Novice crane operators as well as those with years of experience can now practise the tricky art of making heavy tandem lifts in a safe and virtual environment thanks to an innovative new mobile crane simulator training pack developed by CM Labs, developer of Vortex simulators.

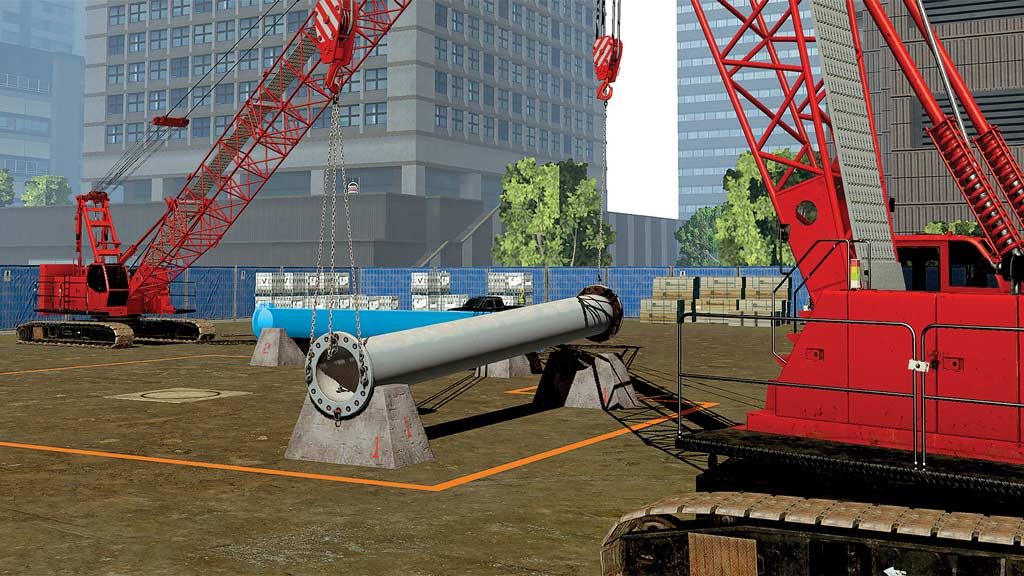

The training pack was developed by the Montreal-based company in response to stakeholder demand and features the industry’s only simulated mobile crane tandem lift exercise, along with a competency demonstration exercise that provides a sound, objective tool for employers to assess crane operator skills. The tandem lift exercise teaches the lead crane operator how to safely and efficiently manoeuvre a steel pipe load in tandem with a secondary crane, operated from another simulator connected on the network.

“Miscommunication is one of the most important contributors to accidents on the worksite,” explains David Clark, product marketing manager at CM Labs. “That’s why teamwork should be a centerpiece of any operator training.

“The mobile crane tandem-lift exercise teaches operators how to communicate for efficient and safe lifting operations. This type of team-based training can be expensive and difficult to reproduce in real-life but is safe and easy to set up with Vortex simulators.”

Tandem lifts are often conducted in the field, but it’s difficult to train apprentices on such manoeuvres because of the danger. The scenario will enable students to practise such exercises in a safe environment.

“In addition to the costs and logistical challenges that setting up the exercise represent, working in tandem multiplies the risks of accidents in the field,” explains Clark. “Operating the mobile crane in inappropriate ways can cause the equipment to tip and has important repercussions on both operators and their equipment.”

The training pack will allow trainees to practise without fear of injuring their co-workers or themselves, or damaging the equipment, he says. The tandem-lift feature can be deployed in multiple configurations, with operators working at any combination of CM Labs simulators. Collaborative learning can be further extended with CM Labs’ signal-person training station, which allows a trainee to guide the operation within a challenging virtual jobsite with power lines and jobsite personnel.

The training pack covers the entire lift process, from lift plans to controls familiarization to complex lifts, such as lifting steel structures, working in buildings, and working around power lines. It also allows trainers to fully evaluate operator readiness with an innovative assessment exercise. The exercise is the only simulation-based assessment tool to cover advanced lifting techniques, such as performing a blind lift, recovering from a load pendulum, girder lifts, and more.

It provides in-depth assessment capabilities and progressive learning exercises for training centres that train apprentice operators as part of their curriculum. Companies can use the simulation for every stage of their workforce development cycle, from operator assessment and training to cross-skilling.

The system tracks all operating metrics during training exercises and rolls them up into a single score that updates in real time. Some of the metrics tracked include time spent in pendulums, the amount of time it takes to complete a task, rough load handling, load or hook collisions, load dragging, time spent in alarm conditions and contact with power lines.

Organizations can customize the scoring system to take their most important operating criteria into consideration. This, in turn, gives instructors a benchmark for objectively assessing operators after every training session in order to meet training objectives more rapidly.

Clark says the training pack is a “complete training tool,” as it considers all types of scenarios in a lift. He notes that fatalities and injuries by electrocution are a major concern for construction companies and it’s therefore important that operators also be trained to work around power lines.

“While trainers can’t currently add in buildings, they can toggle power lines on or off for the worksite, making the exercise more challenging,” says Clark.

All the company’s training packs include technology with proprietary and patented algorithms validated by subject matter experts from John Deere, Manitowoc, the International Union of Operating Engineers, the Operating Engineers Training Institute of Ontario and other leading organizations.

The simulators are built on a high-fidelity, real-time physics engine and have technology that includes a mechanical engineering layer with multi-body constraints, transmission, tire models, cables, and other real-time simulation features that are unique on the market.

“That’s why it delivers the most transferable operator skills anywhere, outside of the real equipment,” says Clark.

CM Labs, which has more than 1,000 simulators in 30 countries, making it the largest simulator vendor in the market, has other projects in the works, he notes, to make simulation-based training as realistic and immersive as possible, while making sure that skills are transferable to the real equipment.

“We are always developing new equipment training packs and new hardware, continually investing in research and development, and exploring new technologies and ways of improving operator training,” he says.

Recent Comments