Designing and then installing the structural steel support system for a readapted heritage building in a downtown Toronto building might be compared to grappling with a giant crossword puzzle if not a Rubik’s cube.

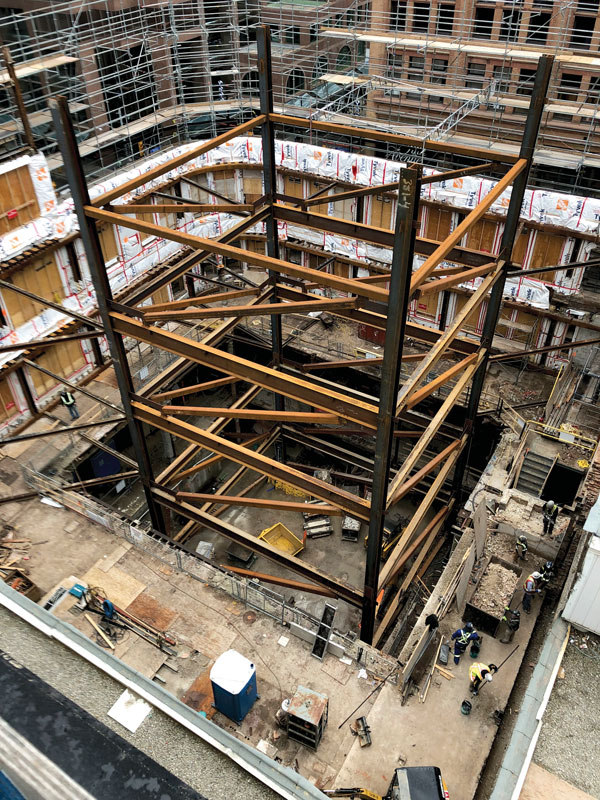

“This is unlike any other steel job in the city,” says Cadillac Fairview’s senior director of project management, David Stewart on the hurdles of installing a 130-metric-tonne (145-tonne) shoring tower at its Two Queen Street project.

Overseen by construction manager PCL Constructors Canada Inc., the project encompasses the restoration of the five-storey 1897 former Philip Jamieson Building and the erection of a three-storey glass addition and a (659-square-metre) 7,100-square-foot green roof.

In this particular undertaking the complexities — with more than a few twists and turns — stem from both the building’s location and the dual purpose of the shoring tower which is providing temporary support for a heritage facade being restored and permanent support for the superstructure.

As the building is located at the busy intersection of Yonge and Queen Streets in close proximity to the city’s subway system, erecting an exterior structural steel system wasn’t feasible.

“We couldn’t put the tower on the outside of the building,” says Nathan Bissell, design engineer with structural consultant Read Jones Christoffersen (RJC) Ltd.

But there was a Catch-22 situation. Inserting the tower inside the building came with a whole other set of other challenges because it would require tearing open the floors of the building and, as Bissell explains, “the floors were supporting the heritage wall.”

The design solution which structural engineering consultants RJC recommended to PCL and steel fabricator/erector Walters Inc. was a carefully selected large opening from the roof straight to the basement so the various steel components could be dropped into the building.

A complication with that option was that the existing footings were, more or less, in the same location as the shore tower columns. The answer was to install half footings for the south columns to take the load off the old footings and then completing the new ones, says Bissell.

Another major task was lifting a 500-tonne crane on to parking level five of the adjacent Eaton Centre shopping complex so that the various pieces could be lowered through the opening. To accomplish that goal, subcontractor Morrow Equipment used a 350-tonne crane to raise the larger one onto a protected crane frame Walters had built on that level.

“All four lanes on Yonge Street were closed from Friday night to Sunday night over two weekends last September to complete the lift,” says PCL’s project manager Cody Halbot.

On the following Monday morning, Walters Inc. began a four-month-long carefully sequenced operation of lowering approximately 200 pieces of steel down through the opening to the appropriate floors of the existing building and then the building of the tower, says project manager Jamie Hebb.

“Main assemblies had to be kept small enough to fit through the hole and to navigate into place over the existing floors. We also had to be cautious we didn’t overload the floors with too much weight.”

The shoring tower consists of five rows of HSS walers, each with eight props, which extend to support the heritage wall. Installing the wall plates and the waler system turned out to be one of the most challenging tasks as the structural (steel) design was complete before most of the wall was opened up. That led to what Hebb describes as a “significant amount of creative engineering to accommodate various as-built conditions.”

In other words, some sections such as window plates weren’t always were they were expected.

By the end of last December, the erection of the shoring tower had been completed. It consists of the four columns and 20 horizontal beams which remain as permanent steel and 20 temporary braces. Walters is now fabricating an additional tier of columns which will sit on top of the existing tower and support the addition.

Installation will start in early January and then, in either late spring or early summer when Two Queen Street is fully constructed, the braces and three rows of the walers will be removed, he says.

The entire undertaking required close co-ordination between the various parties to reach a successful completion, says PCL’s Halbot.

Recent Comments

comments for this post are closed