Among Pure Technologies’ arsenal of pipe infrastructure testing products is SmartBall, a free-swimming inline leak detection device, designed to operate inside a working pipeline and a magnetic flux leakage (MFL) detector, an electromagnetic method of non-destructive testing, used to identify corrosion, pitting and wall loss in metallic pipelines.

Canadian technology providers continue to play an important role in the world’s battle against decaying water and sewage infrastructure. One such provider is Pure Technologies, with its head office in Calgary.

Among its arsenal of pipe infrastructure testing products is SmartBall, a free-swimming inline leak detection device, designed to operate inside a working pipeline and a magnetic flux leakage (MFL) detector, an electromagnetic method of non-destructive testing, used to identify corrosion, pitting and wall loss in metallic pipelines.

“SmartBall was developed and launched in 2007 to fill a market niche for an inline inspection tool that would bring an acoustic sensor directly to the leak location,” says Norvin Eitzen, marketing manager at Pure Technologies. “While some technologies could detect leaks in smaller diameter pipelines from outside the pipe, external devices have a problem hearing the leak noise due to the diameter of the pipe and how sound is dampened. These leak noises can be very low frequency and don’t travel down the water column very well—thus the need for localized listening.”

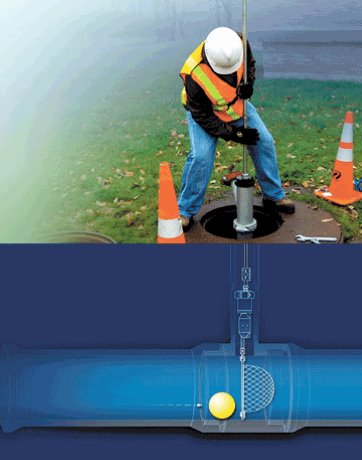

SmartBall is a foam ball with an instrument-filled aluminum alloy core. The device is inserted into a pipeline at one end, usually through a four-inch tap. Once inside the line, the device achieves its purpose using an integrated computer that listens for the acoustic signals of tiny water leaks. SmartBall may travel as many as several kilometres for up to 12 hours as it records the results of its inspection on a memory card. Strategically placed receivers spaced out on the outside of the pipe help to calculate the ball’s position and speed. The device is finally captured with a net inserted into the pipe at the other end.

“When we download the information into the computer, one of our analysts goes through the data to determine the exact locations of the leaks,” says Eitzen. “We can then show the clients exactly where the leaks are located along the length of the pipe and identify the magnitude of the leaks.”

The device also works on pressurized sewage lines, looking for gas pockets trapped along the pipeline.

“The bubbles can contain corrosive hydrogen sulfide that can eat away at the pipeline wall,” says Eitzen.

In Canada, the company has taken on contracts ranging from the cities of Calgary, Ottawa, Hamilton and London to the regions of Haldimand, Peel and York. U.S. clients include New Orleans, Miami-Dade County, and the Washington Suburban Sanitary Commission.

SmartBall has also been adapted to detect leaks in oil and gas pipelines.“Historically, the oil and gas industry has used a mass balance calculation that detects only very substantial leaks,” says Eitzen. “Our technology will pinpoint even the smallest leaks.”

Pure Technologies’ magnetic flux leakage (MFL) tool pulled a page out of the oil and gas industry and adapted it to water line use. The technology is based on the process of “pigging”—sending a device through an oil or gas pipeline to remove sedimentation and scale build-up. “Smart pigs” offered by the company generate an electromagnetic flux in metal oil and gas lines to evaluate their structural integrity, identifying pitting, corrosion and thinning pipe walls through distortions in the magnetic field.

“Our water line MFL tool is basically a water version of the smart pig for oil,” says Eitzen. “The technology works to detect pitting and corrosion, even through mortar liners as much as an inch thick.”

Unlike SmartBall, the MFL tool doesn’t travel through a live line. Instead, it’s pulled or winched through the target pipe, which is emptied of fluid. The tool must also be sized closely to the inner diameter of the pipe.

“We’ve created a broad range of sizes to accommodate the projects we’ve been working on,” says Eitzen. “In December, we performed an inspection of a pipeline in San Diego that ranged up to 76 inches in diameter. It’s now the largest MFL tool on the market.”

Recent Comments

comments for this post are closed