An Edmonton-based firm is proposing to build a full sized prototype of a high-speed transportation system, which involves a vehicle powered by a linear motor that levitates a few inches above a magnetic track.

“The way things are set up is we are delivering a demonstration project as a consortium,” said Dan Corns, founder and president of Magnovate Technologies.

“Once the demonstration is complete and we get safety approval from the Transportation Safety Board (TSB), then we can start deploying the system in Canada and worldwide.”

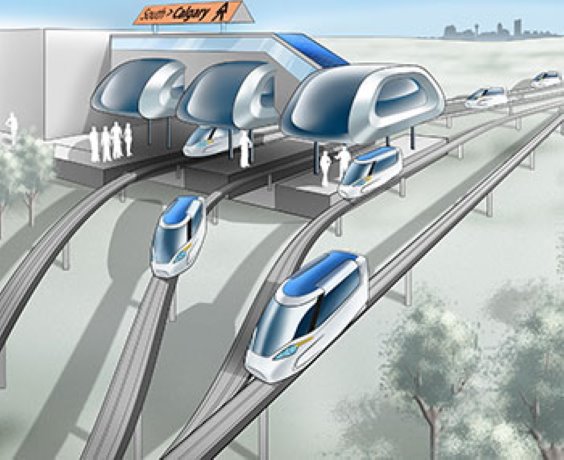

The company is developing a high speed transit system called Magline Transit, which is based on magnetic levitation (Maglev) technology.

Maglev uses magnetic levitation to create both lift and thrust to propel vehicles on a guide way.

In sharp contrast, conventional trains use wheels, axles and bearings that rely on traction and friction.

As a result, Maglev systems can routinely reach higher speeds than conventional rail or wheeled transport systems.

“The Maglev technology that currently exists is first generation,” said Corns.

“They built these systems and did not make any provision for switching technology, which is what allows the construction of a network. Our engineers start with the goal of creating a networkable system, which is based on a concept that is analogous to the internet.”

Corns said Magnovate engineers have developed high speed passive switching (HSPS) technology that allows the construction of a high speed transportation network.

Using computing terminology, he explained that the Maglev tracks are part of the power system, so vehicles can travel by themselves or in a group like a “data packet”.

All vehicles are automated and can go anywhere within the network.

Traffic can flow constantly because there is no stopping and switching takes place offline, without the need for mechanical parts or physical switches.

“We have already created prototypes that prove the passive switch and advanced levitation technology,” said Corns. “At this stage, we need to build a scale demonstration track that can be elevated at working scale with real vehicles, in which people can ride. This will allow us to prove the feasibility of the passive switching technology at this scale.”

According to Corns, Magline Transit system would be developed first in urban local area networks (LANs) with trains travelling at about 150 km per hour.

The local networks will be connected to high-speed wide area networks (WANs), where trains would travel at 500 km per hour.

Currently, Magnovate is trying to secure funding to build three full-sized vehicles, a small section of test track to be built in San Jose, Calif., and then a one-kilometre section of track built on University of Alberta land.

Stantec is working on a track design and the general contractor will be PCL Construction.

The project is scheduled to start in early 2014 and both firms are making in kind contributions to allow more capital to be invested in the development of the technology.

The total cost of the prototype is expected to be about $15 million.

Another project is being developed to build local Magline Transit systems on the campuses of the University of Calgary, Red Deer College and U of Alberta.

These systems would grow into wider networks and eventually link Edmonton and Calgary with a 300 km section of high speed transit line.

The proposed line has the potential to reduce the travel time between Edmonton and Calgary to 45 minutes, compared to about three hours by road.

The estimated construction cost of the project is US$3.60 billion.

Magnovate was founded in 2012 and has already raised $2 million from Cross Point Venture Partners in Silicon Valley to produce prototypes of its proprietary Magline vehicle and track, which were built in Santa Barbara, Calif.

Corns said Magline is third generation technology because of the HSPS technology and the two inch vertical levitation gap, which is much larger than existing systems.

The larger levitation gap will reduce construction costs of the substructure and allow the use of lighter tracks, as there is no longer a need for close-tolerance track alignment.

According to Corns, HSPS technology applied to Maglev transportation is analogous to the invention of the automatic switchboard. With the first manual switchboards in the 1870s, operators used plugs to connect the line between the caller and the person being called.

The first automatic switchboards in the early 1890s used a dial telephone to send electric pulses down the line to the central switch, where they were detected and used to make an automatic connection.

The same technology, which operates much like a computer, enabled the creation of the internet.

1/4

Photo:

2/4

3/4

Recent Comments

comments for this post are closed