South Africa is becoming an increasingly noisy country, due to the rapid densification of urban areas.

Noise Barriers

south africa

South Africa is becoming an increasingly noisy country, due to the rapid densification of urban areas. New townships, densification of suburbs, a growing demand for new housing and an ever increasing population are causing further residential growth in noisy locations, as well as construction of highways cutting through previously quiet suburbs and an increase of traffic volume on most roads.

Says Adrian Jongens from Jongens Keet Associates, Cape Town based acoustical consultants, “Town planning is compromised in the sense that dwellings are closer to roads that were not meant to carry large volumes of traffic, and previously peaceful neighbourhoods are now noisier than ever before.”

Noise pollution affects the entire globe. The WHO guidelines state that in the European Union about 40% of the population is exposed to road traffic noise with an equivalent sound pressure level exceeding 55 dBA (Decibels) daytime; and 20% is exposed to levels exceeding 65 dBA (Lambert & Vallet 19 1994).

When all transportation noise is considered, about half of all European Union citizens live in zones that do not ensure acoustical comfort to residents. At night, it is estimated that more than 30% is exposed to equivalent sound pressure levels exceeding 55 dBA, which are disturbing to sleep.

The noise pollution problem is also severe in the cities of developing countries and is caused mainly by traffic. Data collected, by the WHO researchers, alongside densely traveled roads were found to have equivalent sound pressure levels for 24 hours of 75–80 dBA.

How concrete acoustic barriers work

According to British Precast, trade body for the United Kingdom precast concrete industry, one very effective way to reduce levels of noise alongside a busy section of highway is by placing a barrier – a solid obstruction – in the direct path between the source and receiver that significantly reflects (transmitting it back across the highway) the sound energy reaching the receiver.

Highway noise barriers can effectively reduce noise levels by five to ten dBA, cutting the loudness of traffic noise by as much as 50 per cent.

However, the pressure waves hitting the top of the barrier will be diffracted downwards and some of this sound will still be received. A small amount of the incident sound may also pass through the barrier which needs to be sufficiently dense (at least 20kg per m2) and continuous to reduce this directly transmitted sound to an insignificant level compared with the sound diffracted at the top of the barrier. Concrete and masonry are ideal materials for this, as their inherent mass will always meet this requirement.

The key acoustic considerations are the height and length of the required barrier. A noise barrier can achieve a 5 dBA noise level reduction, when it is tall enough to break the line-of-sight from the highway to the home or receiver. After it breaks the line-of-sight, it can achieve approximately 1.5 dBA of additional noise level reduction for each metre of barrier height.

In addition, its length must extend far beyond the area to be protected to avoid its performance being compromised by noise diffracted around the ends of the barrier.

Barrier location is also a vital decision. Optimum performance can be achieved by maximising the difference between the direct line between the source and the receiver and the diffracted path over the top of the barrier.

On level ground it is normally desirable to place barriers as close as possible to the noise source, but where roads and railways are in cuttings or an embankment, placing the barrier further away at the top of the slope is usually the best solution.

Interlocking concrete block retaining walls

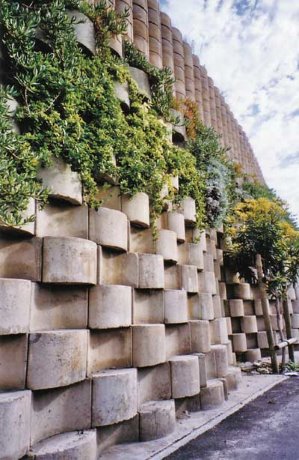

Pre-cast interlocking concrete blocks, such as those supplied by Terraforce, a well-known local concrete block manufacturer, lend themselves ideally to the construction of highway noise barriers.

Terraforce blocks, having undergone rigorous testing in Canada and the United States, comply with I.C.B.O. (International Conference of Building Officials) standards (2000), and provide inherent properties of strength, durability and versatility that allow for aesthetically pleasing and cost effective noise barrier designs. Not only are they easy to maintain and resistant to rot, vermin, vandalism and fire, but they are also plant friendly, hollow concrete blocks that can be filled with a planting medium to accommodate suitable plants.

