A Canadian company is working to create slipform concrete towers for wind turbines, to build taller towers to support bigger and more efficient blades.

A Canadian company is working to create slipform concrete towers for wind turbines, to build taller towers to support bigger and more efficient blades.

Towers of 100 metres or more can support larger turbines with rotors of greater diameter and reach, where winds blow stronger and more consistently.

This results in greater energy capture at competitive construction cost.

The technology was devised by FWS Technologies with head offices in Winnipeg.

It is called Slipform Concrete Wind Turbine Tower with Self-erecting Capability. The concrete towers are designed to rise up to 140 metres into the air, extending the height of the turbine to 50 to 60 metres beyond conventional steel towers.

Such a tower would measure about 10 metres in diameter at the base and about six metres at the top.

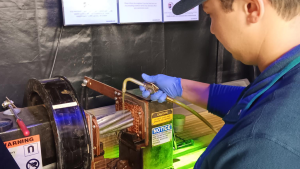

The base of the tower would contain a control room, electrical equipment and maintenance equipment.

Instead of using large mobile cranes to erect steel or sections made of other material, the turbine tower would use a slipform concrete pouring technique similar to that used to build the CN Tower.

The turbine, nacelle, generator and rotor assembly would be hoisted into place using a self-erecting electric gantry crane system, which rises on top of the tower as it’s erected. After assembly, the gantry system would be disassembled and lowered to the ground for re-use.

“We have a lot of experience in slipform concrete construction,” said George Depres, chief operating officer with FWS.

“We’ve built over 100 concrete structures for the agriculture industry in Western Canada and we are now into slipforming head frames for mining companies — essentially any project involving large monolithic concrete structures. Concrete offers high strength and stiffness and superior harmonic and vibration dampening characteristics for wind turbine tower construction.”

Taller towers may see energy gains of between five and 15 per cent over the life of the project, said Joseph Furgal, project development manager with FWS.

The taller towers can also support larger turbines producing five to six megawatts of electricity, two to three times the output of most current models.

Steel towers are not widely available from Canadian suppliers, which means tower components are often imported from Europe and Asia.

Slipform concrete towers, on the other hand, spur local construction activity and satisfy local content requirements, now frequently a qualifier for renewable energy projects in many jurisdictions.

Depres said inaccessible and remote locations are an ideal application for this technique, but that long-distance large crane rentals can add from $250,000 to $500,000 to the cost of erecting a wind turbine — if the cranes can be delivered at all.

By eliminating the cost of the crane and increasing the energy capture of the turbines, the company hopes to enhance commercial wind project viability.

In remote areas, one or two tall concrete towers can create a consistent local electricity supply, reducing dependence on traditional power sources already in place.

“A lot of the choice sites in the first wave of development have already been spoken for,” said Furgal.

“At these new heights, one of the big advantages is that second wave sites, previously considered unacceptable because of lack of consistent wind volumes, may now be economically viable.”

He said getting these components to a construction site is no longer a problem because there are no logistics barriers associated with shipping conventional tower components to site.

“We just need the formwork, a batch plant, rebar and granular material,” he said, noting the company has shifted its focus from building a demonstration project to building a commercial project.

It’s currently looking for partners among wind turbine manufacturers and wind farm developers, in which FWS provides the tower and construction component.

“Our engineers believe we can go straight to production,” said Depres.

“We would ideally prefer to erect a 110-metre tower before building a 140-metre tower, but under the right circumstances, we’re ready to go.”

Recent Comments

comments for this post are closed