As crews with a London area survey firm head to work on a massive wind farm development underway in Ontario’s Niagara region, you can rest assured there is one tool they won’t be leaving behind: GPS.

Over the past decade, global positioning systems have become an increasingly common resource on the construction site, especially those situated in remote or open areas, says Rob Hern, owner and president of Trueline Services Inc.

Indeed, GPS has become key to the delivery of the Komoka, Ont. firm’s services such as construction surveys, topographical mapping and pre-engineering surveying.

"We’ve been using them (GPS devices) since 2004," says Hern.

"We also do construction layout for GPS. We create a data file off the AutoCAD drawings that are provided by the engineer — the point plan — and then we can use it for laying roads, sewers, watermains, surfaces, street lighting, any surface detail."

The technology can also be used to calculate the earth volume quantities used in site excavation and grading.

Hern explains they will go in and record the site with a GPS unit and then return after the area is excavated to obtain more readings. The readings from the two surfaces are used to calculate the volume of topsoil that has been excavated.

"Once they (excavators) do their cut/fill, we can also go back in and shoot again with GPS to create a final grade model, and then we can compare from the stripped surface to that final grade surface to come up with a calculated volume of how much material they’ve moved on or off site," he says.

The technology has some significant advantages.

Trueline is currently involved in Enercon GmbH’s $950-million Niagara Region Wind Farm that broke ground last year. On such projects, using GPS for surveying knocks off up to 60 per cent of the time it would take to do the same work using traditional methods, Hern says. When you’re talking about surveying the locations for 77 wind turbines over three municipalities, that’s a lot of labour savings.

Creating precision during the excavation process as well as reducing construction labour needs are other benefits. Hern explains GPS data is used to build a three-dimensional model of the finished grade from engineers’ drawings.

"Then we go to the site and set up their site control and their base station, and then we can also assist in loading that data on to their equipment onsite."

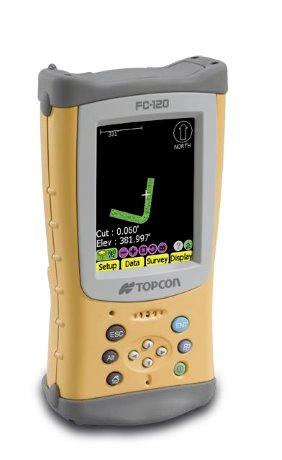

Monitors in equipment in turn provide an on-the-go three-dimensional view of the ground to guide operators on how much to cut or fill to achieve target elevations.

"It’s more handy," he says. Operators "don’t have to have a grade man on site chasing them around, re-staking and setting grades. Now it’s more automated."

In a presentation to the Canadian Farm Builders Association in January, Dan Hendriks, senior vice-president Eastern district, GeoShack North America Inc., noted greater measuring accuracy could generate more exact estimates of the volume of material needed, such as fill. For the contractor, all that precision generates cost savings and can mean presenting more competitive bids. Moreover, Hendriks says, adding GPS technology to help guide construction equipment activity eases the ongoing challenge of finding skilled operators by enabling less skilled workers to run the machine while it does the work for them.

But using GPS comes with caveats, one being that it is best suited to remote and open areas, Hern says. The devices are no good in areas that are heavily treed or have tall buildings, he explains.

"The technology is getting better but it’s still a signal that comes from a satellite, so there has to be an open path from the satellite to the receiver for it to work properly."

In perfect conditions, GPS might deliver centimetre accuracy but more usual is accuracy of "one to two centimetres plus or minus vertical accuracy," he says.

So for items such as footings and foundations or bolts or road curb and gutters where grade is critical, his company employs other equipment. Hern also advises that the technology is only as good as the data that’s supplied.

"You have to make sure that you have good engineering drawings to work with to begin with," he explains.

Nevertheless, it still impresses him how much time the technology can save. Under the conventional survey method crews could take up to two days to establish the reference coordinates needed for work to begin.

"Now you can turn on a GPS and it gives you coordinates right where you are."

Recent Comments

comments for this post are closed