As factory-built components of multi-storey structures become more mainstream, those in the sector are looking to the horizon of Artificial Intelligence (AI) and robotics.

Factories are already using automation at every turn to create wall slabs and floors, which are then shipped on a flatbed truck to the jobsite to be hoisted into place.

However, custom-details and features are difficult to program into the production run because the economy of scale that makes automation economically efficient requires a certain level of consistency.

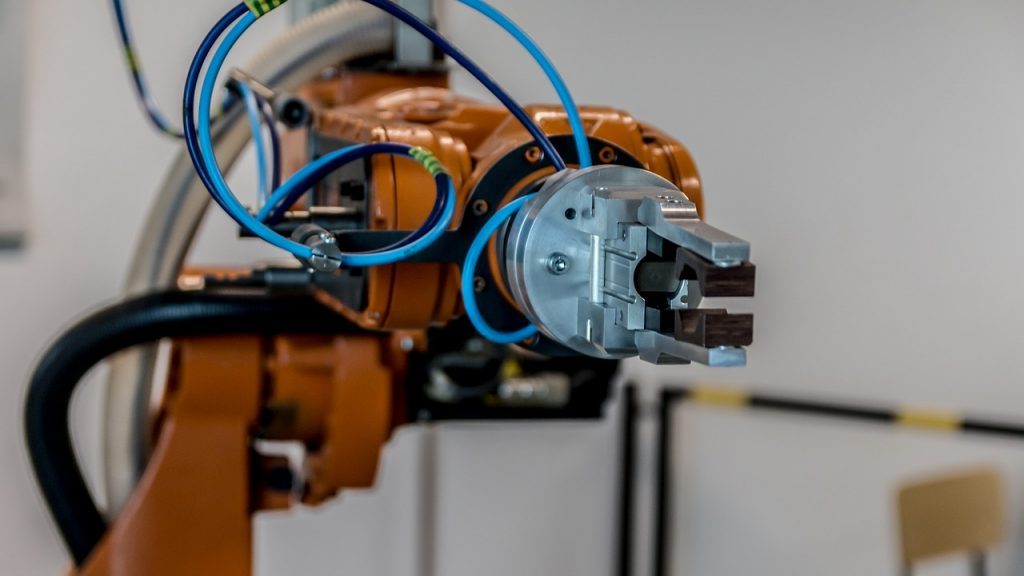

Technology, however, never sleeps and ETH Zurich, an incubator for construction materials and technologies is developing a robotic system that can pick, cut, join and assemble sections of complicated designs in a factory environment.

Using AI and complex hydraulics and controls, these robotic arms literally build a structure stick by stick, readjusting its movements as the structure takes shape within the assembly zone so as not to crash into what is now standing there.

Watching the prototype machine is like a ballet of engineering and it’s capable of producing some sophisticated structures from complex designs. It’s the kind of innovation that fascinates Tad Putyra, founder of Home Technology and president and COO of Low Rise at Great Gulf.

Home Technology knocks out floor and wall panels with laser-guided precision from its 110,000-square-foot factory near Toronto’s Pearson airport and is the biggest of its kind in North America.

“I’m lucky, because this is both my hobby and my work,” he jokes. “This is definitely a prototype of something we are going to see and are seeing already in some cases.”

While the robotics ETH Zurich is developing are for one-off types of structures and aren’t practical for mass production, they do represent the future.

“In mass production, say for a condo with 600 units, that’s mass,” he says. “And some of these robotics are already deployed in factories making houses in Europe. They’re not standalone but they are more auxiliary to the main equipment.”

Still, he says, they are on the horizon.

“For one, they cut labour costs,” he says. “They cut down on repetitive strain injuries, doing the same thing over and over. That’s one area robotics is helping to resolve.”

Robotic arms are common place now in automotive manufacturing and that has helped drive the technological sophistication while pushing the price of ownership down.

“Robotics are more standardized and much more reliable than ever,” he says. “They are also low maintenance and they can fit our needs better.”

Construction factories in Germany and Sweden are already incorporating robotic arms into their work flow, he says.

Randek in Sweden has launched their Zerolabor Robotic System which takes standard automation up to the next level. Driven by CAD files, it picks and handles the sheets, fastens them, cuts out an opening, marks the slabs with inkjet and even straightens studs before nailing.

Other components like roofing are getting a technology makeover too.

“In Finland, Trussmatic is making trusses using robotics,” Putyra says. “They are made to specific dimensions and ready to install.”

These technologies are coming to North America, he says, and they are being deployed. At first it will be the low hanging fruit but as time goes on more sophisticated designs and custom structural detailing will be easily incorporated into factory runs.

“To do the R&D in this area is expensive but we can see from other industries that these robotics are being deployed,” he says. “In furniture making, where the finish manufacturing is very important, robotics are working at an advanced level.”

Incorporating AI and sophisticated, programmable robotics into a factory floor for making houses, townhouses or mid-rise condominiums isn’t much of a stretch anymore, Putyra says.

“It doesn’t have to be cookie cutter, because it was factory built. It doesn’t have to be all the same. There has to be some standardization but I think hybrids will be possible and it’s going to be very interesting,” he says.

Recent Comments