Bigger isn’t always better.

A liquified natural gas project that is roughly one per cent the size of other large-scale projects under construction or proposed in B.C. is aiming to prove just that.

Chris Hilliard, president of Port Edward LNG, explained at around $350 million, the project is by no means small, but is dwarfed by other LNG projects that cost tens of billions of dollars.

“That is the primary difference: scale. We still are taking natural gas, cooling it to -162 C, it occupies 1/620th the volume of the gas, and that is what enables it to be transported economically,” said Hilliard. “There is nothing new about what we are proposing.”

One difference would be loading the product into individual containers rather than massive containing vessels. Hilliard explains this would allow their target customers in Asia to pick up the product at regular container docks.

“It will be delivered much closer to them and in a cost competitive manner,” said Hilliard. “That combo means our timelines for construction are shorter. We aren’t building a pipeline or a new dock. Those are significant hurdles for capital and time. On the downstream end the customer has more direct access. Those are the key competitive advantages.”

Hilliard has been in the LNG sector for more than a decade and he brought his experience in investment with him. While running a clean technology battery company he was approached by several engineers about a different approach to LNG who predicted B.C. would be a hotbed for the industry in the coming years.

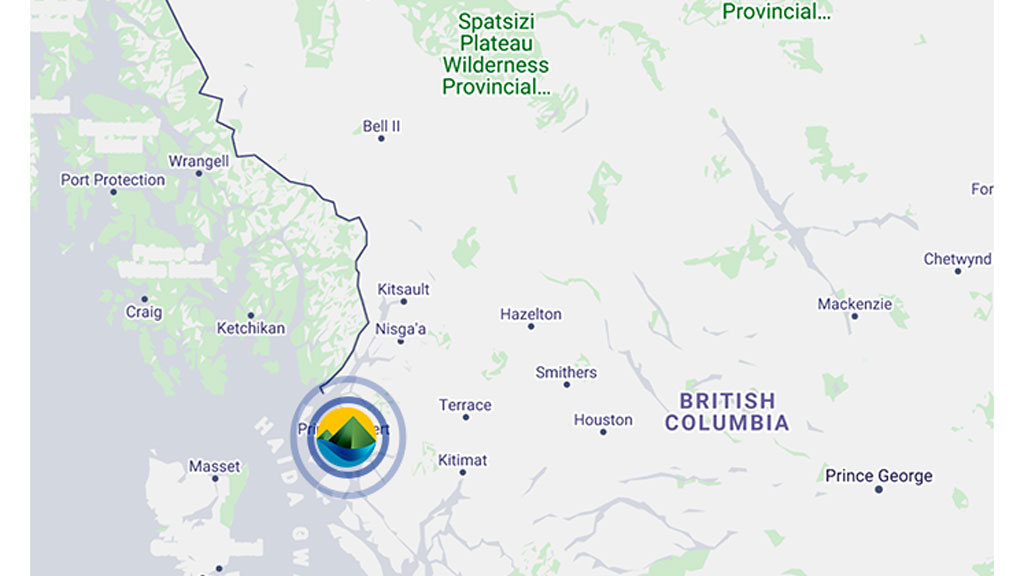

The project would be built on a 37-acre site approximately five kilometres east of Port Edward, adjacent to existing industrial facilities including BC Hydro operations and a natural gas pipeline. It would have the capacity to generate 300,000 tonnes of LNG per year and connect to the existing Pacific Northern Gas natural gas pipeline. It would use off-the-shelf technology rather than creating a bespoke facility from scratch and would not require a new dock or jetty.

The project received its initial permit last year and the final permit amendments were given six weeks ago. Hilliard says the project team aims to get shovels in the ground this summer.

The construction timeline is two years, with the first year spent on civil works like site preparation and the second year spent on construction and commissioning. This would lead to first liquids in the summer of 2024.

“We have a short schedule to get to first liquids, so the opportunity for us as a business is quite strong,” he said.

The project would be built and operated on the traditional territories of the Tsimshian communities. Hilliard explained the project team has worked hard to build strong relationships with the area’s Indigenous people and is working with them on ways to be included in the project.

“Our approach was to reach out to them before we reached out to regulators and government,” he said. “Our stance was that if there’s an opportunity here, you will be included and let’s discuss how. And we have taken a very aggressive stance in terms of communication with First Nations. A well-informed party is much more likely to become a direct stakeholder. That’s not finalized but we are open. This is their backyard and let’s do everything we can to walk together.”

Some of the major project hurdles for construction include sourcing equipment and labour. Hilliard said the project will use local labour whenever possible but will have to utilize Americans from the Gulf Coast who are experts in the specific LNG technology during the construction phase.

“It is not something that is made locally so we will have to blend that expertise with local expertise,” he said. “The Gulf Coast has experts in fabrication and construction of this, so the best of all outcomes is to partner effectively with folks from the U.S. as folks here build out their skill sets. That will enable future efforts.”

Follow the author on Twitter @RussellReports.

Recent Comments

comments for this post are closed