In a fabricating shop in Burlington, Ont. a small group of stonecutters and carvers are doing their part in the restoration of a church at a venerable American university.

Old World Stone Limited is designing and fabricating the Tracery stone for 30 replacement windows at Packer Memorial, an historic Gothic Revival church on the campus of Lehigh University in Bethlehem, Pa., a private institution founded in 1865.

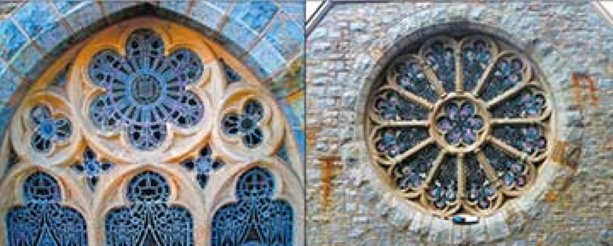

Tracery is the ornamental stone in windows, primarily Gothic and Medieval ones, says Laurie Wells, sales and marketing vice-president for Old World Stone, a supplier of dimensional cut limestone and sandstone.

“There are only a handful of firms in North America which do this kind of work.”

When Packer Memorial was built in 1885, a weaker layer of sandstone was used and that, along with the construction techniques, has contributed to the stone deterioration.

“The stone was installed vertically, instead of horizontally.”

Over the years, the layers of sedimentary stone delaminated and the windows were repaired with patching and paint, she says.

“This failed very quickly and the process of repair was repeated.”

A few years ago the university was about to embark on yet another patch and paint operation when the on-site mason contacted Old World Stone for a consultation.

“The deterioration had reached the point stone pieces were falling off and there were concerns this would damage the stain glass windows,” says Wells.

As the company was able to supply a similar stone in a strong layer, it was given the contract to design and supply the stone pieces for 30 windows over a five-year, five-phase period. The replacement stone is Wallace sandstone from a Nova Scotia quarry. It is a process which required Wells to visit the university to measure the existing stone pieces, with the assistance of the masonry contractor. The stained glass contractor also provided templates of the glass after samples were removed.

The project is now in its second phase and involves the design and supply of 30 pieces of stone — in three unique shapes — for the church’s rose window, as well as for two transept windows, three altar windows, and a one-organ chamber window.

Preparation for this phase began in 2012 with the ordering of stone from the Nova Scotia quarry. Wells completed field dimensioning in the fall of 2013, with the drafting beginning this past December. A team of five cutters and three stone cutters commenced production in January. A variety of saws are used to profile and rout the rough shapes, while the detailed work is done by hand with the use of air hammers and grinders, says Wells. The stone will be delivered in stages to suit this year’s construction schedule which won’t begin until after commencement ceremonies are completed.

“Site storage is extremely limited, so we may only be able to send one window at a time.”

With most of the windows, the old stone can be removed in a day. But installing the new pieces can take anywhere from three to five days and then the glazier has to reinsert the glass which can take up to a week, she says.

An Old World Stone representative is not required on site, says Wells, explaining the company uses a combination of field visits, site measurements and the sharing of AutoCad drawings with masons and glaziers on its projects.

Recent Comments

comments for this post are closed