Is digital twin (DT) technology really a driving force for industry or just the latest hype?

That question was posed by Burkhard Boeckem, Chief Technology Officer of Hexagon AB, a multinational industrial technology company headquartered in Stockholm, Sweden.

Hexagon has good reason to find out. The company is a global supplier of digital reality solutions that combine sensor, software and autonomous technologies with the objective of “boosting efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector and mobility applications.”

Hexagon conducted Interviews with 660 “C-suite executives” across 11 industries to learn how leading companies are adopting DTs into their operations. Overall, 62 per cent felt there was immense value to be gained from DTs, particularly in terms of improved efficiency. Eight out of 10 felt DT technology had helped their operations reduce carbon emissions.

This type of response from current DT users suggests significant gains for the construction industry.

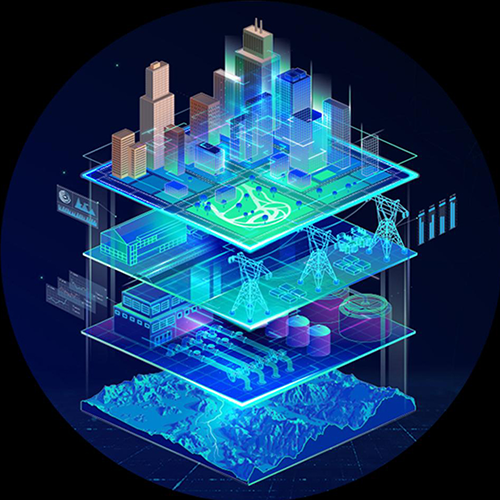

A DT is a precise digital representation of the physical world that uses dynamic data to simulate, analyze, monitor and optimize performance. In construction, it has numerous applications before, during and after the construction of a project.

“Digital twin technology in construction goes beyond visualization,” says Cyprus-based software solutions provider Program-Ace. “It is about creating a responsive, interactive model that evolves alongside the physical structure. This technology enables construction professionals to pre-emptively identify potential issues, optimize designs and improve decision-making processes. Using digital twin building technology, construction projects become more efficient, cost-effective and sustainable.”

The vast majority of Hexagon survey respondents have become more interested in DT technology since AI has arrived on the scene. The concept of “democratizing access to key information” was particularly appealing.

“Easing access is almost as important as having the data in the first place,” commented Johannes Maunz, vice-president of AI at Hexagon. “The most attractive digital twins are making use of LLMs (Large Language Models) to let people onsite or in the field access data in an easier form.”

The survey report also set out to dispel “myths” that surround the adoption of advanced technologies like DTs. One is that the technology threatens to displace human decision-making.

“Our data suggests not. While over half of respondents say their digital twins can make at least some decisions previously made by humans, a greater percentage say they are informing human decision-makers.”

Other myths that were addressed and largely dispelled concerned whether a digital transition must be perfect and complete from the outset, and that implementation costs will exceed budgeted allowances.

However, the pace of DT adoption varies greatly by industry. AEC (architecture, engineering, and construction) finds itself near the bottom in terms of perceived value (45 per cent) and overall technology maturity (25 per cent). Compare that with aerospace and defense (around 78 and 58 percent) or even general manufacturing (43 and 73 per cent). Despite the inherent differences between those industries, there is clearly room for improvement if AEC hopes to reach the levels of efficiency and productivity being realised elsewhere.

Why is AEC ranked so low?

Joshua Marriott, director of virtual design and construction at Arizona-based AEC firm The Weitz Company, said in the Hexagon report architects and engineers, construction firms and even clients themselves, “often have different expectations for what a digital twin should comprise.”

This disconnect could be slowing widespread adoption.

Yet among those AEC firms that have adopted DTs, the value created in terms of cost reductions, revenue growth, carbon emission reductions and projected annual ROI are consistent with the other 11 surveyed industry groups.

DTs hold huge promise for small and medium businesses with annual revenues below $50 million, the study concludes.

“Even a small-scale digital twin can deliver mighty benefits. Step-by-step enhancement can increase that value — at a pace that suits your organization,” says Frank Suykens, senior VP of visual computing at

Hexagon AB. “As you add more data and integrate the twin further into your organisation, you will see a process of incremental gains.”

John Bleasby is a freelance writer. Send comments and Inside Innovation column ideas to editor@dailycommercialnews.com.

Recent Comments