A University of B.C. researcher looking at innovative steel construction methods has devised a truss system that can be used to construct modular flooring and has the potential to reduce construction costs and time by 50 per cent.

It eliminates the wait time for concrete slab curing and also has the potential for repair of damaged flooring sections in the aftermath of an earthquake.

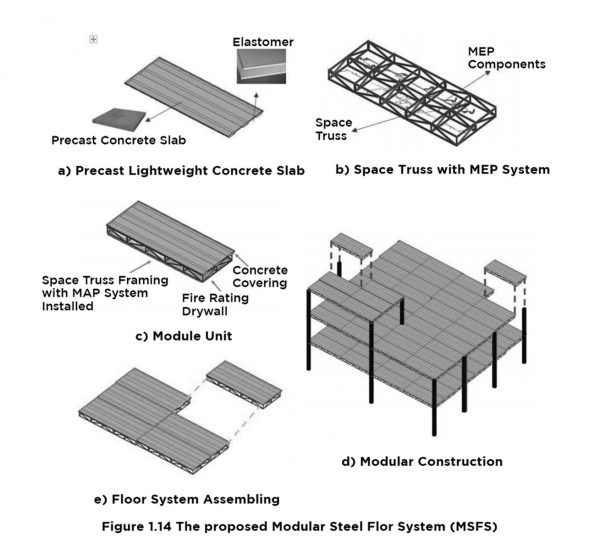

While other flooring systems exist, the challenge faced by the UBC team on the project was devising an economical and innovative modular system with seismic strengths. The design features a modular steel truss system (MSTS), which consists of a modular steel floor system (MSFS) and a modular buckling restrain braced truss moment frame (MBRBTMF).

The system is outlined in the thesis, Development of an Innovative Modular Steel Truss System, written by Sirou (Kelly) Zhuo, with a chapter on seismic stability contributed by Tony Yang, a structural engineering professor at UBC’s Department of Civil Engineering.

“This specially designed floor system (MSFS) consists of space trusses and precast concrete slab toppings and to fully utilize the spaces within the floors, the mechanical, electrical and plumbing systems are pre-installed within,” Zhuo said in her thesis. “The connectors between the modular units would be applied for quick and easy installation and assembling. Lastly, a fire rating drywall will be added as the final layer. This will be the finishing stratum of the ceiling for the proceeding floor system.”

The research carried out by Zhuo is part of the university’s civil engineering research group headed by Yang.

“This is one of the new inventions from my research group,” said Yang, who in 2014 received the H.A. Krentz Research Award from the Canadian Institute of Steel Construction (CISC), which is targeted to develop innovative high performance structural systems.

Zhuo also credits the research support of the CISC.

The group’s focus is on finding not only new structural systems but ones that would lead to efficient fabrication and higher performance ratings, said Yang in an email. Zhuo, a master’s student, has returned to her home in China.

The difficulty facing Zhou was designing a modular system that would be rigorous and flexible enough to deal with seismic events.

“The seismic performance of modular buildings under severe earthquake shaking may differ significantly from regular structures,” Zhou wrote in her thesis.

The MSTS consists of both a gravity and seismic force resisting system.

“The seismic behaviours of MSTS and conventional building structures using MSFS were studied and the results show that the proposed modular steel system, MSTS, is highly efficient and can be used effectively for modular applications,” Zhuo said.

The truss system relies on a new bracing concept.

Yang said Zhou had done extensive studies to optimize the design of the modular steel flooring system. She had combined it with a MBRBTMF, which was inspired by a buckling resistant knee-brace system.

“MBRBTMF is a novel structural system which has not been used in the industry yet,” Yang said.

It consists of steel trusses and buckling restrained braces (BRB).

The BRB, utilized as a structural fuse in MBRBTMF, is a highly efficient energy dissipation device, which is capable of absorbing significant energy under seismic loads.

“The structural fuses can be easily and efficiently constructed using bolted or pinned connections and can be more easily replaced after severe earthquake shaking, which makes the structures more resilient towards earthquakes. The performance-based plastic design (PBPD), presented by (Goel, Leelataviwat, 1998) is applied to design this novel structural system, since no prior design guideline was established,” stated the thesis.

Zhou said in her study the size of modular systems would be limited by transport capabilities in areas. The use of the modular flooring units would also reduce the need to find and use skilled labour in more remote or rural areas.

She said in her introduction there was the need to make the steel building construction sector more efficient through modularization as the steel market had been losing market share to both concrete and other forms of modular building construction.

“The Council on Tall Building and Urban Habitat (CTBUH)’s database (Council on Tall Buildings and Urban Habitat, 2017) reveals that, over the last five decades, steel market shares have declined significantly, while those for concrete and composite material have simultaneously increased,” Zhuo writes.

She provided a chart which showed the material of the 100 tallest buildings per decade showed a significant shift with 1970 steel buildings having a 90 per cent share while in 2017, that share dropped to 10 per cent.

Zhou pointed to reasons for pursing modular such as quality control in the manufacturing facility, less reliance on weather at the site, faster construction time and less waste.

The research still needs to be brought into the field as it has not been used in a building in Canada, said Yang.

“I am a member of the committee for writing the National Building Code of Canada. We will continue to work to implement such a system in our building code,” Yang said.

Recent Comments