Constructors casting about for ways to increase efficiencies and minimize costs during the post-COVID-19 era should aggressively explore new streams of innovation, trade contractors were told during a recent webinar presentation on new technology.

Colorado-based construction IT guru Jeff Sample told Mechanical Contractors Association of Canada (MCAC) members participating in a business development webinar May 27 that it’s always a good time to expand mindsets but it’s going to be especially important coming out of the pandemic.

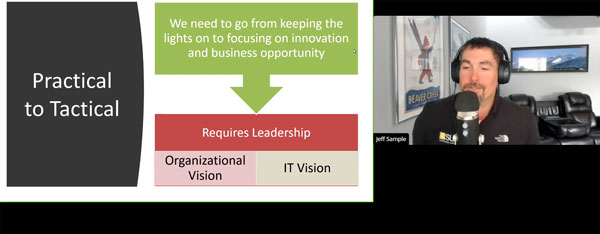

“I want you to change your mindset and COVID has brought that to the forefront,” said Sample.

Now is the time to shed over-cautious thinking at top management levels when innovative ideas are presented, with bosses who instinctively chip away at proposed tech solutions by asking how much it will cost and how long it will take, he said.

“The only way to survive this game is to keep on playing it, after the disaster, after the pandemic.”

Trade contractors should seek a more prominent place at the design table, Sample said, to enable them to more fully seize opportunities for innovation.

Sample, director of media for JBKnowledge and a consultant with eSub Construction Software, is an advocate for integrated labour delivery (ILD), a system that promotes integration of all participants in a project early on. Usually, a trade contractor who might wish to innovate through prefabrication or design for manufacture and assembly (DFMA) has to sit and wait until they get handed final design documents.

“We’d like to help you guys get to the table earlier to influence the design,” Sample said.

“With ILD, everybody is on the same page and at the table early so we can influence the design to enable prefabrication, modularization, off-site assembly.

“Everybody with knowledge of the project should be at the table so we can start solving a problem.”

Sample distinguished ILD from its more familiar counterpart, integrated project delivery (IPD).

“You have heard of IPD, that is a contractual relationship. What we need is a cultural relationship, that’s what ILD is.”

The efficiency and cost gains from prefabrication are significant, Sample said, showing slides to make his point. Comparing manufacturing times in one study, the average time to manufacture a prefabricated unit was 30.9 hours per unit, while with stickbuilt it took 48 hours per unit.

Manufacturing a single clevis hanger took three minutes in the shop, 10 minutes in the field.

The labour cost per unit in the shop was $75 per hour, while in the field it was $110 per hour.

Sample’s firm eSUB offers software services for all steps of the construction process and recently announced that platforms designed specifically to address the workflows of trade contractors would be integrated with PlanGrid and BIM 360 from Autodesk.

“How do growing companies work together? You have your accounting software, your field software and design and fabrication and estimating software,” said Sample. “They all need to be working together.

“People say it is not possible. I am here to say it is possible, and multiple companies are doing this in lots of different places with lots of different examples.”

But simply purchasing software is not going to be a silver bullet that solves all problems, Sample said. Firms need to embrace new attitudes and become more flexible and nimble rather than just throwing money at software.

“The number one mistake people make is they think it (new software) is a panacea and they will get everything out of their software and it will solve all their problems,” he explained. “They don’t do a good job of deciding what their problems are and they apply technology that doesn’t necessarily fit the problems and the workflows that they have.”

Other systems that enable improved partner collaboration are virtual design and construction (VDC) and Building Information Modeling (BIM). VDC is the management of integrated multi-disciplinary performance models of design-construction projects, including the product, work processes and organization of the design, Sample explained.

BIM, the darling of new technologies in the sector, will become even more valuable in the post-COVID era, he said.

“Like you guys need any more reasons to go to BIM,” Sample said.

“When the model goes to the constructability phase is how I define it, you co-ordinate with BIM, you co-ordinate with trade stacking, and understanding where we are and being efficient, it is huge.”

Follow the author on Twitter @DonWall_DCN.

Recent Comments

comments for this post are closed