Whether it’s going for a scenic bike ride under its massive green trusses, crossing the water to start a weekend snowboarding on the North Shore or seeing its long cables after a stint abroad, locals have a connection with Vancouver’s Lions Gate Bridge.

“Everyone who grew up here has a bridge story,” said Donald Luxton, principal of Donald Luxton & Associates and co-author of the book entitled Lions Gate.

The bridge opened in 1938 and is named after the nearby iconic Lions North Shore peaks. It was once nearly replaced but what happened instead was a legacy of innovation.

Luxton explained that the story of the bridge hinges on an enigmatic Vancouver figure named Alfred Taylor who had a dream of building a bridge to the North Shore. Taylor, an engineer and businessman, sparred for years with government and marine officials over the details of the bridge but never gave up on the project. His determination paid off when the bridge got the blessing of Prime Minister William Lyon Mackenzie King.

“It was years of difficult political clashing,” Luxton said.

Taylor was also able to find backers to fund the $6 million project and spend $4 million to develop North Shore land. The funding famously came from the British Guinness family whose descendants still own large chunks of north shore property. Taylor’s ashes were scattered from his beloved bridge, in accordance with a request he made on his deathbed.

“I stand by the fact that this bridge is our icon, it is our golden gate, Eiffel Tower, our Big Ben. People have forgotten we almost lost it,” said Luxton.

For legendary Vancouver engineer Peter Buckland, his legacy is tied to the Lions Gate Bridge from the 1970s and on.

Buckland said the bridge was the longest span suspension bridge in the British Commonwealth at the time. It was also the longest bridge anywhere at that time to have spiral-wound steel wire strands for the main cables, instead of parallel wires.

“It was a very good design for those days,” he said. “Very light, very efficient.”

Buckland & Taylor (B&T — now COWI) was asked in 1972 to look at ways to replace the concrete deck on the long approach viaduct that connects the North Shore to the suspension bridge proper. This work was done in 1975.

“The difficulty was that it would take days, rather than hours, to jack-hammer the existing concrete from the transverse beams that supported it, clean up the beams, place formwork, place reinforcing steel, pour concrete and allow it to cure, all before traffic could use the bridge,” said Buckland.

“And it could not be done a lane at a time. The delays to traffic would have been completely unacceptable.”

1/3

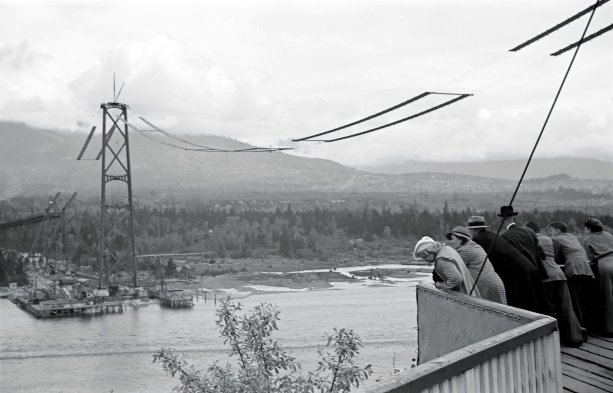

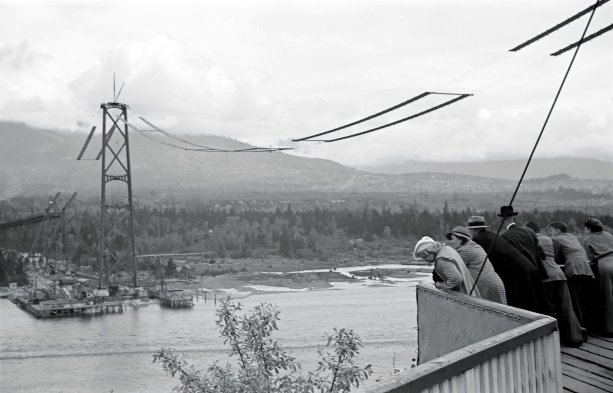

CITY OF VANCOUVER ARCHIVES — Passersby watch as the Lions Gate Bridge begins to take shape over Burrard Inlet.

