The design and construction of midrise engineered wood buildings can be “compromised” without a careful selection of materials, connections and assemblies.

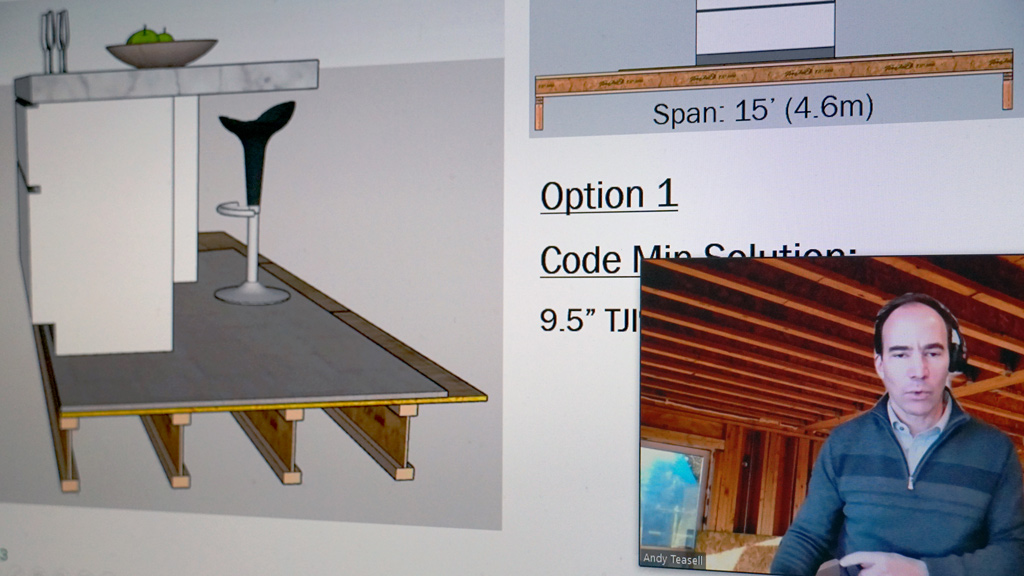

“Whether it is the right product for nailing or shrinkage or excessive deflection…you don’t want performance surprises,” Andy Teasell, a senior engineer at Weyerhaeuser’s Trus Joist product line, told an audience recently at a webinar hosted by the Canadian Wood Council.

Teasell said there are many complex facets to midrise engineered wood buildings that are not common in regulatory controls such as Part 9 of B.C.’s Building Code.

“As successful as they (mass timber buildings) are, the stakes are high and they require more expertise” than conventional construction, he said.

Make it a priority to work with qualified suppliers and select products based on their performance, he advised his audience.

“It reduces the risk to your schedule, performance and those dreaded change orders later on.”

He said while laminated veneer lumber (LVL) is widely used for midrise buildings, designers and builders should take a close look at the advantages of laminated strand lumber (LSL) and parallel strand lumber (PSL).

LSL, such as Weyhaeuser’s Microllam, “does a great job in beams” and another LSL product called Timberstrand is “generally priced less” than LVL, Teasell told the webinar.

PSL (Parallam, for example) is suited to beams and columns because it can be produced in thick sections, he said, adding its higher upfront cost can be offset in some midrise applications through less need of labour and materials.

Like Parallam, Timberstrand (an LSL) can do away with bolt and nail patterns on side-loaded applications because it is available in 3.5-inch thicknesses, Teasell explained.

The advantages don’t stop there. Eighty per cent of LVL-2.0E beam designs can be substituted with the same sized -1.55E Timberstrand and save the builder money.

As an example, almost all of the 8,500 lineal feet of beams originally specified in LVL for an Ontario building were changed over to Timberstrand, “resulting in thousands of dollars of savings,” he said.

While Timberstrand shows “good shear numbers,” it also offers vertical stability, with minimal shrinkage.

Teasell advised builders to be specific about the beam types for midrise projects. Sometimes a manufacturer’s choices can “present challenges.”

If connections and beams are not selected than a model has to be built to track and determine loads. “When time is really tight they might have to make some assumptions…and it might invite some risk.”

Teasell suggested that specialty engineers usually are not required for mass timber midrises because many engineers will specify the brand, size and grade of materials.

When evaluating alternative materials, however, steer away from “dramatically cheaper material because it could indicate something got missed or switched out,” Teasell said, noting that Weyerhaueser’ Trus Joist and its competitors are generally close on price.

Along with materials, assemblies and connections and specifications procedures such as shop drawing reviews are important to getting things right.

Teasell stressed the importance of carefully choosing partners on a project, including the trades.

“We know that it is not a good idea to put a hole in a joist right at supports, but not every trade knows that,” he added.

He said Weyerhaeuser has prepared documents for tradespeople to help them understand where and when they can install utility holes such as for plumbing.

Work with experienced suppliers, Teasell added, pointing out that good communication between the supplier and engineer helps avoid project trip-ups such as load transfer issues that might result in materials getting crushed.

He said his company provides a checklist for builders on the training and experience a midrise supplier requires. Beyond that, make sure to ask suppliers for examples of previous projects to see what has worked and why.

Recent Comments

comments for this post are closed