The rising cost of demolition on the West Coast is one reason that the idea of moving buildings off their foundations to new lots could be a viable alternative to tearing them down.

A case in point: The recent demolition of a 2,000-square-foot house in Victoria cost about $68,000 – including $20,000 or so to remove the vermiculite insulation. That price could be as much as moving a house on a truck or even a barge to a new lot miles away, says Jimmy Connelly, manager of sales and estimating, Nickel Bros – a B.C.-based structural moving contractor.

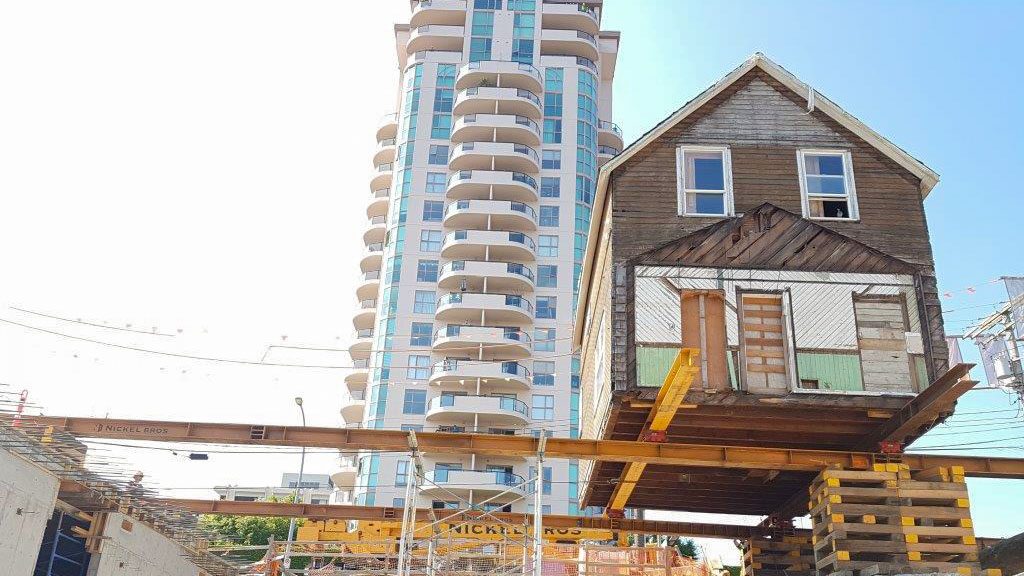

Founded over 60 years ago, the contractor has moved up to 100 houses to new properties in a good year.

Connelly says provincial and municipal regulations have made it tough to tear down buildings. Materials must be sorted and separated into various waste and recycling streams – a time-consuming and labour intensive process.

“You can’t just mulch everything into a dumpster anymore.”

Factor in the cost of removing hazardous materials and demolition gets costly. “You can spend $30,000-$50,000 taking the asbestos out of a building, prior to demolition.”

Still, Connelly says, construction and demolition debris typically represent about a third of all landfill refuse.

Connelly gets a spate of calls every month to evaluate houses for moves up and down the West Coast of B.C. As land values increase, older homes (and sometimes even newer custom ones) on large lots are facing the wrecker’s ball to make way for multi-residential projects.

He says about 50 per cent of the houses Nickel Bros evaluates are not moveable because of “route obstacles” such as trees and other buildings.

Only about a third of the homes he sees are candidates for the rigours of a move. “There are some buildings we refer to as a salad: they have been added onto and onto . . . structurally they are not very good,” says Connelly, noting Nickel Bros has a staff of engineers, route surveyors, estimators, equipment mechanics and skilled moving crews.

Prior to raising a building, utility services are disconnected and often using a diamond saw, the base is cut free from the foundation. The contractor uses a unified hydraulic jack system — each jack founded on a 5’x5’ engineered crib to “disperse the weight” of the building and ensure a balanced load. Safety is paramount and every move is carefully engineered. “It’s safer than farming or fishing.”

Wood-frame buildings are often the most straightforward to move but Nickel Bros isn’t shy about moving buildings made of masonry and other materials.

Moves are often done at night on roads to meet government requirements. About 60 per cent of the contractor’s moves are across waterways on barges – often to Gulf Island properties.

Connelly says a typical home weighs 40-50 tonnes – 950 tonnes less than the capacity of a barge – so load stability is never an issue. However, wind can cause a barge “to become a bit of a sailboat.”

About 25 per cent of the homes Nickel Bros moves are historic; many others are later-model bungalows and in the past decade or so high-end custom homes are finding new lots. In one case it moved a house valued at more than $5.5 million.

Connelly says the house-moving industry has successfully lobbied for a number of building code revisions to allow homes “to be treated as existing buildings,” rather than face expensive retrofits to meet modern code standards.

While municipalities want high-efficiency buildings, some of them “fail to understand that there are a lot of young people and families who simply can’t afford to spend that kind of money and time.”

He says it can cost three or four times more a square foot to build a new home, than relocate an older one on a new lot. Furthermore, it can take months less time to be move-in ready than it takes to build a new house.

What’s more, the work can be ennobling, says Connelly. “People see us taking their (community’s) buildings away and yet they applaud us because they are sick and tired of demolition.”

Recent Comments

comments for this post are closed