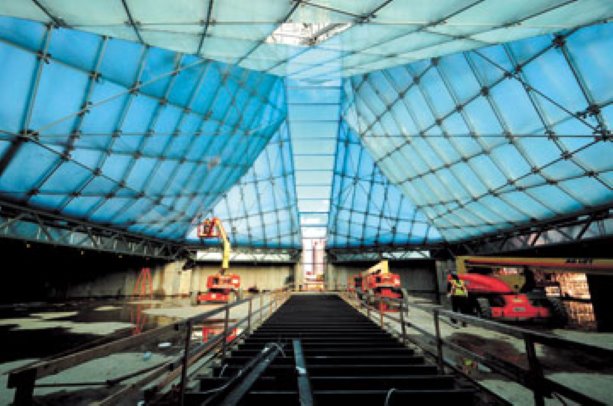

The soaring glass and steel roof of the prayer hall of the Ismaili Centre in the Toronto, Ontario neighbourhood of Don Mills, adjacent to the Aga Khan Museum, will be a visible reminder of the faith of its members who belong to the Shia Imami Ismaili Muslim community. Carillion is the construction manager overseeing the complex which was designed by Charles Correa Associates and Moriyama & Teshima Architects. The structural and building envelope consultant is Yolles, a CH2M HILL company.

“It is being built with a mixture of reinforcing concrete and structural steel,” says

Crispin Howes, a senior associate with Yolles.

Cast-in-place concrete was the most economical choice for the lower level and first floor, while structural steel was used for the roof of the second floor.

While natural light is used to highlight several significant areas, the most spectacular is the prayer hall roof. Measuring 30 metres by 30 metres and reaching 15 metres at its highest point, the roof is comprised of a double layer of translucent glass supported by 65 Vierendeel trusses. There are a total of 920 glass panels.

One layer of glass was point-fixed to the underside of the trusses, with the second layer attached on top of the trusses with the use of silicone gaskets. The space between the layers is a pressurized cavity to prevent condensation.

“There is obviously a high degree of integration between the steel and the glass and tolerances are quite high,” says Howes.

■ Daily Commercial News subscribers may view more information on Carillion and its projects by viewing company ID 6342in Reed Construction Data Canada Building Reports.

If you are not already a subscriber, you can be by filling out the form at this web page.

Building Reports are published daily in the Daily Commercial News. The Daily Top 10 Construction projects can be viewed online free of charge at the Reed Construction Data Canada Building Reports web page.

To learn more about construction project leads from Reed Construction Data, fill out the web form at this web page.

And that’s why Gartner Steel and Glass GmbH, the German-based international curtain wall producer which erected much of the cladding on the Royal Ontario Museum’s Michael Lee-Chin Crystal addition, was chosen for the project, he says.

Steel fabrication including trial assembly of the roof in sections in a workshop took about five months, says Gartner operations manager Stefan Zimmermann.

“However, it should be noted that the roof structure does not only consist of Vierendeel trusses. While these trusses are the main components, there are a lot of other steel parts which form part of the roof structure.”

The biggest parts of the structure are the edge beams, with the longest one extending 27.3 metres and weighing 10.9 metric tonnes, he says.

The glass panels were manufactured in Germany. But the trusses and other steel components were fabricated in the Czech Republic. While it has its own facility, the company frequently works with other European fabricators.

“The decision whether steel fabrication is done in house or with external fabricators depends on the workload of our own factory and type of work/structure.”

None of the trusses had to be cut or adjusted on site because they were fabricated to the final dimensions with tight tolerances in the factory. And the connections which had to be done on site were designed as bolted connections “in order to avoid site welding and to ensure highest precision.”

While Gartner Steel and Glass GmbH had one technical adviser on the site, the actual installation was organized and overseen by Josef Gartner USA supervisory staff.

Installation started in June 2011 and was substantially complete in late December, says Zimmermann.

Workers place silicon gaskets on the top chord of erected structural steel roof trusses at the Ismaili Centre in the Toronto neighbourhood of Don Mills. Carillion is the construction manager overseeing the complex which was designed by Charles Correa Associates and Moriyama & Teshima Architects.

Recent Comments

comments for this post are closed