The $6.8 billion Woodfibre LNG project has given the green light to a China fabrication plant to start construction on 19 modules that will make up the football field-sized liquefied natural gas plant, to be located on the west side of Howe Sound, just southwest of Squamish, B.C.

The modules fabrication marched in step with FortisBC announcing that construction for the Eagle Mountain-Woodfibre Gas Pipeline will begin on or after Aug. 28. Feedstock for the LNG is from Pacific Canbriam in the Montney zone in northeastern B.C.

In September, construction crews will begin readying the site for the plant installation with 50 to 60 workers onsite rising to a peak workforce of 800.

McDermott, an international construction services company operating in 54 countries, is providing the engineering, procurement, fabrication and construction lead while Ledcor/Bird is acting as the construction sub-contractor for the project, which is slated to be operational by 2027.

The large construction project is being covered by Singapore-based Pacific Energy (part of the Royal Golden Eagle Group) funding 70 per cent of the cost with Alberta-based Enbridge assuming 30 per cent. The plant is a smaller project compared to LNG Canada in Kitimat, which is projected to have a finishing line cost of $40 billion.

Ramping up for a major new Woodfibre facility has involved the deconstruction of the site’s l00-year-old pulp mill, the engine behind a 212-acre town site of 750 individuals. The town site closed in 1973 and the pulp mill in 2006, leaving an out-dated facility, waste residuals and some 300 creosote poles that the new LNG plant owners had to clean up.

“It is pretty dramatic what we have done on the site,” said Woodfibre’s communications director Sean Beardow, adding the pulp mill is now completely removed and site remediation work has been undertaken.

The modules

The 19 dedicated modules are being fabricated in Qingdao City, China at the Qingdao McDermott Wuchuan (QMW) steelyards. QMW is a joint venture between McDermott and the China State Shipbuilding Corporation.

“The largest module is the liquefaction unit,” said Beardow, adding it is the “heart of the facility” and weights close to 11,000 metric tonnes.

Each module will be pre-commissioned and will have all piping, steelwork, equipment, electrical and instrumentation completed before shipping, with final commissioning occurring once they are joined at the Squamish site.

“We expect that the first module will be ready to be shipped in late August 2024,” said Beardow.

Work starting in September will be moving towards receiving the start of the flow of modules.

“Fabrication will be ongoing for the next couple of years.”

The modules will be moved from the plant to ships using self propelled multi-wheeled transport (SPMT) units. These units are platform heavy haulers with a large array of wheels with computer controlled axles that enable the units to turn. They can be linked and a power pack can be used to drive the train. The SPMT’s lift the modules slightly to provide ground clearance and then roll directly onto heavy-lift transport vessels for oceanic transport.

“We want to show how we can construct the project and how to develop LNG economically with the lowest possible impact,” said Beardow.

The major design feature in the plant will see it using Siemens electric e-drive engines for compressing the natural gas.

“The biggest single thing in that profile is the use of the electricity rather than natural gas,” he said, which leads to a 90 per cent carbon reduction in emissions. The majority of LNG plants utilize natural gas as it comes in as a feedstock.

“Woodfibre LNG will be the world’s first net-zero facility when it begins operations in 2027,” he said.

When the facility is fully operative, it will produce 2.1 million tonnes of LNG per year compared to LNG Canada which is 85 per cent complete and will produce 14 million tonnes a year starting in 2025. If LNG Canada approves a second phase, now being considered, it will double capacity to 28 million tonnes.

The Floatel

Woodfibre LNG will house its workers in a floatel, a former cruise ship having 400 to 600 beds after concerns were raised that the large influx of workers would overwhelm the housing capacity of nearby Squamish.

The contractor for the vessel’s retrofit will announced later this year, Beardow said.

The floatel will have an on-board kitchen, recreational areas, sewage collection and holding tanks, garbage collection and a loading dock. BC Hydro will supply power via the Woodfibre site.

Beardow said some of the construction activities prior to the arrival of modules includes site clearing and grubbing, floatel and marine pile installations, preparation of berthing dolphins for the hook up of the floatel and preparation of the first module’s foundation.

Pipeline construction

The Eagle Mountain-Woodfibre Gas Pipeline project will expand the existing FortisBC natural gas pipeline that runs between Coquitlam and Woodfibre, near Squamish.

The project involves adding 50 kilometres of new gas pipeline between Coquitlam and Squamish. This includes 47 kilometres of new 24-inch gas pipeline from north of Coquitlam to the Woodfibre LNG site, and an additional three kilometres of pipe near Westwood Plateau in north Coquitlam.

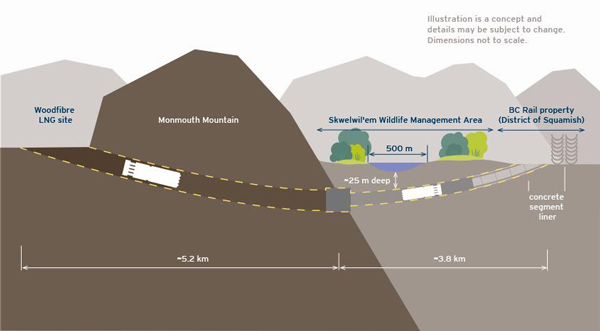

According to FortisBC, to access the Woodfibre LNG site, a segment of the proposed expanded gas pipeline section will need to run underneath the 673-hectare Skwelwil’em Squamish Estuary Wildlife Management Area (WMA). FortisBC has had an existing pipeline beneath the WMA since 1991 without incident.

FortisBC will build an underground tunnel 25 metres below the estuary waterbed and the new section of pipe will be installed within the tunnel. The tunnel construction will continue through the Monmouth Ridge Mountain and exit at the Woodfibre LNG site.

Recent Comments