A departure from how buildings have traditionally been designed and constructed is vital to meeting low carbon targets.

Reaching those goals, however, won’t happen without transformative changes in training and education.

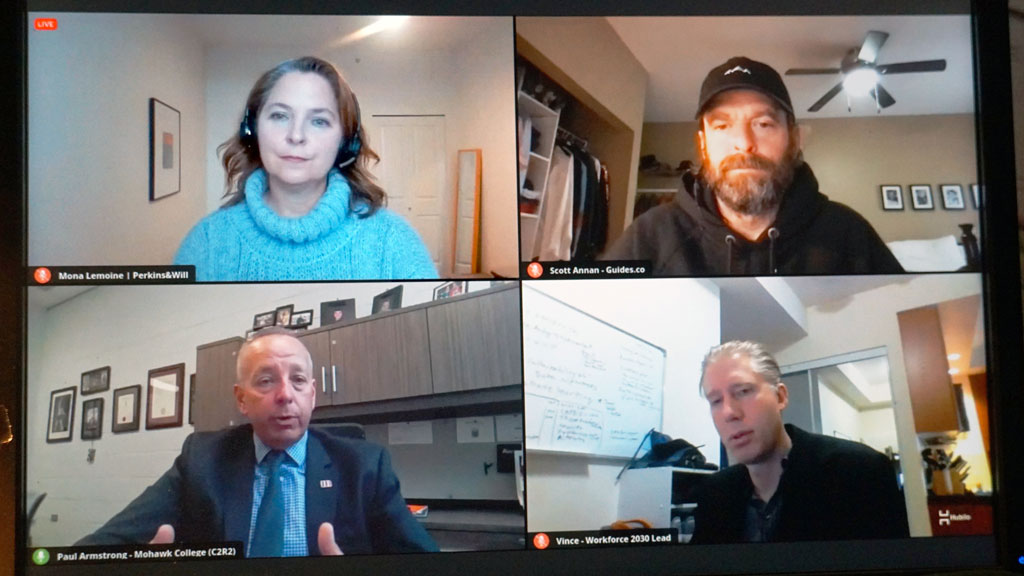

That is one of the takeaways from Fast Tracking Low Carbon Skills, a webinar presented at the Canada Green Building Council’s Building Lasting Change conference.

Paul Armstrong, chief operating officer of Mohawk College, said while “upskilling” is vital in the industry, training methods need to be packaged and delivered in a flexible manner for workers and employers. “Employers don’t have the luxury of letting people go for a year, six months, a month or a week even.”

Formal educators can’t worry about the fact people will be accessing education in many different ways, said Armstrong.

He is the co-chair of the Canadian Colleges for Resilient Recovery (C2R2) Steering Group, a 15-partner group examining how to quickly develop thousands of training and research opportunities to meet industry needs.

Armstrong said there has to be a transition from the “lockstep model” of learning delivery, education and training in silos, to an integrated model where education and workplace experience occur simultaneously. It’s an approach C2R2 is working on.

Scott Annan, founder of Guides.co, agreed, telling the audience that colleges and universities need to integrate learning into work streams so workers learn new skills as they do them. He sees upskilling and relearning becoming as big a market as the traditional college diploma or university degree.

Panellist Mona Lemoine, senior sustainable design specialist with Perkins&Will, stressed the importance of not only reducing operational carbon in the building industry but also embodied carbon in building materials. The firm aims to have all of its designers apply what has been learned from the firm’s embodied carbon working group to their practice in the field.

While Perkins&Will has learned much about embodied carbon, there is still work ahead for the firm and others.

Using tools to measure wall assemblies and various other materials and finishes is critical, said Lemoine, who is the chair of the regenerative environments committee of the Royal Architectural Institute of Canada.

Lemoine told the panel it should be mandatory that the documentation of materials pertaining to embodied carbon is transparent to the users.

“Manufacturers can find a way to absorb the cost in the product. It is a direction our industry needs to go.”

Annan, who said it is paramount that construction workers accept new technologies, added the pandemic has been a catalyst to technological integration in the workplace.

“We are seeing some major advances in digital literacy.”

He added the competition among builders on contract prices shouldn’t be placed above “a new way of building. Getting there is going to require large-scale collaboration…true integration and access to knowledge as it evolves.”

Annan told the webinar while the government’s role is critical in advancing education, industry has to come up “with visionary new products. The idea of selling the same (buildings) with less carbon is not sellable to me.”

A key draw for the new generation to an industry on the cusp of major skilled shortages is in part the use of high tech innovation in the design and construction process.

“These are not the homes of your grandparents but whole new homes where there is integrated technology.

“It’s an exciting time and I think there is a ton of opportunities to come.”

Armstrong said builders and construction groups/associations need to reach out to or be a part of college advisory groups to inform training and education leaders on new building and design directions.

Lemoine told the webinar an important innovation will happen as architects partner with industry to design buildings with guides or manuals on how to disassemble them for reuse at end of life.

Recent Comments

comments for this post are closed