Available for almost three years, transparent concrete panels have yet to shed their light within the Canadian construction industry.

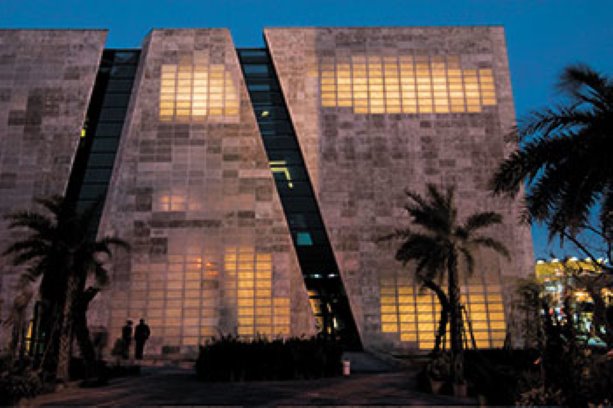

Spending more than 3,000 hours over two years to develop it, Italian company Essroc Italcementi Group unveiled their trademarked i.light concrete in 2010 at the Shanghai World Expo, using the panels to build the Italian Pavilion.

“The concrete is a proprietary product that uses a special mix of cement and chemicals that hold the resins together,” said Christopher Eagon, the Ohio-based marketing manager for Essroc Italcementi’s North American offices.

While the concrete has the same properties (strength, resistance to cracking), the polymer-based resins allow light to be transmitted through the building, Eagon said.

The panel exteriors are polished.

“They become very smooth, like glass,” Eagon said.

In Shanghai, almost 3,800 transparent panels (each weighing about 50 kilograms and measuring 50 mm thick, 1,000 mm long and 500 mm wide), made from 189 tons of transparent concrete, were used.

The panels covered about 40 per cent of the Pavilion.

Transparent concrete made its North American debut in October 2011 in Toronto at the annual Greenbuild tradeshow.

The European-made panels were shipped specifically for the show.

“It was an attention-grabber,” said Richard McGrath, director for codes and standards with the Cement Association of Canada.

“It’s not something you see everyday.”

He compared the panels to very large patio stones.

“They’re made with a very clear resin cast in concrete in a kind of honeycomb lattice,” he said from Ottawa.

Still, almost 1.5 years since their North American unveiling, no orders for the product have been placed in Canada or the U.S., Eagon said.

Essroc Italcementi is looking for North American partners, who would produce the patented product.

Like any new technique or product, engineers, architects and builders need time to get acclimated to the rather revolutionary cement panels, he said.

The economic downturn and resulting cost pressures likely also played a role in the product’s absence in North America.

Taking a tried and true approach, a lot of builders are working with traditional building materials at the moment, Eagon said.

While the cost of North American-produced transparent concrete hasn’t been nailed down, a fairly accurate estimate is it will cost about $2,700 per square metre.

Despite the material’s complexity, this concrete can be poured straight into forms at the building site.

The concrete construction panels, which transmit both natural and artificial light, are guaranteed to last as long as a panel made from traditional concrete.

Transparency doesn’t change over time because the resins have been treated to protect against ultraviolet rays.

The panels create ever-changing light and shadow effects throughout the day. The transparent effect is more evident when it’s dark and seen from the outside.

During the day, exterior light filters in, meaning potential energy savings because of less electricity use. Eagon envisions transparent concrete being used in buildings where experimentation or being on the cutting edge are relevant, such as university structures, art galleries and government buildings.

And, for projects where security is a concern, transparent concrete could be a viable consideration, McGrath said.

The panels are versatile.

The resins’ colour can be changed as can the shape and panel dimensions.

The panels can also be used in various applications: roof coverings, walls, floors, decorative, terraces, stairs and balconies.

The panels have a B2 Class (European) fire rating.

i.light was picked as one of Popular Science’s “The 100 Best Innovations of 2010.”

Recent Comments

comments for this post are closed