Other than a sign clearly visible to drivers on Highway 401 in west end Toronto, there is little indication of the role a cluster of industrial buildings performs in traffic movement throughout the province.

Wedged close to that highway and not easy to find for the uninitiated visitor, the Ministry of Transportation provincial sign shop fabricates approximately 70,000 to 80,000 traffic signs yearly.

A variety of vinyl reflective material is used to manufacture signs from various substrates, such as wood, steel and extruded aluminum, says sign shop head Paul Barbieri.

Sixteen employees including sign markers, office staff and shipping and receiving personnel work at the complex, which is comprised of an administration wing, a manufacturing plant and a shipping receiving/storage building.

A limited number of signs are also turned out at a small, four-employee North Bay, Ont. shop. But the overwhelming number of signs are fabricated in Toronto including all the extruded aluminum overhead signs and that can range from 300 to 500 a year, he says.

Using an array of computers, layout equipment, applicator presses and paint booths, the shop provides all provincial highway signs as well as ones for other ministries, regions and municipalities.

A major priority project was creating 1,700 signs for the 2015 Pan Am Games, he says.

"It worked out quite well," says Barbieri, explaining that a year of pre-planning ensured those signs were ready on time.

"We have to be self-supporting whether we sell signs to a contractor or to a different branch of the ministry."

By that he means the shop has to generate enough income to cover operating and material costs and wages so as not to go into a deficit position.

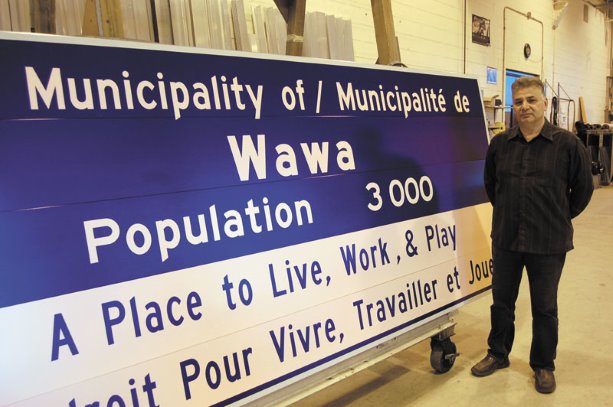

Paul Barbieri

MOT Provincial Sign Shop

Making the signs is a process that involves designing the text and symbols on a computer and then printing and cutting out reflective vinyl sheets — called legends — that are then applied to the various substrates.

In the case of the overhead extruded aluminum panels, a considerable amount of pre-layout work is required including washing the panels, snapping them together and installing z-bars which hold them in place, he says.

The production is divided into two categories: work orders and stock.

As the name implies, work orders are specific designed products where the colours, text and symbols are determined by the requirements of the customer, be it the MTO or a regional government.

Housed in the shipping/storage building, stock items are ones that don’t vary considerably, such as stop signs, which can be pulled off the rack and quickly transported. At any given time, there are approximately 180 different stock products on hand, he explains.

As well, the shop also makes overlays or slight alternations to still structurally sound signs. An example might be a municipality’s decision to replace its symbol or logo, without any other changes.

"We’ve been here since the mid 1960s and continue to serve road users across the province with high-quality work."

At one time, 11 such shops operated throughout Ontario, but those were closed down in the 1990s as part of cost-cutting and consolidation policy by the province, he says.

There have been other changes over the years as well, says Barbieri, who started working there 25 years ago and recalls having to physically adhere the lettering on site.

"Initially the signs were hand painted. Up until about 15 years ago, our staff was responsible for both manufacturing and installation of all signs. The sign installation has since been outsourced."

Another major evolution, and one that was first introduced about the same time as the consolidation, was an increased use of symbols rather than reliance on text in both ground and overhead signage.

"The symbols made it also easier for a growing diverse population to better understand the message."

Most signs have a life of between seven to 12 years, although some can last much longer, even up to 20 years.

"They are replaced when either the message changes, they are damaged, the reflectivity drops below standard, or when they go missing."

As Barbieri describes it, producing signs and meeting orders is both complex and challenging, but also very organized and co-ordinated.

"We ask for a six- to eight-week window," he says, referring to the time period contractors are asked to place orders before they need them.

If a contractor progresses faster than the construction schedule and the signs are needed earlier, then production at the shop can usually be altered to fit that schedule. Similarly, if there is a construction project delay, the sign pick up dates can be pushed back.

"But that means we have to store them," says Barbieiri, explaining that, at the height of the production period from March to late November/early December, space is at a premium.

Of course, that long ordering period doesn’t apply in instances where an existing sign is damaged or destroyed, such as in a car accident, he says. "We provide an immediate replacement."

Using high quality materials that are obtained through competitive bidding, the goal at the shop is always to strive to improve the operation, says Barbieri.

Recent Comments

comments for this post are closed