A lack of proper engineering drawings and series of unsafe work practices at a high-rise construction site in downtown Vancouver led to the death of a carpenter, who was crushed by a wall form in December 2010, according to a WorkSafeBC report.

A lack of proper engineering drawings and series of unsafe work practices at a high-rise construction site in downtown Vancouver led to the death of a carpenter, who was crushed by a wall form in December 2010, according to a WorkSafeBC report.

“This incident — like all workplace fatalities — was preventable,” said Jeff Dolan, WorkSafeBC’s director of investigations.

“The investigation results show a number of factors contributed to this tragedy.”

Dan Martens, 28, was killed at around 8 a.m. on Dec. 2, 2010 while working for HP Construction Ltd. on the 30th floor of Three Harbour Green high-rise, a luxury residential development in Coal Harbour.

A report released by WorkSafeBC on May 30 identifies the cause and underlying factors that contributed to Martens’ death in a workplace fatality.

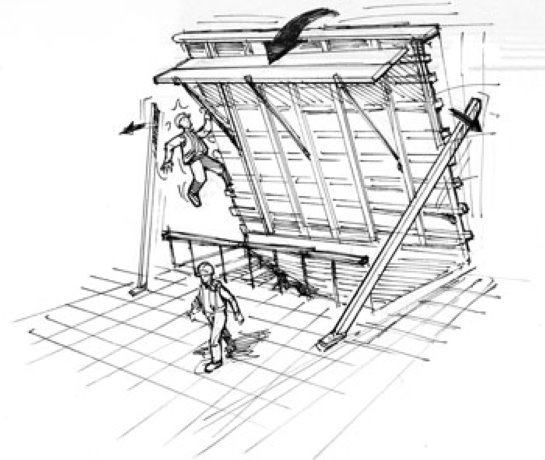

The report concludes that Martens was crushed and killed by a wall form weighing about 1,260 kilograms, which suddenly became unstable and fell over on top of him. The cause was a lack of design drawings and a series of unsafe work practices.

To begin, Ted Newell Associates Inc. drafted engineering drawings for the erection on the ground floor or foundation level, which means the wall form is supported on a level surface. The engineer conducted a pre-pour inspection of the wall form at the foundation.

However, once this work was complete, HP Construction made changes to the erection method, so the form work could be used to construct walls on higher levels.

On subsequent floors, where a level floor wasn’t available, for example over a stairwell, the wall form was erected using load blocks.

These are blocks of wood used as ledges to support the wall form.

The wall form was not centred, but was placed unevenly on the blocks, adding to its instability.

HP Construction didn’t ask the engineer to conduct additional inspections after the erection method changed.

In addition, drawings were not provided by Ted Newell Associates for the erection of the wall form using load blocks.

Next, a worker with Lower Mainland Steel was climbing up the side of the wall form to access a work platform, which was prohibited by both HP Construction and Lower Mainland Steel.

The added weight of the worker climbing the wall form contributed to the wall falling over.

When the wall form suddenly fell, the steel worker jumped clear and managed to avoid injury.

Finally, the form was held in place with form aligner braces, which were constructed of pieces of wood with metal turnbuckles.

The top of the brace was inadequately fastened with two nails to the outer edge of a 4 x 6 wood waler on the wall form.

The same wall form had been used many times, so the ends of the walers were damaged and cracked from repeated nailing.

Inadequate bracing connections also contributed to the wall form’s instability.

In conclusion, the wall form was erected and supported on load blocks with an unequal cantilever at the base at each end.

There were no structural elements to prevent lateral movement.

When the worker climbed up the walers on the wall form, one of the end load blocks kicked out and the braces were unable to resist the resulting forces to keep the form from falling.

As a result of this investigation, orders have been issued on HP Construction and Ted Newell Associates.

They were required to provide drawings with complete information for all formwork, including the design standards, design loads and connections for all formwork components.

The erection drawings must include details of all necessary supports, such as braces and ties, which are required to maintain stability during all stages of erection. A professional engineer must approve any design changes to the wall form.

WorkSafeBC is currently considering penalties against HP Construction and Ted Newell Associates.

Ledcor was the prime contractor on the project.

Recent Comments

comments for this post are closed