2/3

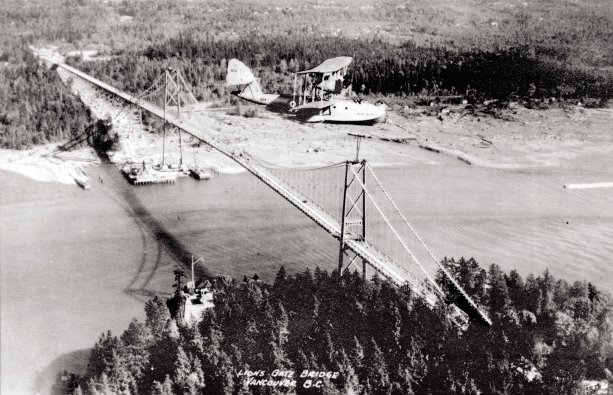

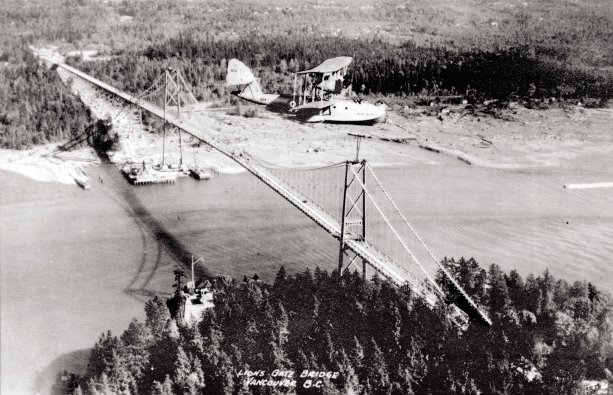

CITY OF VANCOUVER ARCHIVES — An airplane passes over the Lions Gate Bridge in 1940, just a few years after its completion. The bridge connected Stanley Park to the North Shore and was famously financed by the Guinness family who made their fortune brewing beer.

3/3

CITY OF VANCOUVER ARCHIVES

B&T suggested that the deck should be lifted out in panels, and the transverse beams should come out with it, the whole lot would be replaced, a panel at a time, with an orthotropic steel deck fully prefabricated and paved, replacing a panel each night while the bridge was closed to all traffic. The new roadway was wider (although still three lanes), pedestrians were protected from traffic by a barrier on each side, proper drainage was provided, the surface of steel to be painted was reduced, and the viaduct was given proper paving that it had previously lacked.

“This technique had not, to our knowledge, been attempted before, but it was later used on a number of bridges, including Throgs Neck in New York, Golden Gate Bridge in California and Champlain Bridge in Quebec,” said Buckland.

Following their 1970s work, Buckland and his team were asked if they could add thicker paving to the deck because it kept wearing off. Buckland said he needed to check the bridge’s strength first so they began to examine the three main suspension spans of the crossing, which led to a new technique called analyze and survey.

To determine its condition, the bridge was modelled in a computer as it had been built, including all known changes to the structure since its intiial construction. The bridge was then surveyed, but the observed geometry of the bridge was not as predicted by the computer model. In very broad terms, the centre of the bridge was lower than expected.

The explanation was that the main cables had stretched and the bridge’s spiral strands were found to have experienced the same type of stretch.

Another innovation that came from Buckland’s work was with traffic loading. There was concern that the traffic loading for which the bridge had been designed was very light compared to other bridges around the world. As there was no known way of predicting the traffic loading on a long-span bridge, a team of University of British Columbia professors and engineers came up with two methods that became the basis of both the American and the Canadian bridge design codes.

In 1995 the province announced the bridge would have to either be repaired or replaced. And when Luxton saw little discussion from officials about preserving the historic bridge, he and others at Heritage Vancouver began a campaign to save it.

“For five years I was the spokesperson for the bridge,” said Luxton. “It is national icon and I can’t image the city without it.”

In 1998 the province relented and agreed to fix the bridge rather than replace it.

Buckland’s team was involved from 1999 to 2002 in replacing the deck on the suspended spans. They decided to replace the entire suspended structure that hangs from the main cables, but this had to be done during short (10-hour) closures of the bridge at night, a procedure that had never been attempted before. Panels were carefully designed for quick replacement, and the details were tolerant of possible errors in the fabrication.

“We learned so much about suspension bridge design,” Buckland said.

The new structure is about 35 per cent wider than the old, providing wider lanes and sidewalks. It also carries epoxy asphalt paving where there was none before. Despite these extras, the weight was not increased, and again the area of steel to be painted was reduced by about 50 per cent. In addition, the new structure is entirely beneath the deck, sheltered to a large extent from rain and deicing salt spray.

To keep the weight down, the new structure has tubular members, and to ensure that there would not be long-term deterioration from repetitive loading, samples of the proposed welded connections were tested at the University of Karlsruhe in Germany, a leading research centre for tubular structures.

The project paved the way for the same type of operation on the similar, but even more challenging, Angus L. Macdonald Bridge in Halifax which is now nearing completion.

“I’ve hardly had a job I’ve worked on in my 55 years where almost everything we touched led to innovation,” Buckland said.

1/4

CITY OF VANCOUVER ARCHIVES

2/4

CITY OF VANCOUVER ARCHIVES — An airplane passes over the Lions Gate Bridge in 1940, just a few years after its completion. The bridge connected Stanley Park to the North Shore and was famously financed by the Guinness family who made their fortune brewing beer.

3/4

Photo: City of Vancouver Archives

Recent Comments

comments for this post are closed