When the project is as big as the Bruce Power nuclear reactor refurbishments, it’s measured in 10s of billions of dollars and decades of work.

Building on preliminary upgrades which began in 2016, Bruce Power is inching closer to refurbishing Unit 6 and expects to wrap it up in 2024, one step closer to the total upgrades scheduled for mid-2060.

It’s a $13 billion journey to refurbish all eight nuclear reactors and critical work since the original Bruce A units were started back in 1969 while Unit 6 went operational in 1978 and the refurbishment cost is $2.185 billion.

Work at Unit 6 is well underway, says spokesman John Peevers, and is so far on track as far as cost and schedule which is important news since Bruce provides about one-third of Ontario power at any given time, half of the 60 per cent of overall nuclear power feeding the province.

“However, COVID-19 may impact on our overall cost and schedule contingency,” he notes. “In March 2020, we had to temporarily pause the project. At the time, the Unit 6 Major Component Replacement (MCR) Program was ahead of schedule but we had to scale back and limit work to essential tasks related to plant safety and system integrity for several weeks.”

Work restarted in May 2020 with the safety measures common to all construction sites during the pandemic.

“Still, there were challenges our team faced as we got used to a new way of working and living,” he says. “We realized the amenities we built to support our trades were no longer sufficient given that everyone was required to physically distance. Our lunchrooms weren’t large enough; the change rooms no longer worked. We developed a Covid Response Team that looked at issues like this and found solutions to these unexpected problems. We built a tented structure for Covid testing, converted unused space into lunchrooms, and repurposed rooms to turn them into change rooms for our workers.”

Supply chain issues which have plagued manufacturing and construction alike haven’t manifested at Bruce, he says.

“Because of long lead times in securing nuclear components and the necessary careful planning of a project of this magnitude, we have not faced any major challenges with material or components,” he says. “All the manufactured components for the Unit 6 MCR were completed by early 2021 and our supply chain partners including Laker Energy, BWXT, Cameco, Nu-tech, Brotech, BCI and Niagara Energy as well as our employees, contractors and trade unions deserve a ton of credit for keeping the project on track.”

It’s also a strong buy-Canadian project with 90 per cent of investment in manufactured goods and services coming from 480 companies in Ontario and other provinces.

Skilled labour has also required some outside-the-box thinking with trades hired from across the country to meet demand.

“We’ve hired skilled trades from other areas of the country like Quebec and the Maritimes to work during busier times in the project and we also created a Boilermaker Helper Program which was established in 2019 and executed in 2020 to support MCR’s high demand for trades people,” he says.

“Approximately 80 people joined that program and assisted with our removal series of work. We’re targeting 150 individuals for our Boilermaker Helper Program on the next refurbishment which begins in 2023.”

The project scope through 2064 is such that it could see generations of workers come and go and planning for that demand starts now.

“We have over a decade of refurbishments ahead of us, we’re actively working to help fill the skilled trades gap in conjunction with unions and schools,” Peevers says. “For example, we’ve been working with Georgian College and the Canadian Union of Skilled Workers (CUSW) since 2019 on our Pre-Apprenticeship Program, which allows youth to try out various apprenticeships before selecting one to pursue.”

The average number of trades on site is as many as 3,500 trades, he says, but in May of this year, they had 6,500 including both trades people and office workers like project managers and administrative staff.

To handle the crowd they build a new Bruce B Administrative building with change rooms, office space, meeting rooms and lunchrooms, but social distancing put limitations on how many people the facility could accommodate.

So, they created more temporary space by using trailers, a tension fabric building, and even converted a breezeway into a lunchroom.

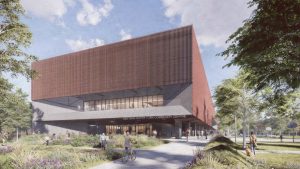

Offsite, they built the MCR Training Facility in Kincardine, Ont. which is split between offices and a training area where skilled trade workers prepare for executing work inside the reactor vault.

Peevers says the 129,000-square-foot facility houses up to 500 people and offers unique training tools that will allow skilled trades people to practice executing the highly technical series of work. As one group transitions to the station to perform work, another group would transition into the training facility to begin practicing for the next series of work.

Bruce Power operates with six of the eight units online. The oldest units, one and two, were shut down in 1995 and then restarted in 2012 anticipating refurbishments of the other units.

Peevers says the plan is for all eight units to be online as electricity demand soars with increased use of electric vehicles and appliances.

Recent Comments

comments for this post are closed