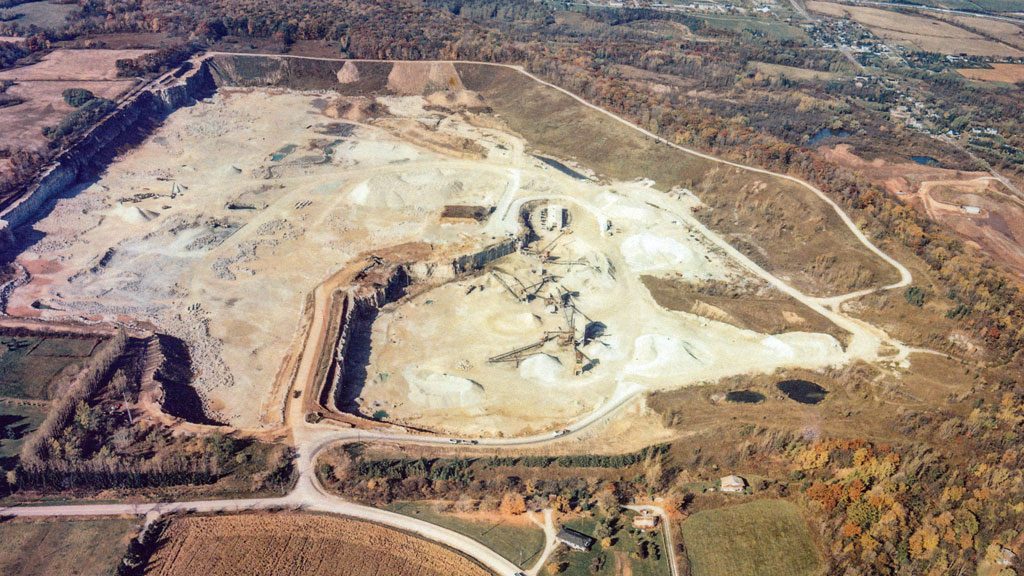

In what might be considered a symbolic comparison to the endless lines of gravel trucks which once poured through its gates, Kelso Quarry Park is on a journey of sorts. In this case the destination is the complete transformation of what was once the Milton Limestone Quarry.

For the past two decades a series of restoration projects have been undertaken and a major event commemorating what has been achieved occurred last July when the park was awarded the Ontario Stone, Sand & Gravel Association’s (OSSGA) Bronze Plaque.

Affixed to a large, decorative stone marker, the plaque acknowledges the quarry rehabilitation efforts undertaken by Conservation Halton, which is the regional watershed conservation authority, in partnership with the Town of Milton.

Only 21 rehabilitated former pits and quarries have received this award since it was established in 1975 by the association, a non-profit industry association representing over 280 stone, sand, gravel, and crushed stone producers and suppliers of valuable industry products and services.

Located on the Niagara Escarpment just north of Milton and adjacent the popular Kelso-Glen Eden Conservation Area, the 71-hectare former quarry was established in 1958 to provide aggregate for the construction of Highway 401 and, at one time, was one of Canada’ largest producers of aggregate.

In 1995, as the quarry was nearing its extraction license limit, Conservation Halton and the quarry owner began “collaborative rehabilitation plans” for the restoration of the property and its eventual transfer to the authority. The quarry was closed in 2001 when the last aggregate was extracted, says authority watershed restoration planner Nigel Finney.

In 2006 owner Barrick Gold Corporation completed the required rehabilitation conditions and the property transfer was completed.

Since then authority has conducted several projects intended to improve the park’s ecosystem including creating new wetlands, building of trails, marsh plantings, and extensive tree planting which actually began before the property transfer.

Many of those projects “would not have been possible without the dedicated work of community residents.”

The construction industry also played a major role in one of the most significant and extensive components of the multi-phase, multi-year undertaking. A pivotal feature of the quarry is an approximately 32-hectare manmade lake and in late 2015 Conservation Halton embarked on an ambitious undertaking to enhance fish habitat through the creation of fish spawning shoals.

Comprised of gabion stone, clay till, and round river stone, the shoals were built in three areas on the north and west side of the lake.

An in-house restoration ecologist created the shoal design which was based on existing outcropping of shallow rocks as well as planned future uses of the lake, he says.

“Each shoal was designed to provide spawning opportunities at different depths,” says Finney, pointing that several factors have to be taken into account when designing and building fish habitat shoals, including the clarity of the water.

Conducted over a two-month period in December 2015 and January 2016, the shoal project partners included Dufferin Construction, which donated a portion of the approximately 45 truckloads of required aggregate. It was transported to the quarry from a pit in Waterloo Region. As the aggregate was being delivered, it was graded into place by Guelph-based Tri-City Equipment.

“Installation of the shoals occurred when there was ice on the lake and a long-range excavator was needed to break through the ice before placing the rock,” says Finney, explaining this work had to be conducted in the winter to comply with regulations governing in-water construction.

Another industry player was Eco-Tech Construction which placed woody debris in the lake and an adjacent wetland. They will serve as perches for waterfowl and basking habitat for turtles.

Later that same winter fish habitat structures in the form of three-metre high, 1.5-metre-wide (eight-foot-high, five-foot wide) free-standing wood cribs were installed near the shoals by Conservation Halton staff with the help of Niagara College restoration students and community volunteers. Built with rot-resistant cedar logs, the cribs were filled with conifer bush and cinderblocks weighing between 362 to 453 kilograms (800-1,000 pounds), says Finney.

Since then restoration initiatives at the quarry have been placed “on pause” because of budget restraints. However, authority is updating a master plan and undertaking a public consultation process with the twin goal of protecting the park’s natural and cultural features and enhancing recreational and educational amenities, says Finney.

What has been realized to date “represents the best of the best among thousands of rehabilitated former aggregate extraction sites in the province,” OSSGA executive director Norm Cheesman told participants at the park dedication.

“The diverse ecosystem that has been created in the heart of the Niagara Escarpment is why this site is so exceptional.”

Responding to a question on why the association didn’t wait until the restoration was fully completed before presenting the award, Cheesman pointed out the process for awarding the bronze plaque started in 2016.

“It’s an extensive, multi-year process to review applications. Judging is completed by OSSGA’s rehabilitation committee which is comprised of aggregate producers and consultants with expertise in the area of rehabilitation of pits and quarries.

If an application meets all the criteria, the committee makes a recommendation to OSSGA’s board of directors that an award be granted. This can take time.”

As well, the onsite ceremony was intended as a public event to showcase the rehabilitation, says Cheesman.

Recent Comments