Identifying treated wood uses for buildings required under the Canadian Standards Association (CSA) in the National Building Code was among the salient issues raised at a webinar recently hosted by Wood WORKS!, a Canadian Wood Council program.

Speaker Craig Wilson, who was partly responsible for developing the “use category system” for treated wood — the basis of the CSA requirements today — said specifying treated wood for non-residential applications falls under three main categories: wood species and size; type of preservative used; and the wood’s specific use.

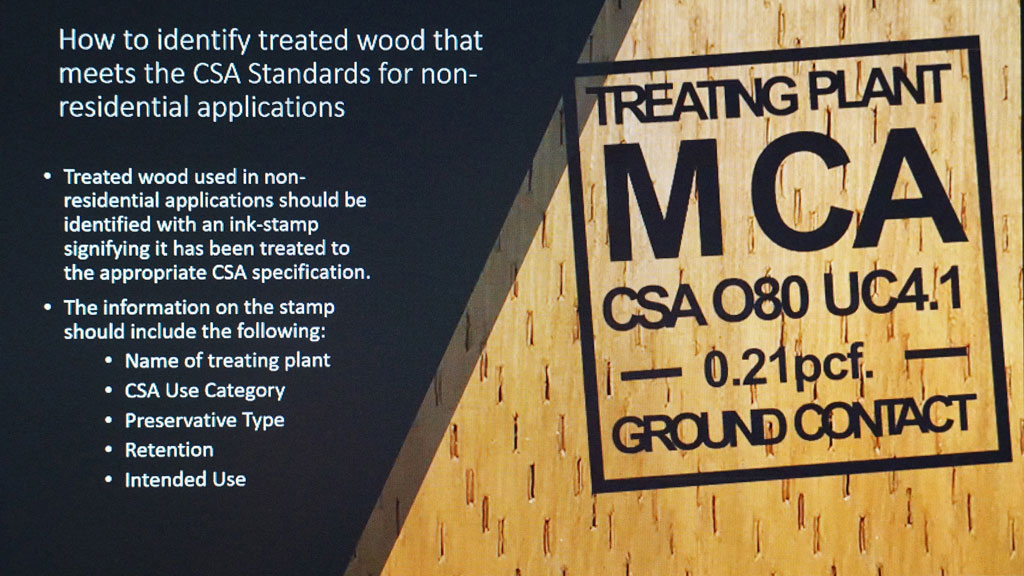

Wilson is vice-president of technical services at Timber Specialties Ltd., which provides preservatives and technical assistance to the Canadian wood preservation industry. He told the webinar audience that treatment specifications should be identified either through documentation or a stamp on the lumber provided by the plant to indicate that the treatment has met penetration and retention testing specs and the product’s specific use.

He advised the audience to use only treated wood materials from certified plants.

At consumer building centres almost every piece of wood has an end tag identifying the use and preservative applied, but it only meets the CSA-use category if it is indicated on the label, he pointed out, adding wood for non-residential applications is not typically stocked at retail lumber centres.

Among the considerations for specifying treated wood in non-residential applications is its grade, its moisture content and the species type, the latter being the top selection priority, he said.

Canadian wood species are generally “refractory” (difficult to treat) primarily because they often have a shallow sapwood band and a nearly impermeable heartwood.

“If you are looking at maximum durability, look for the most treatable species (typically red pine in Eastern Canada).”

He added true Fir wood (not Douglas fir) is next on the most treatable list followed by hemlock. Spruce should be avoided when maximum treatment is required and Douglas fir is difficult to treat with waterborne preservatives.

The only way of meeting wood treatment for structural or ground contact applications is through mechanical incising, a process of pressing sharp teeth into all sides of the wood to ensure full penetration.

“If it is not incised it does not meet the building code…the CSA standard.”

Ideally, any machining (cutting or drilling, for example) should be done prior to wood treatment but when that is not possible, Wilson said it is important to apply two coats of copper naphthenate to field cuts and bore holes.

While glulam has specific treatment requirements covered under the CSA for the product during and after assembly, there are no CSA specs for cross-laminated timber or other engineered wood products, he said.

Recent Comments

comments for this post are closed