Defying stereotypes, a prefabricated steel building at the University of Toronto — Mississauga (UTM) will be anything but “a plain Jane building with repetitive elements.”

“This really becomes a demonstration of the potential of modular buildings to be able to render exquisite architecture,” says Carl Blanchaer, a design principal with WZMH Architects, the project architect for the two-storey building that will house UTM’s campus police services, hospitality and retail operations on a busy pedestrian artery of the university.

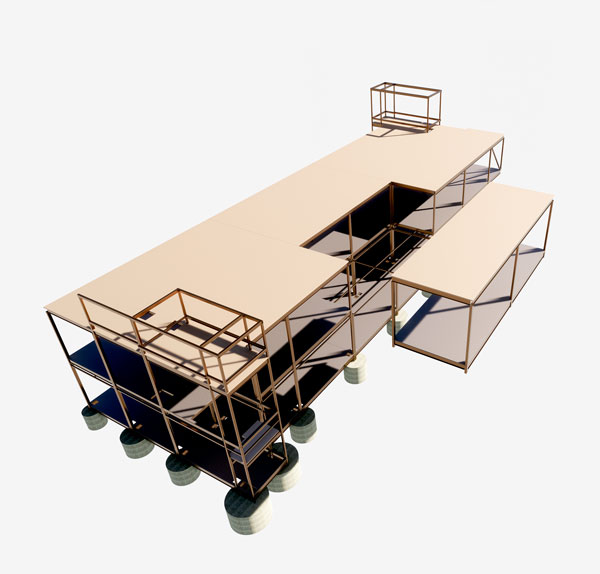

“The campus is a collection of very beautiful buildings done by some of the country’s best architects, so we have to make sure this is of the same level of quality. We looked at this building as a series of shifting volumes,” says Blanchaer.

Prominent will be a cantilevered section on the second floor.

Different metal cladding materials will be used from floor to floor.

Speed and quality of construction were factors in the selection of the building’s lightweight prefabricated steel structure.

Minimizing construction disruptions is paramount, he says, because “this is on a significant exterior pedestrian spine. It is one of the gateways to the campus.”

The structure will consist of a steel sandwich plate system (SPS), which was chosen over a conventional steel deck with concrete slab design because it is “light and very modular,” says Zenon Radewych, WZMH’s managing principal. “It allows us to build all the partitions in a plant.”

At only 1.5 inches thick, the SPS floor is light (concrete floors are usually up to eight inches thick) allowing for thinner supporting beams, columns and a smaller concrete foundation.

The latter is important because “we’ve been dealing with some bad soil conditions,” says Sobhy Masoud, a structural design lead with Stephenson Engineering, the structural consultant.

Masoud adds the lightweight system is optimal for seismic loading requirements.

“It’s a very stiff system that takes out all vibration issues as well.”

Another benefit to the prefab job is that it allows the assembly team to work closely with WZMH and Stephenson.

The steel prefabricated modules will be designed for ease of transit to the site without special transportation permits, adds Radewych.

Each floor will be made up of 12 steel modules.

“The goal is to reduce the amount of work and disruption onsite,” says Radewych.

The architect says WZMH was introduced to SPS by Stephenson about five years ago. It was seen as a viable lightweight system to add floors to existing buildings.

“There are a lot of projects across North America and in Europe that have used it,” says Radewych.

Furthermore, says Masoud, SPS “is getting a lot of attention” from contractors.

Radewych says among the first design proposals reviewed for the project was one using structural wood but the SPS was selected because it allows for “prominent cantilevers” and “certain extensions of roofs.”

The structure is expected to go to tender in November.

It will take about four-and-a-half months to prefabricate modules in the shop. Site delivery is proposed for next March with assembly completion slated for the end of April, says Azin Omidi, a project manager with WZMH.

Blanchaer says moving forward WZMH sees prefabricated design as “an alternative means of how you build a building. It doesn’t have to be two-dimensional.”

“If you think of a university campus as a place for experimentation and exploration, then that is what this project is,” he explains.

He says at 820 square metres, the new campus addition is small, “but it is a very important building.”

Recent Comments