An example of a Terraforce retaining wall effectively reducing noise pollution would be the Stanhope Road Barrier Project in Cape Town, undertaken in 1999. During this time, the old noise regulations had just taken effect, requiring Manong and Associates, a Cape Town based Civil, Structural and Developmental Engineering firm, to implement a noise barrier next to some high density residential units – the Doncaster Apartment building – at the same time Stanhope Road was to be upgraded and re-aligned.

The completed noise barrier, constructed using Terraforce L11 blocks, works by reflecting noise back across Stanhope Road. To minimise an increase in noise on the opposite side of the road the lower section of the retaining wall was constructed at an angle to reflect the noise upwards to pass above any possible receivers on the other side. A sub-set of this type of barrier includes a range of modifications to the top edge, such as wide flattops and multiple vertical edges to reduce the level of diffraction.

Barriers can also be formed from earth mounds or “berms” along the road, or from a combination of earth berms and walls. Earth berms have a very natural appearance and are usually attractive. They also reduce noise by approximately 3 dB more than vertical walls of the same height. However, earth berms can require a lot of land to construct, especially if they are very tall.

Such a noise barrier recently won one of four Concrete Manufacturers Association (CMA) Premier Awards, the Cathay Pigments Trophy, as well as receiving regional and national awards in the Retaining Wall Elements category, having impressed the judges as “an innovative and ecological application which dampens the noise levels and prevents problems due to drifting sand dunes”.

The barrier, designed by Planning Partners, Cape Town based landscape architects, was constructed adjacent to a new development within Century City complex that is located next to busy Ratanga Road, connecting the N1 highway with Montagu Gardens Industrial estate.

In order to protect future residents from excessive traffic noise from a planned double carriage highway and any possible negative visual impact associated with this, a 4.5 metre high and 500m long earth berm was created with the surplus site material. To reduce the footprint of this structure and to improve noise absorption capability, a steep Terraforce embankment with three terraces of varying widths was built on the road facing side. A subsoil drainage system was located behind the bottom row of the blocks and the earth backfill reinforced with polytex 115 geofabric on every third row of blocks.

The retaining wall runs all along the full boundary length of the road and instead of a standard single slope running at a 70% incline, it consists of three 1.5m terraces that each run at their own curvature line, breaking down the façade to accommodate plant pockets at different levels, to soften the overall appearance of the retaining wall.

The landscaping team used the terraces to good effect by creating almost instant hanging gardens with mostly water wise indigenous planting.

These hardy plants are fast growers and adapted to dry spells and high winds that can occur in this part of South Africa. They will also be very effective in preventing wind erosion on the sloping embankments facing the buildings.

Future Goals

Although some effort has been made to reduce the level of noise in our communities, it is still not enough. Jonges is of the opinion that until road builders are told to build quieter roads, traffic noise level will not decrease.

He points out Holland as a first-rate example of a country that has achieved, through awareness and strict legislation, acceptable community noise levels. “Holland is one of the quietest places to be, even though it has the highest density of population per land area. And why? Because money was spent on creating the necessary awareness amongst the general population and key decision makers!”

The WHO says that a major step forward in raising the awareness of both the public and of decision makers is the recommendation to concentrate more research and development on variables which have monetary consequences.

The Guidelines state, “that research should consider not only dose-response relationships between sound levels, but also politically relevant variables, such as noise-induced social handicap; reduced productivity; decreased performance in learning; workplace and school absenteeism; increased drug use; and accidents”.

For South Africa’s noise levels to reduce significantly many things need to happen, and some of the right steps are being taken. Yet one thing is clear – environmental noise barriers should become standard features around housing sites, being one of the more straightforward methods of cutting down noise – effectively.

An almost instant hanging garden was established by the landscape architects for this noise barrier, constructed using Terraforce L12 blocks.

Recent Comments

comments for this post are closed