Looking somewhat like an elegant tent frame, a gracefully curving structure on display at a special show in Toronto is a visual demonstration of the potential of 3-D printing in design and construction, say its creators.

Comprised of bending fabricated glass-reinforced polymer rods connected and held in place by a total of 12, 3-D printed nodes at the mid-way point and at its apex, the Mangrove is one of several exhibits at 3DXL, a large-scale 3-D printing exhibition sponsored and organized by the Design Exchange, a non-profit design museum.

This is the first-ever public presentation of the ultra-lightweight composite structure which was designed by architects Denegri Bessai Studio and Cast Connex, with input from Entuitive Engineering and Heliolytics.

"Each node has been engineered, shaped, and subdivided to suit 3-D printing materials and tolerances, while providing adequate structural support for the system," says Tom Bessai, Denegri Bessai principal.

The lower nodes were made from a material called ABS (Acrylonitrile butadiene styrene), while the apex nodes were fabricated from PLA (Polylactic Acid). One, though, was printed entirely in stainless steel.

Other features include a sensor and actuator circuit at each apex node which activates LED lighting when there are vibrations to the structure.

Unlike the other show models which were created entirely from 3-D printing, the Mangrove is a hybrid system, says Bessai.

"But construction isn’t about the use of one monolithic material."

Denegri Bessai is a small architectural research practice affiliated with the University of Toronto — where Bessai teaches part-time as an assistant professor with the John H. Daniels Faculty of Architecture, Landscape and Design — and also with Ryerson University.

"That affiliation gives us more independence to conduct research," says Bessai, explaining the creation of the Mangrove is an integral part of that research mandate.

It’s also a follow up to research he conducted in the 2012-13 academic year at the University of Michigan as part of the Master of Science in Material Systems Program.

"The Mangrove Structure picks up the work that I had initiated at UM (University of Michigan) on bundled bending-active structures that are lightweight and exist in an equilibrium bending-active state.

"We began with some scale models and prototypes and made the decision to integrate 3-D printing technology into the project via 3-D printed connectors/nodes," says Bessai on the design development which commenced in February of this year.

But the design and the subsequent fabrication was not a simple process. A series of physical modeling exercises, which gradually moved up to full-scale mock up and prototypes, was used to develop the form of the Mangrove

A major factor in determining that form was the limitations of a gallery where the 3DXL show is being held. The 11’6”-high Mangrove had to be custom designed to fit the ceiling height, says Bessai.

"Once we found a form that worked well within the space—allowing for adequate headroom, good circulation, and appropriate height of the 3-D printed elements—we digitized the model with a digitizing arm and began work on those elements."

A full-sized prototype was developed in collaboration with Cast Connex, a Toronto engineering firm specializing in designing structural components.

"In testing the nodes for the mangrove structure, we conducted a bend test on a full-scale sample node and rod. This investigation enabled us to refine the choice of adhesive and the design of the mechanical shear connections between the node segments," says Michael Gray, a principal and co-founder of the firm.

"We see 3-D printing as nascent technology that may represent an emerging trend in the construction industry," says Gray, in explaining why his company participated in the project.

"After settling on a final design for the Mangrove, we began a process of distributing printing on several different printers, with the assembly of the nodes at our studio," adds Bessai.

When asked to explain the importance of the project, Bessai points out the Mangrove is an ultra-light-weight structure which gains strength through the elastic bending of its primary structural elements and is: "instructive in showing the way forward in architecture and construction towards more efficient and graceful structures and minimal material use."

And this is not the end of the project. Denegri Bessai Studio is currently working on academic papers documenting the design and fabrication process that went into the Mangrove and plans to follow up with the design of more efficient and less expensive subsequent structures, he says.

After the 3DXL show ends, the Mangrove will be readapted then installed/ exhibited temporarily at the Wintergarden Theatre in Toronto this October as part of an international conference on advanced 3-D printing.

Other exhibits at 3DXL include Benjamin Dillenburger and Michael Hansmeyer’s Arabesque Wall, which was printed out of sand to create a monolithic structure in artificial sandstone, and Emerging Objects’ Saltygloo which was fabricated from binder and salt harvested from San Francisco Bay.

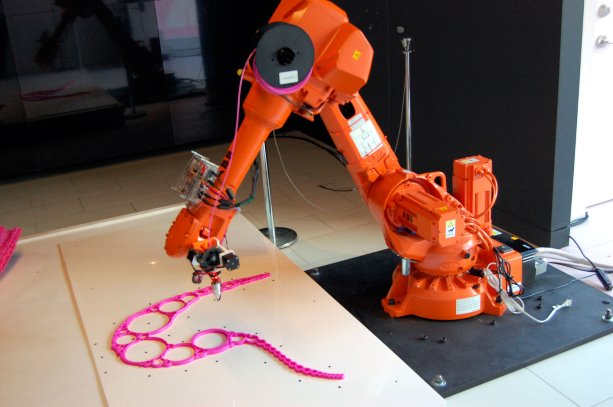

Another exhibit is SpaceWires, an experimental project by faculty and graduate students at the UCL Bartlett School of Architecture, London, which utilizes the six axis of an industrial robot to create a 3-D printer capable of creating sweeping curves in space.

The show concludes Aug. 16. For more information visit www.dx.org.

1/3

Photo:

2/3

Photo:

Recent Comments

comments for this post are closed