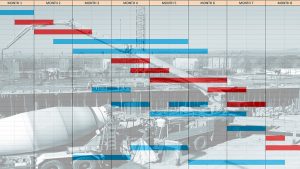

Over the next two years, two parallel bridges spanning the Athabasca River in Fort McMurray will be rebuilt to beef up vehicle capacity in and out of the Alberta oilsands’ major centre.

Over the next two years, two parallel bridges spanning the Athabasca River in Fort McMurray will be rebuilt to beef up vehicle capacity in and out of the Alberta oilsands' major centre.

In October, the two-lane, 473-metre-long Ralph Steinhauer Bridge was closed for a $51.7 million rebuild that will widen the two-lane bridge into three Edmonton-bound lanes by fall 2013.

Also in October, the Grant MacEwan Bridge, again 473 metres long, was shut down for a $23.3 million rebuild that will see the two-lane truss bridge transformed into a two-lane girder bridge.

The MacEwan will also be lowered to reach an underpass. The project should be finished by summer 2014.

Traffic that would have crossed the two out-of-commission bridges has been diverted to the new $127 million, five-lane Athabasca River Bridge, Alberta’s largest bridge deck, which opened in October.

Once the Steinhauer and MacEwan bridges are complete, the Athabasca bridge will accommodate only northbound traffic, headed to the oilsands.

At the MacEwan bridge site, demolition started in mid-February and is forecast to finish in April.

The lead contractor is Ontario-based Innovative Civil Constructors.

In the past, berms were built so that heavy equipment could work from the bottom to demolish existing structures, drive piles and construct new piers.

But berms can have environmental impacts.

For these two projects, work will be done without berms, said John Kerolus, a construction engineer with Alberta’s Ministry of Transportation.

Another benefit of not using berms is that Transport Canada clearance won’t be required.

When berms are used, they restrict travel on the waterway, a matter that Transport Canada monitors.

Instead of berms, an ice bridge is being used for the MacEwan demolition.

Water was pumped onto the frozen Athabasca River.

Once frozen to a certain thickness, the surface is ready to serve as the work site.

However, there is one condition, when built-up by flooding, the extra ice has to be removed before break-up.

As for when work can start on a frozen river or an ice bridge, there is no minimum thickness requirement, Kerolus said.

It’s up to the contractors to determine how thick the ice needs to be before heavy equipment can safely begin to operate and that, of course, depends on the temperature.

Engineers are hired to do loading analyses based on the equipment, while contractors assume liability and monitor the ice.

For the MacEwan work, cranes were placed on the frozen river.

The tops of the trusses were then cut.

The weight of the centre span was held by the cranes.

The trusses were slowly dropped down to the ice bridge, Kerolus explained.

The sub-contractor handling the demolition work is Edmonton-based McColman and Sons Demolition.

The trusses and other items will be loaded onto transport trucks and hauled to Edmonton, where the material will be crushed and disposed.

Dangers involved in the demolition include working on the ice bridge, the proximity of heavy equipment and the ever-present steel cables, Kerolus said.

After the old bridge is removed, work will begin on the piers.

The MacEwan bridge will have a total elevation decrease of 4.16 metres from the centre crown to entry into the tunnel.

Some of the piers will be removed, but the bridge will retain it’s 473-metre length.

Traffic will arrive in downtown Fort McMurray via the new Franklin Avenue underpass.

At the Steinhauer Bridge, the lead contractor is Flatiron Construction Corp., headquartered near Denver, Colorado.

The rebuild will be done in two stages.

In Stage One, downstream girders will be removed first and abutments will then be reshaped.

Pier caps will then be widened from 13.72 metres to 17.35 metres to accommodate the new third lane.

New girder lines will also be built and the deck formed.

As for Stage Two, the team will use the downstream side to demolish the upstream end, Kerolus said.

The bridge’s metal girders will be cut into manageable sections and removed, according to Christie DeLuca, Flatiron’s communication manager.

The concrete deck is being saw cut into panels and pulled off.

Portions will be chipped onto the ice and removed.

When the piers are demolished, the concrete falls onto the ice where it is collected.

As long as the ice is strong enough, pieces of the demolished bridge can be dropped on the ice.

When the Athabasca has thawed, nothing can be dropped in the river.

“It slows us down a little because we have to put additional containment in place when it is flowing,” DeLuca said.

Because the Athabasca is a fish-bearing river, there are restrictions regarding in-stream work.

Before work could begin, approval from the federal Department of Fisheries and Oceans was required.

Provincially, Alberta Environment has a Code of Practice which contractors must adhere to.

And even before pre-construction meetings, the contractors must prepare an ECO (Environmental Construction Operations) Plan for Alberta Transport.

All site specific aspects such as waste management, hazardous material handling, scheduling and potential environmental impacts must be addressed.

The document must also be updated as the project progresses.

To ensure each company’s ECO Plan is being honoured, an on-site consultant, hired by Alberta Transport, monitors the project.

As work continues, Kerolus expects peak construction at both projects to reach between 50 to 75 workers.

Both bridges will have FAST (Fixed Automated Anti-Icing Spray Technology) which includes the presence of nozzles on the bridge deck that will spray a solution to prevent the bridge deck from icing-up.

Also, the epoxy rebar, which is typically used on bridges will be substituted with stainless steel rebar to mitigate the effects of corrosion.

Recent Comments

comments for this post are closed