Engineers at the Ontario Ministry of Transportation (MTO), Eastern Region, have successfully completed the ministry’s first trial of heat straightening, a process used to repair a damaged underpass girder.

The repair site was the Lees Avenue underpass on Highway 417, in the City of Ottawa, where a steel support girder was severely damaged in the summer of 2010 by an overheight vehicle carrying a backhoe.

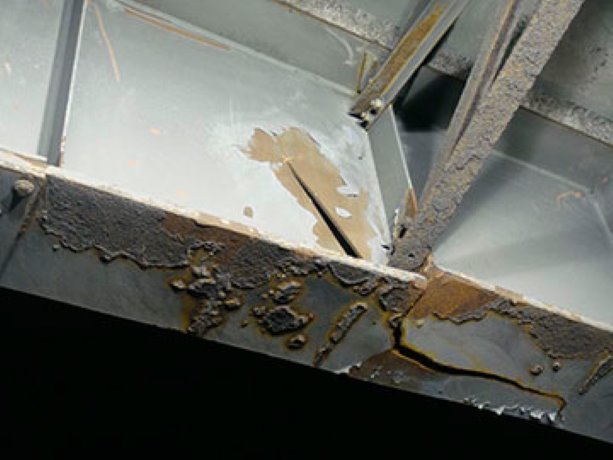

The curved, horizontal girder suffered a fracture crack of about six centimetres through the web and completely through the bottom flange. The mismatch at each side of the crack measured about 50 mm across the bottom flange.

After securing the site and temporarily closing one lane of the highway, engineers determined that the road could be re-opened.

“We determined that the safety of the public would not be threatened by falling debris or any further sagging of the girder,” says Jerry Wang, a structural engineer at MTO. “The remaining support structure was strong enough that we needed only to shift the traffic slightly towards the interior girders and kept the Lees Avenue underpass open to vehicular traffic.”

Only the pedestrian portion of the underpass near the southbound lane was closed until repairs could be completed. Routine patrols continued to inspect the overpass.

“Our analysis indicated that if we replaced the damaged girder, we would have to take out part of the bridge and restrict traffic for eight months to a year, with a total cost of about $2.3 million, including the cost of road closures and traffic detours,” says Quazi Islam, head, Engineering, Structural Section at MTO.

“We’d seen a demonstration of heat straightening which promised to repair a girder without depleting its strength. We realized that a repair by a heat straightening technique involving short partial night closures could be planned for this site to repair the cracked girder without affecting traffic for more than eight months.

“ If it worked, it would be a win for MTO and any other Canadian provinces that might want to apply this repair technique. The only risk was that if it didn’t work, we would be back at square one, replacing the girder.”

The heat straightening project was carried out using a team of ministry experts and others from across North America under guidelines published by the U.S. Federal Highway Administration. The design consultant, McCormick Rankin Corporation, worked with MTO’s Engineering Office to determine the scope of the procedures. MTO also retained Dr. Richard Avent and Gerry Hill, American straightening experts. The general contractor was Clearwater of Ajax, Ont.

“The design of the procedure was the most important aspect of the job,” says Islam. “This is essentially a high-tech application of blacksmithing techniques, with heat and applied force reorienting the elements of the metal in such a way that it shapes itself to your design.”

While the metal is heated, the girder is pulled into shape using a series of heating and cooling cycles with jacks, chains and turnbuckles installed to prevent the structure from deforming in the wrong direction and to maintain structural integrity.

“The project can only be successfully completed by a combination of just the right jacking force combined with heating and cooling cycles,” says Wang, who remained at the site for several nights in December 2010 to make in-the-field decisions regarding the procedure. “You need expert experience to determine the exact required colour of the heated steel and the colour of the flame.

“You also need to perform the technique gradually in stages, because overdoing the process can further crack the metal. The process is so gradual that you can’t see any movement with the naked eye. It took five nights to get the girder to move 15 mm.”

Once the girder was re-oriented, the original cracks were strengthened with the addition of bolted-on metal cover plates.

“We inspected the project to ensure the girder and welding between the flanges retained optimum strength, and that they were oriented to plumb,” says Islam. “The crack is now repaired in such a way that the girder is operating at full strength.”

Total cost of the repair, including traffic management: $870,000. Total repair time: seven days.

“As with all MTO bridges, this one is also monitored routinely by highway patrol and inspected biennially by bridge inspectors,” says Islam. “The repair continues to perform to specifications and we now have a new tool in MTO’s repair arsenal.”

1/2

Photo:

Recent Comments

comments for this post are closed