About 35 kilometres west of Halifax in Nova Scotia’s South Shore, a roundabout, a new diamond interchange on Hwy. 103, three bridges and about four kilometres of road are nearing completion as part of a $17.1 million three-year project.

It is "quite a (financially) significant project" but there is good reason for it:

"It can accommodate the future twinning of the highway," explains Isaac Bou-Karam, project engineer of the province’s transportation and infrastructure renewal department.

The province is currently studying the possibility of twinning up to 300 kilometres of highways — a large injection of work for the province’s road building industry.

The new interchange is designed to tie into future twinning of Hwy 103. "There’s no timeline yet or confirmed funding but that can happen pretty quickly," says Bou-Karam.

Another reason for installing the Ingramport Interchange is that there is no interchange in the area for about 20 kilometres.

Bou-Karam says the Ingramport Interchange has a couple of innovative design solutions to old problems.

A case in point is the main bridge which has no surface joints — an integral abutment — which eliminates moisture infiltration. A standard design would incorporate a steel or asphalt plug joint which usually "loses bonding with adjacent material over time."

"Because we salt our roads and bridges, over time the salt gets into the steel causing corrosion. That causes the bridge deck to deteriorate," explains Bou-Karam.

A multitude of freeze-thaw cycles also results in potholing at the joints and wherever the steel is corroding, he says.

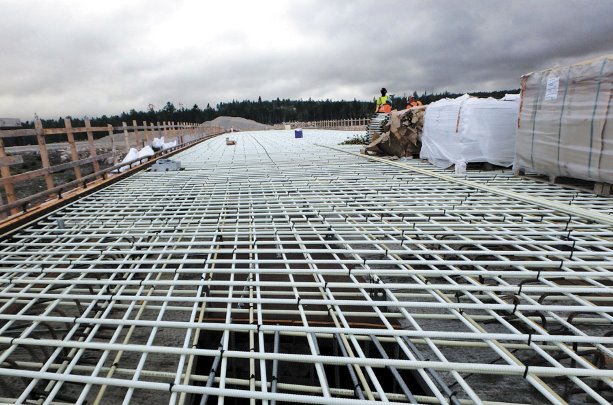

Another innovation is the bridge’s deck reinforcement which consists of glass fibre-reinforced polymer (GFRP), rather than traditional steel rebar, to further minimize future maintenance issues.

"There are no real tricks" to the installation of GFRP which is preformed to meet design specifications, Bou-Karam says.

While GFRP is "slightly more expensive," than steel reinforcing, pro-rated over years it is less expensive because it requires less maintenance.

The contract was done by Antigonish-based Alva Construction Ltd. which was awarded four contracts on the Ingramport Interchange including the subgrade of the connector road, the diamond interchange and a structure over Kelly Brook.

Dexter Construction completed the type one gravel, paving and trail bridge for pedestrians and ATV vehicles, underground drainage, signage and lighting.

The bridge span over Hwy. 103 is a 38-metre X 2 long reinforced concrete crossing.

GPS grade control was used on the project for accurate grading/excavating.

Bou-Karam says the site has more ground-source water than the original environmental assessment showed.

To mitigate sediment flow from the water, the builders installed a series of check damns, a silt fence and silt ponds with multiple sump pumps. They also used silt bags where there was no space for pools, hay mulching or hydroseeding.

"These are all measures used to mitigate erosion and sediment control," he says.

Part of the challenge was getting the public onside with the project – especially the roundabout which is not normally seen outside of urban areas, he says.

Dexter Construction was the general contractor for the roundabout and Halifax-based engineer CBCL Limited recently completed a feasibility study on eight sections of highway twinning around the province. The province is now headed to a series of public meetings for feedback.

Recent Comments

comments for this post are closed