The procurement landscape in Ontario and beyond continues to change, with more questions arising than ever before.

“We’re considering awarding contracts even before we launch a project and we know that it’s viable. There are some challenges with that because what happens if the project does not have a successful launch? Are we starting construction? Are we not starting construction? And when can we start construction and how long can those prices be held for?” said Jennifer Burstein, vice-president of construction with Collecdev, during a recent panel discussion.

“The lump sum contract is still pretty familiar in the industry, but it needs a start date and it needs to have schedule certainty around it because of escalation.”

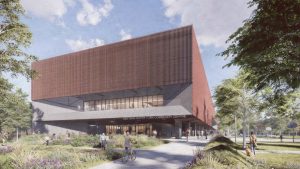

The discussion, Industry Forum: Procurement Risks and Solutions, was part of the Toronto Construction Association’s 28th annual Members’ Day, held at the association’s Richmond Hill, Ont. office May 3.

From a general contractor’s perspective, Paul Dipede, general counsel of Corebuild Construction, said there are a lot of lump sum tenders in the private sector but the construction management model is being used more and more.

“Because of the price escalation, the fluctuations, the volatility of all of the commodities, I think we see the ability to tier tendering is a lot more beneficial to our subcontractors because you are able to lock in your prices a little bit later on in the tendering process,” he said.

“Our company, we do a lot of public tendering as well and you’re actually seeing some of the typical lump sum owners…school boards or long-term care owners, are actually changing from your stip sum CCDC 2 model to a CCDC 5B because A) your drawings are not complete or B) there is a lot of volatility in pricing and sometimes it’s not viable to enter into a CCDC 2.”

Tim Theodosiou, vice-president of special projects with Modern Niagara Toronto, said when it comes to cost, the company has looked at different options from early purchasing to offsite storage of materials.

“We haven’t found any bulletproof solutions, but one thing we found is being very transparent with our clients and our owners to give them realistic expectations as early as we can,” he said. “If you start that early on and you start to build the schedule around the longer lead items…for us in mechanical equipment, if we know it’s going to be late on a project we’ll plan for that early so we’re not holding up the project.”

The team has also found creative approaches to expedite certain areas, he added.

“For us, the electrical room, mechanical room, that would typically get pushed off to the back end of the project,” Theodosiou explained. “Now the construction of those rooms will get pushed up to allow some of the big value items to get moved onto site. The ability to store the materials and equipment offsite has been expensive and the handling of all that has been expensive but in some cases we have been able to work with our builders, find areas on the jobsite, secured areas.

“We’re able to move some of the items into those spaces.”

If the contract price is locked in, there is not much you can do about price escalation from a legal standpoint, but from a collaborative standpoint your GC and your subtrades can co-ordinate to find solutions, Dipede said.

“There are methods you can employ on the project to re-co-ordinate the work,” he explained.

“That’s not only on the jobsite but your accounts receivable and your AP. You can procure long lead items…That’s what we have to focus on as contractors in the industry is finding out ways to work with the system that we’re all in.”

Burstein said there have been a lot of difficult negotiations over the last few years to find that balance.

“Legally speaking, trades…they’re experiencing cost increases on their end and so they’ll come back to you the CM, GC or developer directly and say, ‘Look, I thought I could buy it for X, now it’s going to cost me Y and my business just can’t support this,’” she said.

“It puts you in a position where you have to really assess is this going to result in insolvency if they can’t actually provide the material at this cost? Am I going to lose a trade on this project? Am I going to have to find someone new to do the work? And finding someone new at this point is going to cost me more than potentially negotiating an extra with this given trade.”

Theodosiou said increased communication of projects has also become a necessity over the past few years.

“I think that has helped us plan for a lot of the challenges that come with this and at least be a bit more compassionate to our trade partners and our suppliers of what they’re experiencing.”

Recent Comments