A U.S. engineer has conducted a study on which type of bridge is the best, steel or concrete, and his findings may be surprising to some.

“I talk to a lot of counties, a lot of consultants and a lot of state DOTs (departments of transportation). One of the most common questions they have is which are the best bridges for lifecycle costs,” Dr. Michael Barker, a civil and architectural engineer and a professor University of Wyoming, told the audience at the recent webinar entitled Accelerated Bridge Construction, presented by Acrow and hosted by the Ontario Good Roads Association (OGRA).

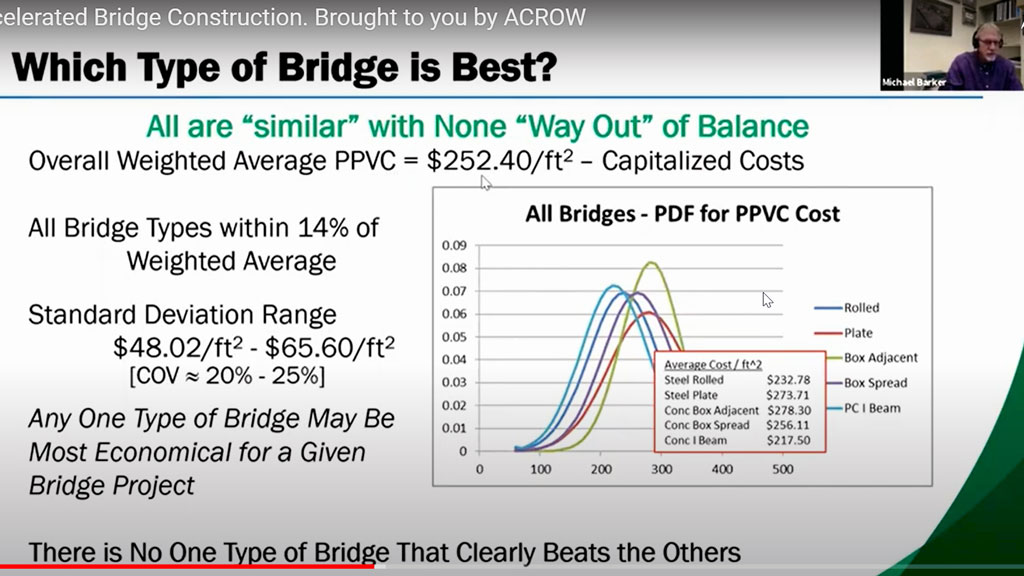

Barker carried out a large-scale analysis on bridge structures and summarized his findings during the webinar. The study compares precast I-beam, box adjacent, box spread bridges, steel rolled and welded plate girder bridges. The study found all are “similar” with none “way out” of balance, he said.

“Statistically any one type of bridge may be most economical for a given bridge project. There is no one type of bridge that clearly beats the others,” said Barker, who is also director of education for the Short Span Steel Bridge Alliance.

“There is a preconception out there that concrete is less expensive than steel.

“The results of this, and what we’ve known for a long time, is that typical concrete and steel bridges are competitive on initial costs, future costs, lifecycle costs and bridge life and that owners should consider both steel and concrete alternatives for individual bridge projects.”

In conducting the study, he looked at historical lifecycle costs, historical life service, performance and maintenance, and agency lifecycle costs of steel and concrete girder bridges. He needed a comprehensive inventory of bridges to be able to do comparisons including initial costs, date built, maintenance costs, including the date performed and how long the bridge lasts or the end of service date.

“The bridges in the Pennsylvania inventory are still in service so I had to come up with an end-of-life model,” Barker explained. “If I assumed the bridge was a superstructure condition rating — in the U.S. that’s what we use — of a nine when it was first built, which means it was a perfect bridge, then given that I looked at these bridges in 2014 I can calculate a deterioration rate. Then if I assume that bridge is going to be replaced when it reaches a three then I can calculate the remaining life and then the bridge life is just how old is it now plus the remaining life.

“I looked at bridges built between 1960 and I cut it off at 2010. Then of course I needed to know everything that happened to every one of those bridges for it to be in the database.”

Penn DOT has over 25,000 bridges in their database and over 6,500 of those are the five types of bridges Barker identified in the study. He came up with a list of steel rolled beams, plate girder, box adjacent, box spread and prestressed I-beam bridges and found 1,700 bridges that met all the criteria.

Two of the bridge types, steel rolled bridges and precast box spread bridges, performed the best and second best respectively, however, there was not a big difference between the best performing and the worst performing bridge.

“For instance, steel rolled beam is 7.1 per cent of a condition rating loss per year and the worst is not that much worse than that,” said Barker. “All are similar with none way out of balance.”

He then looked at the agency lifecycle costs. He determined perpetual present value costs (PPVC), more commonly known as capitalized costs, in order to be able to compare the bridges directly.

“If we look at the average bridge life, steel rolled beam has the longest expected life and then precast box spread has second,” Barker noted. “The highest is over 81 years and the low is 74 years. That’s still not a big difference.”

Then he looked at cost.

“We see that for all the bridges for all the database, the precast I-beam has the lowest perpetual cost, steel rolled beam is second, but again none of them are way out of balance,” said Barker.

He narrowed it down further to look at short length bridges.

“When I narrow that down, we can see that the average length and the average number of spans becomes much more consistent, which means this is going to be a more consistent comparison,” he noted. “What are our results if we look under the PPVC or the capitalized costs? Now steel rolled beam is the least expensive and the precast box spread is next.

“If I take the overall weighted average capitalized costs, it comes out to be a little over than $252 per square foot,” he added. “All of the five different bridge types all of their averages are within 14 per cent of that.”

Betul Oliver, business development manager for eastern Canada with Acrow, talked about prefabricated steel and modular bridge systems. She referred to specific examples of where Acrow bridges can be used including for vehicular, long-span, beam, pedestrian, railroad and detour bridges. Some of the benefits include they are typically lighter in weight, can achieve longer spans, are easier to maintain and inspect and have quicker installation times, she said.

Follow the author on Twitter @DCN_Angela.

Recent Comments

comments for this post are closed