The Middle East has always been a high temperature zone.

However, Europe and North America, long considered moderate, have experienced higher temperatures over past summers, a trend projected to continue. The increased demand for air-conditioning is adding more energy loads onto power grids and with that added costs for building operators.

That’s why TermoDeck®, a Swedish building technology that has been used effectively in the Middle East for decades, is finding interest in North America.

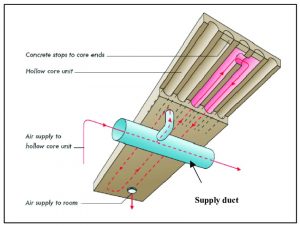

As temperatures increase during the day, TermoDeck stores surplus heat in its hollow core slabs. That heat is dissipated at night as the slabs cool, either due to reductions in the ambient temperature or using conventional chillers, with supply fans running 24/7. The net result is energy loads can be reduced significantly compared with conventional technologies, the company says. In winter, the process is reversed to add heat to the interior as required.

Comparing TermoDeck to conventional HVAC systems, a report carried out in the Middle East by ASA Consulting showed TermoDeck could save around 40 per cent in running costs, while another independent report suggested the TermoDeck system also carries a lower capital cost. It’s achievement of high performance alongside low energy usage has resulted in its use in “green” buildings built to BREEAM, LEED and PassivHaus standards.

TermoDeck says the highest energy savings are achieved in cooling mode in commercial and institutional buildings. Immediate cooling savings of 35 to 50 per cent over 24 hours and up to 90 per cent during peaks have been measured.

Structures designed to use pre-stressed hollow core floor slabs are perfect candidates for TermoDeck, the company says. Beyond the energy savings, the system allows for a more flexible interior layout since there is neither any duct work nor any false ceilings. That also allows interior layouts to be shifted easily as needs change. Electrical services and sprinklers can be carried within one of TermoDeck’s three core layers.

TermoDeck has been used on buildings over 30 storeys and those with high ceiling areas. In these instances, the system is used in conjunction with what is called displacement ventilation. Displacement ventilation uses a slow-moving stream of fresh air from the floor to displace the waste air, which is forced to the ceiling and then out of the room through exhaust panels.

Individual room control of supply air is part of the TermoDeck thermal modelling commissioning process.

“Airflow can be regulated by using dampers in rooms with temporary higher internal heat gains such as large lecture theatres, conference rooms and seminar rooms.”

The company has also developed a system called Switch Flow to provide instant cooling.

“By pushing a button (or driven via thermostat) the cooled air will only pass through one core and therefore it will enter the room at low temperature. Switch Flow doesn’t increase the energy consumption as the cooling is just delivered directly to the room rather than via the slab.”

Keeping building walls cool is also the subject of recent investigation.

Researchers have found a zigzagged structural wall consisting of an Infrared (IR) emissive surface facing the sky and an IR reflective surface facing the ground can passively reduce wall temperatures.

“Radiative cooling (RC) has been an attractive electricity-free approach to reducing the energy consumption of buildings,” they write in their report.

While previous RC strategies have focussed primarily on roofs, with heat reductions of up to 20 per cent, only limited attention has been paid to vertical walls.

Yet, heat reflected from the ground, such as concrete surfaces in urban areas, can be extremely high. Using corrugated materials and a zigzag profile on vertical surfaces appears to resolve this.

The researchers report in building simulations when the ground was approximately 56 C, their proposed wall design led to a daily average temperature reductions up to 3.1 C compared to conventional walls coated with RC materials. This corresponds to a relative cooling power of 67 W/m2 compared to the control wall.

Commercial application seems to be the next logical step.

John Bleasby is a freelance writer. Send comments and Inside Innovation column ideas to editor@dailycommercialnews.com.

Recent Comments