Residents walking near a large public park at the bottom of the Niagara Escarpment in the west part of Hamilton, Ont. may be able to see the surface work, but they’re probably only vaguely aware of the beehive of construction activity taking place a few hundred metres below.

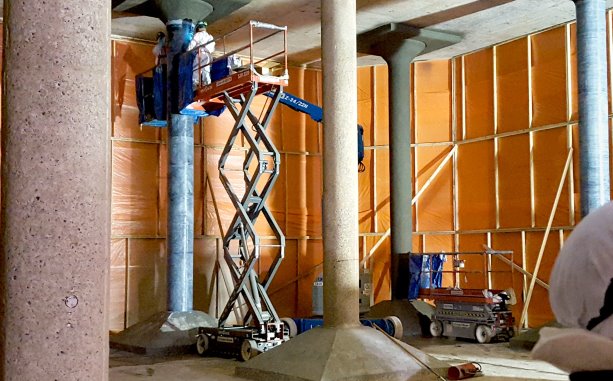

As part of a major list of exterior and interior improvements, including the rehabilitation of the existing roof and a new precast concrete roof on top, 76 concrete columns supporting the roof of the Hillcrest Reservoir are being structurally strengthened and waterproofed through a process known as the SikaWrap system.

At the heart of that system are carbon fibre reinforcing polymer (CFRP) sheets which are precision cut on site and wrapped around the 0.56-metre-thick columns.

Newman Brothers Ltd. is the general contractor and WSP Canada Inc. is the consultant for the project, which is being carried out in the reservoir’s east chamber. Rehabilitation of the west chamber was undertaken a few years ago.

Overlaid with the grass-covered overburden, the circa 1930 facility is a large underground facility containing potable water and is the oldest operational water storage facility within the city.

"It’s probably two football fields in length and half a football ball field in width," says Sika Canada technical sales representative Bruce Hudson in underscoring the project’s complexity and scale.

Mississauga-based Sika is the manufacturer of SikaWrap, which is now being applied by Vector Corrosion Technologies, a specialty concrete restoration firm and a licensed applicator.

Because of the roof rehabilitation, which will add weight, the columns have to be strengthened.

There has also been some concrete spalling, says Hudson.

An expensive and difficult concrete reinforcement of the columns would have been required if the SikaWrap system hadn’t been utilized, says Hudson.

The project is still a challenging task involving the application of a number of different layers or coatings that have to be applied within a certain time window of each other, says Vector project manager William Marshall.

First step, however, was draining the reservoir, then a 40,000-pound-per-square-inch power wash cleaning of the columns and some concrete repairs by other subcontractors before Vector came on site in December.

The Sika system is installed by first applying the levelling layer, which can be either trowelled or sprayed on.

After a minimum 24-hour curing period, an impregnating resin is then trowelled onto the columns. Immediately afterwards, the CFRP sheets are wrapped around the columns into the uncured epoxy and then rolled with a laminate roller to force the epoxy through the fibres and remove any trapped air.

A final two-step application of an epoxy waterproofing completes the process. The first coat is a light green colour and the second is a medium grey. The same system is also being applied to the concrete walls.

"This (the different colours) is a quality assurance measure and visible verification to the engineers that the two coats have actually been applied," he explains.

It’s also a long-term safeguard warning. If, at some point in the future, green patches start to show through, reservoir operating-staff personnel will know it’s time to reapply the second coating, he says.

With all the work going on, the timing of the application of the layers can vary from column to column. To keep the project manageable, the reservoir has been divided into six zones.

"We completely finish one zone before moving on to the next one," Marshall adds.

Timing and scheduling aren’t the only challenges. Relative humidity, concrete surface temperature and ambient temperature have to be controlled and monitored to adhere to the manufacturer’s environmental restrictions and guidelines. To meet those restrictions, a one-million-BTU heater is always operating and a second one is kept on standby in case the first one fails, he says.

"This is a confined space. Our workers’ respiratory equipment is checked each morning before they enter the site and periodically during the day," says Marshall, in highlighting the safety considerations.

Timetable for the project’s completion is May, he says.

Recent Comments

comments for this post are closed