The Girder-Slab System, a hybrid steel and precast concrete system allows for construction in cold-weather conditions that would delay conventional cast-in-place concrete construction methods, says an official with Supreme Steel Edmonton, the steel contractor for the Courtyard Marriott at the Edmonton International Airport.

But improvements over the years in cold-weather building technology and materials have opened up opportunities for builders in cold snaps. A case in point is in Edmonton where an unusual steel/precast concrete system is being used to construct an eight-storey, 178,000-square-foot Courtyard Marriott at the Edmonton International Airport.

The building consists of a structural steel system combined with precast concrete hollow core floor/roof slabs. The hybrid system allows for construction in cold-weather conditions that would delay conventional cast-in-place concrete construction methods, says Peter Timler, vice-president of engineering, Supreme Group, the parent company to Supreme Steel Edmonton, the steel contractor for the Marriott.

Called the Girder-Slab System (GS), it is the first time it has been used in Canada. Proponents see it as an alternative to cast-in-place concrete in conventional construction of midrise towers of four storeys or taller. GS is new to Canada, but in the U.S. close to 100 midrise residential buildings have been constructed since 2004 with the system. GS is produced by New Jersey-based Girder-Slab Technologies.

Originally, the Edmonton Marriott hotel design was conceived as a cast-in-place concrete structure. Supreme, however, showed the benefits of the encased steel floor frame within composite precast planking for gravity loading support, says Timler.

“The interesting part of the integrated design approach was that we managed the structural information. We modelled it, we managed it and we vetted it with the structural engineer (Williams Engineering Canada Inc.) who remained responsible for the structure,” explains Timler.

“It was a very collaborative approach that allowed us to get the design done in a very short time without any hitches.”

Timler says even the elevator and stair core for the building – typically done in cast-in-place concrete – was specified in structural steel to allow for a quicker construction schedule over winter.

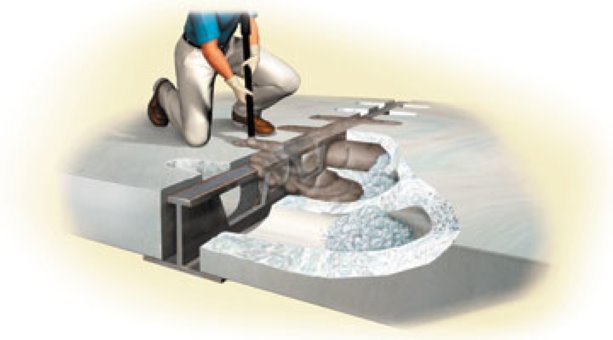

The GS system consists of a modified wide-flange section that accepts hollow-core planking on the bottom flange. Web openings in the steel D-beam allow for the hollow-core elements to be “stitched through” the steel for grouting and rebar, he explains. Precast hollow-core slabs for the job are being supplied by Armtec, of Richmond, B.C.

The benefits of GS go beyond cold-weather applications, explains Timler. Fewer trades are required, for example.

The steel and hollow-core erection only requires ironworkers. Conventional construction would call for multiple trades, including trades for the structure, deck, rebar, concrete placement and floor finishing, he says.

“Girder-Slab could add a 25 per cent time savings,” Timler says, noting that Supreme’s calculations indicate that on some two-year cast-in-place concrete projects GS could shave six months off build out.

GS has other attributes. It offers builders a safe working platform once planking is down. What’s more, the shoring required on each floor in cast-in-place construction isn’t required, he says. “That allows follow-up trades to come on site much sooner.”

The GS system is also cost-competitive with conventional construction and will probably save an owner money over cast-in-place concrete at the Marriott, the engineer points out.

No special training is required for installation of Girder-Slab but the steel contractor must accept more responsibility (not just fabrication and erection) for the project.

“The contractor has to look at the supply of the hollow-core slab and the grouting process.”

Timler says the economic downturn in 2008 that slammed the U.S. residential market slowed the spread of Girder-Slab construction.

“We were into the millions of square feet of various projects moving ahead when the downturn happened and they all got pulled back.”

Daniel G. Fisher, Sr., managing partner, Girder-Slab Technologies, sees the Marriott project in Edmonton as seminal.

“It is a tremendous opportunity to introduce owners and builders first hand to the benefits of structural steel and precast hollow-core slabs for multi-storey residential construction.”

Structural steel and precast concrete require a small crew of ironworkers to quickly erect the structure and continue work despite freezing temperatures, he adds.

Cast-place-concrete is still the simplest way for an architect to design a multi-storey residence.

“It gives the architect flexibility to place the columns where he likes.”

But hybrid systems like Girder-Slab are catching on in the U.S. because they are less expensive and quick to erect, Fisher adds.

Recent Comments

comments for this post are closed