The three projects earning Vancouver Regional Construction Association (VRCA) Silver Awards of Excellence in the category of trade contractor for projects over $10 million tested the skills, expertise and ingenuity of project managers and crews through challenges ranging from COVID-19 to project changes.

The winners are Brymark Installations for the $72 million Neptune Allison project; Southwest Contracting Ltd. for the $19 million North Shore Conveyance project; and Whitemud Ironworks Ltd. for the $18 million The Post renovation.

A VRCA Gold winner will be chosen from the three at the gala awards dinner on Oct. 26.

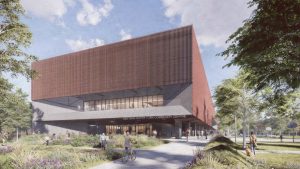

The Post is an extensive remake of Vancouver’s former landmark post office and is now billed as the largest single office building in the downtown.

The work by the general contractor involved refurbishing the historical structure and adding two twin towers, 17 and 18 storeys. The building will house 6,000 Amazon staff in 2023 as it leases 1.1 million square feet of office space as a sole corporation.

Whitemud Ironwork was the steel trade contractor.

Project manager Thomas Cote said the project was “fast-tracked” with the building design details unfolding as the project progressed and there was the constant need to accommodate to these changes. “Many changes came to us revising structural layouts, adding and deleting steel and changing scope,” Cote said via email. “As a result, this increases the amount of management required to control and execute the changes while still maintaining the contract schedule.”

Changes would often occur several floors above where his crew was placing steel.

As the project was a combination of renovation and new-build, different methods of steel construction were required.

Not only did the architecture’s intent have to line up with the actual site conditions but also key interface points.

“Lots of measurements need to be taken to correctly interface the structural steel with the site surrounding and connection points,” he said.

Many internal co-ordination meetings with the team took place to review changes, adapt to the design and accommodate site conditions.

Trenching while still providing a safe operating environment was the major challenge on Southwest Contracting’s (SWC) North Shore Conveyance project.

SWC subcontracted to Michels Canada to perform installation of 750 metres of 2,100 millimetre diameter sewage conveyance pipe, 600 metres of 900 millimetre HDPE forcemain and the retrieval of a malfunctioned tunnel boring machine from under West 1st Street in North Vancouver. The steel pipe was installed at depths ranging from 3.5 to 8.5 metres.

The ground conditions were the challenge, said SWC general manager Arash Foadi, describing the project.

“Soil conditions in this area of North Vancouver consist of lots of rounded gravel and cobbles, with the voids in between them mostly being sand and some silt. This material does not stand up very well,” he said.

Plus, the trench digging yielded ground water of two to three metres.

“On top of this we had a 60-year-old 1,350 millimetre diameter concrete sewermain (North Vancouver Interceptor) one metre away on one side and the CN Rail track, as close as 3.5 metres on the other side,” he said, adding the crew could not afford the type of ground movement caused by trenching.

Foadi said conventional shoring techniques including pile driving were explored but were abandoned after being not viable, too expensive or too time consuming.

A solution was needed. In collaboration with hired geotechnical firm Frontera, SWC used a modified method it had previously found successful and ensured the safety of the public, traffic, aging underground utilities, rail infrastructure and site access.

“The solution consisted of preconditioning the ground on the outside of where the trench shoring cage would eventually go, with 4:1 battered grout columns, to ensure the ground is stable while it is being excavated and pipe is being lowered in,” he said. “Once the pipe was in place, workers unhooked the pipe from the excavator from the top of the trench, then the shoring cage was installed over the pipe, and annulus between the cage and ground was backfilled. At this time, worker entry was allowed in the trench.”

Brymark Installations Group’s $72 million Neptune Allison project was the second phase of a capacity upgrade which will nearly double coal handling at the North Shore terminal.

Brymark’s scope of work included preassembling of structural modifications and outfit with all associated mechanical equipment and piping.

As well, the company was charged with the installation of a new rotary railcar dumper, indexer and associated dust collection system, and a conveyor system from the dumper to the storage yard, including a transfer tower module and six convey truss modules, construction of a ship loader transfer tower, drive station and assisting in the installation of a new quadrant ship loader.

Demolition of an existing quadrant ship loader was also included.

Challenges on the project included working within the confines of COVID-19 restrictions, an extremely small congested worksite, co-ordinating with many other subcontractors and carrying out the work while a live plant was operating and receiving rail and ship loading operations.

Recent Comments

comments for this post are closed