The material is called graphene and it boasts a strength 200 times that of steel. A coating of graphene just a few atoms thick has the potential to increase the strength of metals, including steel, by 100 times or more.

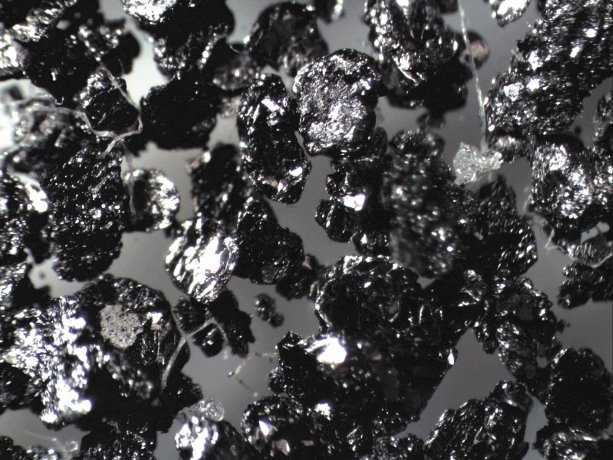

Graphene is derived from graphite, the carbon-based material used in pencil leads.

"Both are carbon-based materials, but graphite is a much less organized form of carbon closer to thermal coal than graphene," says A. Paul Gill, chief executive officer of Lomiko Metals, a B.C.-based resource company looking to secure high quality sources of graphene in Canada. "Graphene, on the other hand, has six carbon atoms forming a hexagonal structure, which makes it much closer to the strength of diamonds, with their tetrahedral structure."

This carbon formation is a single atom in depth, which is why graphene is considered a two-dimensional material. It was first separated from graphite about a decade ago. Current research has focused on producing large sheets of graphene from high-quality sources of graphite as economically as possible.

Product spin-offs may include anything from lighter, tougher sports equipment to flexible cell phones, super batteries, super-conductive materials for electronics and incredibly strong construction materials.

"I think what captured a lot of people’s imaginations in 2014 was research that indicated that a 10- to 100-nanometre thin layer of graphene could stop bullets more effectively than Kevlar," says Gill. "The use of graphene-coated steel could conceivably make lightweight military equipment that’s virtually invulnerable to bullets."

Previous efforts to strengthen metals using graphene had failed to exploit graphene’s strength. However, breakthrough research at the Korean Advanced Institute of Science and Technology used chemical vapour deposition, a chemical process, to create composite materials, marrying graphene to both copper and nickel. In the experiments, copper was made 500 times stronger and nickel 180 times as strong through the addition of only 0.00004 per cent graphene by material weight.

"Graphite currently sells for only about $500 a ton, while graphene commands about $1 million per ton," says Gill. "The reason that it could be economical to use to strengthen steel is that you could coat a surface area of steel the size of a football field using only about a kilogram of graphene. With the increased strength, you could also reduce the amount of actual steel used in construction."

More simply, polymer coatings containing graphene oxide could also be used to add strength and corrosion resistance to steel and other metals.

Lomiko’s potential markets for graphene include electronics companies and those supplying material for 3D, or additive, printing, such as Graphene 3D Lab, a recent Lomiko spin-off. Additive printing technology could see steel re-engineered and combined with graphene at the nano level and laser welded into structural steel, molecule by molecule.

While Canada possesses significant graphite resources, the US has few, relying largely on Canada and China for its supply. Developing large sources of high-carbon purity graphite capable of being converted to graphene domestically could prove lucrative for Canadian suppliers.

Lomiko has focused its exploration on prospecting for high quality flake graphite in Quebec. It’s currently concentrating its efforts on options on the Quatre Milles Graphite and La Loutre properties in southwestern Quebec.

"Our test holes at Quatre Milles have revealed high quality large-flake graphite of 94 to 99.99 per cent carbon purity," says Gill. "Bench tests at La Loutre are similar but further tests will show us more about its crystalline structure and carbon content. If we can find graphite trends that can produce 100,000 tons of graphene-quality graphite, that will allow us to expand into some of those really cool construction ideas like building a space ladder that will allow us to place objects in orbit. The scientists have done their part and now it’s time for the engineers to take over and exploit graphene’s construction possibilities."

Recent Comments

comments for this post are closed