. of Abbotsford, B.C. was selected as the general contractor for the project, which was budgeted at $175,000, including design. The anchoring system was devised by CM Rock Engineering Ltd. of Vancouver around 46 millimetre DYWIDAG anchors with double corrosion protection.

Lynn Canyon Suspension Bridge project, which was budgeted at $175,000, including design. The anchoring system was devised by CM Rock Engineering Ltd. of Vancouver around 46 millimetre DYWIDAG anchors with double corrosion protection.

Work began in May with diagonal holes drilled into solid rock just below the surface to a distance of about eight metres.

“When we removed the overburden to begin drilling we found some of the original pins that must have been used to provide temporary bracing when the bridge was first built,” says Counihan. “They must have hammered them into the rock manually.”

The four new anchors have already been placed and the holes have been grouted. New concrete-and-steel rebar anchor blocks are being constructed on either side of the canyon to encapsulate the anchors.

The new anchoring system couldn’t disturb either the existing concrete foundation or trees in the vicinity.

“The trees have grown tall since the historic photos of the bridge construction were taken,” says Counihan. “This meant we had to encapsulate tree roots into the new concrete anchor blocks, protecting them with a white foam product.”

Once construction is complete, the new wire ropes will be fixed to new anchor plates attached to the foundation blocks on one end and to the existing steel suspension cables on the other. The wire ropes won’t be required to carry a load, however, unless the original suspension cables fail.

“We don’t expect that the existing steel cables will let go, but if that ever happened, the new wire rope system would keep the bridge suspended,” says Counihan. “We hope it performs for another hundred years.”

Recent Comments