Civil engineering students at the University of Victoria in B.C. are taking a crack at solving concrete’s sustainability problem.

Research they conducted found that embedding steel fibres in concrete reduced the amount of cracking and improved flexural strength of the material. Less cement was also needed for the mix, so it was more environmentally friendly.

“If you do it right, it can actually eliminate cracking completely,” says Prof. Rishi Gupta, director of an undergraduate program in the department of civil engineering at the university. “In this particular case, the steel fibres actually showed that the flexural strength or the bending strength of the samples can be improved.

“If you have a little piece of regular concrete and you have a few people standing on it, when it snaps it’s going to snap into two pieces and is very brittle. But if you had steel fibres or any sort of reinforcement it’s still going to have that first crack but it’s not going to break into two pieces. It’s still going to hold together and that’s great for things like seismic applications and impact and those kinds of things.”

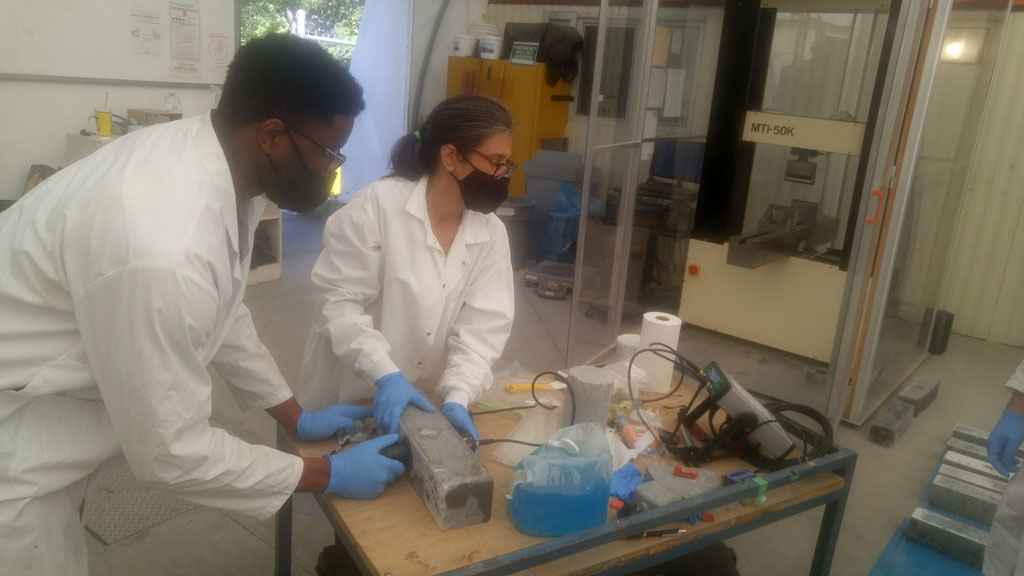

The research was done over the summer months by a class of four graduate and undergrad civil engineering students in his Sustainability and Advanced Concrete Technology course. The students were Blaise Eze, Jared Barrow, Jarod Rossander and Perla Rodulfo. The professor supervised their project.

Sustainability is the underlying theme of projects done in the course. When an idea or project is proposed to students, they are asked to push the boundaries and find a new way of approaching the problem.

“This is what sort of led to the project,” Gupta, who works in the Facility for Innovative Materials and Infrastructure Monitoring, explains. “The students came up with the whole idea of using steel fibre reinforcement in concrete.”

The project, aptly named the Steel Fibre Reinforced Concrete (SFRC) project, entailed adding and mixing steel fibres into the concrete – the old-fashioned way with a wheelbarrow and shovels. It was painstaking and dirty work.

“We did everything basically from scratch,” says Gupta. “So, they laid out the cement and the aggregate and sand and then they mixed the fibres. It was like a mini construction site.”

Because concrete is employed in structural engineering around the globe, there is interest in materials that would give it more tensile strength and make it less vulnerable to cracking.

Adding fibres to concrete helps to make the material less brittle and gives it increased toughness and ductility, improved fatigue and impact resistance, and reduced cracking, as well as better post-cracking behaviour.

Fly ash and synthetic materials are often used to give the hardened concrete more strength and durability. When the materials are added to the concrete, the amount of Portland cement may be reduced.

The advantage of using steel fibres, however, is that they expand and contract at the same rate as concrete so there is less chance of cracking.

“The other advantage is that steel is relatively stiff when compared to some of the other choices that you have such as synthetic fibres,” explains Rupta. “So, when you’re looking for something that is structurally strong – and with perhaps a hint that the amount of structural rebar could be reduced a little bit, if not eliminated completely someday – then the first thing that comes to mind is steel fibres.”

Tests were carried out on the cured concrete. After the performance of several non-destructive and destructive tests, the team found the design and performance of the concrete with steel fibres mitigated the propagation of cracks. All concrete specimens where steel fibres were added also had increased load-carrying capacity when cracks appeared.

The specimens containing SFRC had a higher tensile strength and flexural toughness, which was 1.5 times higher compared to the results of the test performed on the concrete with no steel fibre reinforcement.

The research concluded concrete with steel fibres will result in more durability and therefore a longer service life of a concrete structure.

The team suggested the use of steel fibres in concrete can reduce the total energy consumption of a project and will contribute to sustainable building practices, and that the SFRC can be applied in a wide range of applications such as pavements, sidewalks, rock slope stabilization, construction of precast products and concrete pipes.

Gupta says steel-fibre reinforced concrete can be used for projects big and small.

“The answer may be that the general family of fibre reinforcement could be used anywhere. Steel fibres – when you’re talking about structural concrete – would make a lot of sense.”

Another advantage is that because the steel fibres would be pre-mixed into the concrete at the plant, there may not be a need for as much rebar or steel mesh to be put down for concrete pours, thereby reducing labour requirements.

“You sort of remove that requirement for a person to put the steel mesh in place. The concrete truck shows up with concrete fibres pre-mixed from the plant and off you go.”

The only drawback to steel fibres, he notes, might be in sidewalks.

“You typically don’t want to have steel fibres in your pavements because you could have steel fibres sticking out and result in a bunch of flat tires. If the fibres stick out, you wouldn’t want that.”

Recent Comments

comments for this post are closed