Designed to achieve LEED Platinum and intended to offer a wide range of film, media and performance facilities, the Cultural Hub Complex under construction at Humber College’s Lakeshore campus in Toronto is being heralded by the college as a project that will transform the campus, “into a destination for arts and culture.”

It’s also a project with several challenges, not the least of which is a fast-paced schedule.

The first phase of this two-phase undertaking involves the construction of what might be described as a long, skinny structure that will house amenities such as a 150-seat music performance hall, a gymnasium, classrooms, faculty offices, a cafeteria, ensemble rooms, a 320-bed student residence and a dining hall that will be connected to an existing residence to the north via a steel bridge.

Construction started in the fall of 2020 and the Integrated Project Delivery (IPD) partners responsible for delivery have set a spring 2023 completion date.

Those partners include the college, Diamond Schmitt Architects, Entuitive Consulting Engineers, EllisDon, steel fabricator/erector M&G Steel Limited, mass timber fabricator Kalesnikoff, mass timber erector Brite Millwork Ltd. Inc. and concrete trade contractor Alliance Verdi.

“IPD is a project delivery model that demands deep collaboration and communication from the fully engaged partner team. IPD challenges typical design and construction processes to be more transparent, collaborative and to work together toward one common goal: creating a successful project,” says Diamond Schmitt associate Dale McDowell.

Schematic design started in 2018 with the same design consultant team and then transitioned into an IPD project in the fall of 2019, she says.

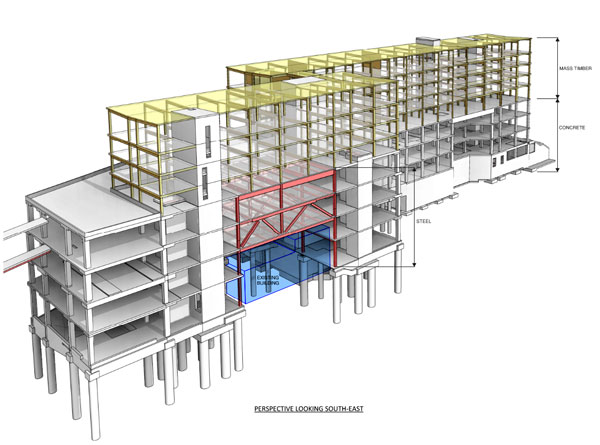

Being built with a mix of steel, mass timber and concrete, the first phase complex is also a project with severe site constraints and those restrictions were the catalyst for what the IPD project team partners describe as steel “cage” or a “box within a box.”

The facility had to be carefully positioned between the existing residence to the north, a library to the south, and a City of Toronto waterline easement to the east. But that wasn’t the only hurdle that had to be overcome, says McDowell.

Adding to the complexity was the college’s desire to retain a professional and educational state-of-the-art studio, which is considered a world-class facility.

“It was deemed essential to maintain the recording studio even though it (the retention) created incredible project constraints,” says McDowell, explaining the studio is very close to the city easement on the east side.

While the studio will be eventually incorporated into the Phase 1 building, the issue of noise and vibration from the construction penetrating the studio was a paramount concern.

“The best way to ensure acoustical separation was to have separate buildings,” says McDowell on the decision to erect a prefabricated five-storey-high, 20-metre-long-by-20-metre-wide steel enclosure that will be built up to and over the studio.

Erection of the cage by steel fabricator/erector M&G Steel Limited is scheduled to start Oct. 4 and take approximately three to four weeks to complete.

During that erection timeline the studio will be completely closed and then only opened during non-construction hours until the first phase is completed, she says.

To be comprised of steel columns around the perimeter, two 4.3-metre-deep, 17-tonne trusses between levels three and four above the roof of the studio and floor beams above the trusses, the cage will support two floors of academic space and the mass timber four-storey residence above, says M&G Steel project manager Chris Adach. The trusses will transfer the load of the student residence tower to steel columns on the north and south sides.“The erection of the box is not a straight forward endeavour.”

After the truss pieces are trucked to the site, they will be laid out in a truss configuration on the ground floor slab, bolted together, hoisted into place by a 350-tonne crane, and tied into the three-storey columns and braced for safety, he says.

Although the trusses represent the “dramatic aspect of the erection plan,” there will be heavy W1000 girders at level five which will require careful execution prior to the installation of a metal floor deck. The girders will serve as the support points for the timber columns of the residential floors above, says Adach.

Mass timber was selected for the residence because it aligned with project goals for net-zero carbon building and LEED Platinum, as well as speed of erection on site, McDowell points out.

Touching on the diverse uses of building materials in other areas of the complex, she says open web steel joists will be used for the roof of the gymnasium because of its large spans.

An academic podium, which will include the dining area and a drum studio, will be a concrete structure, she says.

Construction of Phase 2, which includes facilities such as a large performance hall and film studios, will commence in late summer or early fall 2022 and be completed in 2025. It will most likely be a predominantly steel structure due to the long spans in the performance hall, the film studios and a number of other areas, says the architect.

Recent Comments