The past couple of years have highlighted the importance of a reliable procurement process for construction companies, but supply chain challenges have made it difficult. Between inconsistent supply and irregular operations, leaders have struggled to establish procurement processes that can guarantee materials and equipment are there when they are needed.

As a result, more construction business leaders are exploring the benefits of using a purchasing platform to augment existing procurement processes. This article will discuss the supply chain challenges that construction companies must overcome and share how a purchasing platform can help.

Procurement challenges faced by companies

According to Deloitte’s 2021 Global Chief Procurement Officer Survey, more than a third of suppliers haven’t met procurement requirements. Over half of surveyed CPOs state their key suppliers had diminished capabilities or financial problems.

Construction companies require a consistent supply of materials and equipment to achieve their goals.

Here are some challenges procurement managers face in construction companies:

- Supplier-side issues

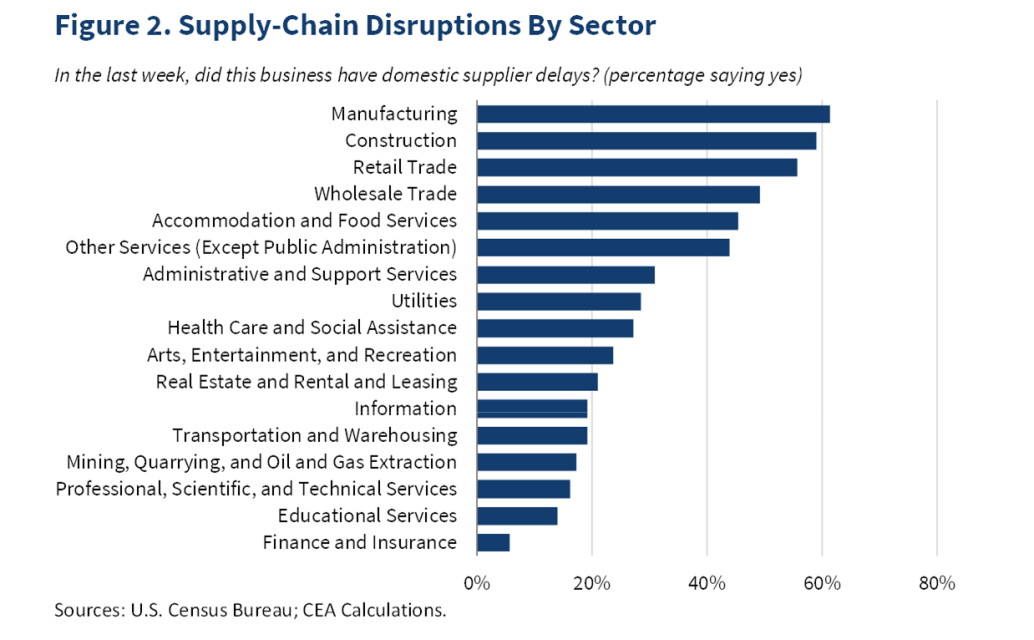

The pandemic disrupted supply chains, especially in sectors such as manufacturing and construction. Poor supplier management can disrupt even the best construction projects. When you can’t rely on your suppliers to deliver quality products on time, your schedule will be disrupted, leading to substantial monetary losses in delayed work, poor planning and more.

Procurement managers need to monitor suppliers to assess their performance, verify the quality of the supply and the reliability of delivery. This insight helps identify your best suppliers and improve your supply chain.

- Non-accurate route selection

Designing the best route to bring your supplies is critical to keep costs at bay and your project on time. Your suppliers need to provide the optimal route to prevent costly losses due to delays. The selected route needs to adjust to your business plan, considering the cost, quality, risk, financing and project constraints. - Shadow purchases

These are purchases made outside the company’s established procurement process. Because this spending is not controlled, it can produce issues such as duplicate purchases, poor tracking and loss of revenue. Rogue spending can be reduced by implementing an expense tracking system to streamline spending and prevent non-approved purchases. - Cost management issues

Staying within the budget is one of the primary objectives for construction companies. This needs a proactive approach in finding ways to reduce costs. With the price of materials recently increasing, it is more important than ever to implement solutions that help control spending and realize savings. - Lack of transparency

Manual tracking methods like spreadsheets were useful when they started helping organize data. But these days, the massive amount of data produced in any construction project makes it almost impossible to handle using manual processes.Locating information across multiple spreadsheets and stakeholders can be a challenging and time-consuming task, and having data stored across disparate resources can bring a lack of transparency and security risks. Any mistake can result in inaccurate information that will affect your business.

Implementing an automated purchasing platform is one of the best ways to bring transparency to your construction process.

- Long procurement cycle

There are several causes of a long procurement cycle in construction, such as delays in preparing specification documents, estimates or the statement of work for projects. Poorly managed procurement documents can also cause human errors and delays, lengthening the procurement cycle. - Legacy or non-existent technology

Many construction companies start out managing their procurement processes manually. This may include using spreadsheets or multiple software packages for different tasks in the procurement process.However, when processes get more complex, using legacy systems can become an issue instead of a solution. Leveraging a solution specifically designed for construction projects can decrease costs and improve productivity.

- Inaccurate data

You can’t make robust procurement decisions without reliable data. Errors can cause inventory issues, cause management problems and ultimately affect your bottom line.

The benefits of using a purchasing platform

Construction purchasing platforms are software packages that enable construction companies to automate the procurement process from request for information to delivery. These solutions streamline processes and eliminate human errors. Here are some of the benefits of leveraging a purchasing platform:

- Mitigates procurement risks

After the pandemic, many procurement managers are looking for ways to mitigate future risks from suppliers and control costs.Automated procurement software can reduce risks, costs and procurement time. Leading purchasing platforms enable reliable sharing of documents and orders, reducing operational risks, inaccurate payments and unapproved purchases.

- Centralizes procurement functions

Procurement processes are not isolated, but involve multiple factors, procurement officers, vendors, financers, management, inventory managers and more. If each stakeholder has their own disparate system it creates data silos, impairing procurement processes.An automated purchasing platform centralizes procurement tasks, document sharing, and communications so all related data can be accessed from a central interface, simplifying data management.

- Improves supplier performance

We mentioned above the need to monitor and track suppliers’ performance to optimize the process. However, doing this manually is time-consuming, with the risk of falling into infrequent evaluations. Moreover, you may fail to identify poor-performing suppliers, impacting purchasing costs and times.A purchasing platform can collect and create reports based on accurate supplier data.

It gives procurement managers near real-time data and provides clear supplier profiles. As a result, you can detect good performers and identify purchase risks. This encourages suppliers to perform better.

- Streamlines invoicing and payment processes

One of the most time-consuming and complex tasks in procurement is matching invoices with the related purchase order.Manual processes can result in invoice delays, mistakes and duplicate payments. Purchasing automation eliminates these issues, reducing invoice processing times and increasing accuracy.

How to integrate a purchasing platform with existing procurement systems effectively

After you decide to purchase an automated platform, there are several factors to consider when choosing the best one for your business. One of the key aspects is the integration with your existing systems.

This can depend on the type of platform, the environment it is hosted on and the release model. You can choose cloud-based, hosted or hybrid platforms according to your organization’s environment.

Tom Stemm is the CEO/founder of Ryvit.com. Tom leads a team of integration developers, application enthusiasts, customer heroes and sales superstars on a mission to eliminate duplicate data entry and rampant data errors from the construction technology world.

Recent Comments