The largest single capital investment in Hamilton’s history is officially titled: The Woodward Avenue Wastewater Treatment Plant Upgrades.

But that heading doesn’t really convey the full scope of an approximately $340-million upgrade of the city’s main wastewater treatment plant — the purpose of which is to improve the water quality of Hamilton Harbour.

Preceded by planning, public consultations, and design, the upgrade project is intended to manage wet weather flows, provide better treatment capacity and meet a number of objectives defined by the Hamilton Harbour Remedial Action Plan (HHRAP) — a long term undertaking to restore the harbour.

A major objective of the upgrades is to meet the HHRAP’s targets for the reducing the amount of ammonia flowing into the harbour, “as ammonia in high concentrations is toxic to flora and fauna in aquatic ecosystems,” says Andrew Grice, director of Hamilton Water.

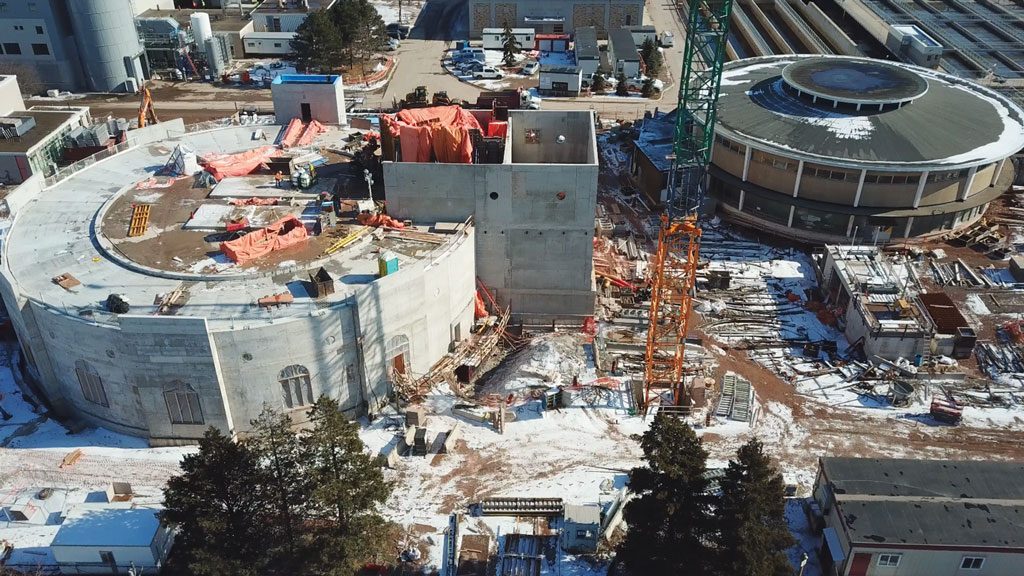

And attaining that objective is the reason new tanks are being added to Woodward’s secondary treatment process — which is comprised of two plants. Work started in 2019 and won’t be completed until 2021.

The addition will enable those plants to convert ammonia to less harmful nitrate on a year-round basis. Capacity limitations have hindered that ability with the result HHRAP ammonia reduction targets haven’t been met. However, when the new tanks are in service that will all change, says Grice.

“It is estimated that approximately 6,100 tonnes of ammonia will be removed from the aquatic ecosystem over the next 10 years of post-construction.”

North America Construction (1993) Ltd. is the general contractor building the tanks and it’s also carrying out the parallel construction of a new disk filtration tertiary treatment facility which will also reduce approximately 500 tonnes of phosphorus and 15,000 tonnes of solids during that same 10-year period, says Grice.

At an estimated cost $165-million, the work being conducted by North America Construction is the largest and most expensive of three separate contracts which make up overall Woodward upgrades project. Still, the construction schedule is actually the shortest of those three because of the contractor’s parallel work and the fact that the disk filtration tertiary treatment facility is being built on a greenfield site with limited below-ground obstructions is the reason, he says.

The origins of the Woodward upgrades project dates to 2008 when the City of Hamilton completed an environmental assessment to determine a plan for the upgrades, as well as preparing for future growth.

“But then the 2008/2009 recession hit and there was a decrease in water consumption, so we decided to focus entirely on improving water quality.”

In 2016 the first step of plan was put into place with the launch of a long-term monitoring program to measure the impact on the Red Hill Creek. The secondary treatment effluent discharge flows into that creek, but the discharge channel will have to be moved one kilometre to the north when the upgrades program is completed. The monitoring will continue until at least 2031, says Grice.

To provide the necessary power supply to all of Woodward’s existing and planned new processes, a major electrical overhaul began in 2017 and will continue until 2021. The existing electrical substations have been in service for over 50 years and are nearing the end of their normal service life. They don’t have the sufficient capacity to accommodate the power requirements of the process upgrades.

Alberici Constructors Ltd. is erecting a new power centre consisting of four standby 3,000-KW diesel generators, plus installing a dual 13.8 kV back-up distribution loop right around the entire Woodward site which also includes a water treatment plant.

During the same period, 2017 to 2021, a new 1,700 wastewater MLD wastewater pumping station is being built just upstream of the secondary treatment plants by Maple Reinders.

The Woodward upgrades project is being led by Jacobs, which is the prime consultant, and AECOM, with support from Wood. In addition, there are a number of specialty sub-consultants used for subsurface utility investigations, geotechnical, environmental, and designated substance surveys.

Asked how the planning and co-ordination of a such a lengthy, complicated, and expensive project was and is being carried out, Grice said it involved the creation of a series of separate sub-project teams consisting of both city and consulting staff. The design was undertaken over the course of several years, with key “deliverable milestones” at different stages.

In summarizing the history of the Woodward upgrades, he points out there has been a complete reversal in Hamilton’s economic status compared to 2008 and 2009.

“It’s now booming,” noted Grice.

With that growth, may come an increase in wastewater flows and that is being monitored to determine if a capacity expansion will be required. But that’s not anticipated until after 2026, he says.

Although not part of the upgrade’s improvements, other construction is also occurring at Woodward including the erection of a new biosolids management facility which is currently on track to open May 1, says Grice.

“This is quite a busy place and, at any one time, there can be 300 workers on site.”

Recent Comments

comments for this post are closed